Carbon nanometer tube cement based composite material sensor encapsulating method

A technology of composite materials and carbon nanotubes, applied in the direction of instruments, measuring devices, measuring instrument components, etc., can solve the problems of high cost, difficult deployment and control, and difficult signal analysis, so as to reduce measurement errors, simple manufacturing methods, and reliable measurement data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

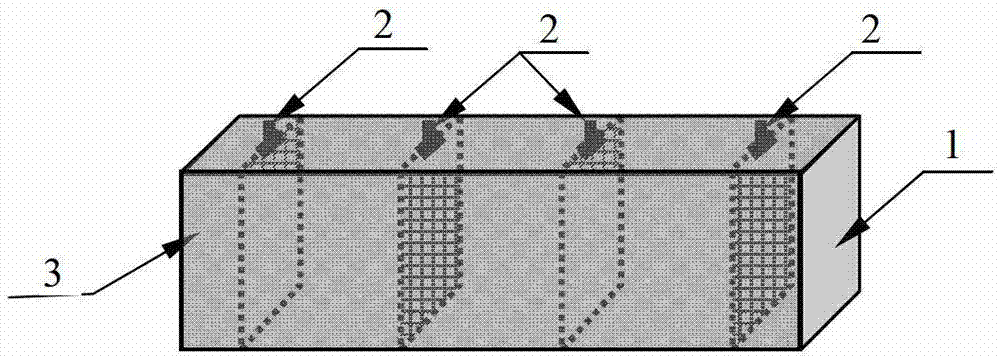

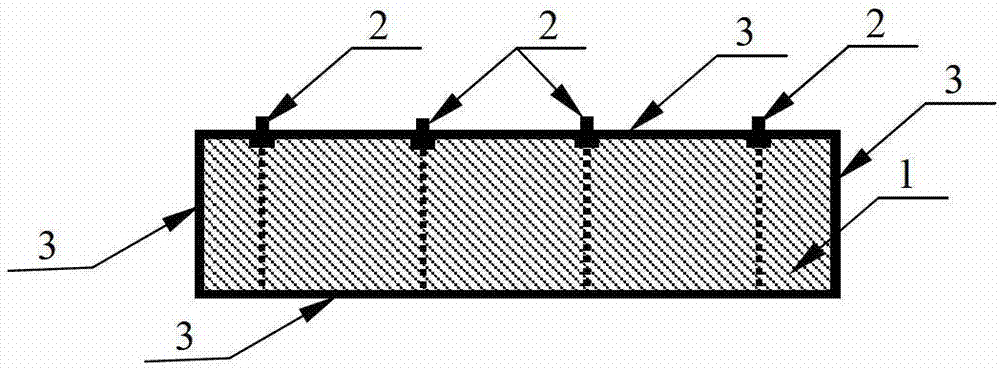

[0017] Embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0018] First, protect the metal terminal 2 of the carbon nanotube cement-based composite sensor, and cover the outside with a protective cover to prevent damage or contamination when applying adhesive or paint, and apply adhesive on each surface of the carbon nanotube cement-based composite sensor Or paint, such as epoxy resin, etc., carry out the making of coating 3, before the coating is completely hardened, roughen the surface to make the surface rough enough. Remove the protective sleeve of the carbon nanotube cement-based composite material sensor binding post, and the sensor coating can be used in engineering after it is completely hardened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com