A device and method for measuring the heating efficiency of a porous medium burner

A technology of porous media and heating efficiency, which is applied in the direction of measuring devices, lighting and heating equipment, instruments, etc., can solve the problems of difficult and accurate measurement of the heating efficiency of porous media burners, and achieve standardized measurement methods, accurate and reliable measurement data, and device Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

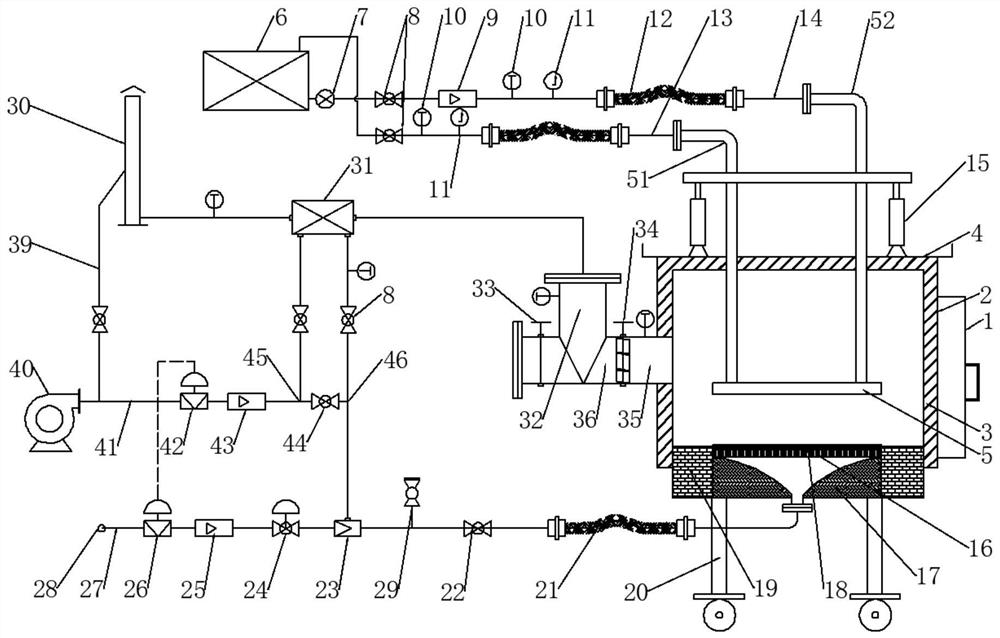

[0054] Embodiment 1: The present invention provides a device for measuring the heating efficiency of a porous medium burner, the structure of which is as follows: figure 1 shown. The device is equipped with a trolley-type test furnace, a porous medium burner, a movable water tank 5, a cylinder lifting mechanism 15, a water supply pipe network, an air supply pipe network, a smoke exhaust pipe network, a heat exchanger 31, a measurement system and a control system ; The measurement system is the flow meter, pressure gauge and thermocouple provided in the water supply pipe network, the gas supply pipe network and the smoke exhaust pipe network, and the described control system is used to control the water and gas regulation of each pipe network , the temperature, pressure and operating status of the console car-type test furnace.

[0055] The trolley-type test furnace is provided with a furnace shell 2, a furnace shell lining 3, a side-opening furnace door 1, a detachable furnac...

Embodiment 2

[0090] Example 2: The present invention uses the device for measuring the heating efficiency of a porous medium burner provided in Example 1, and its operation method is basically the same as that in Example 1, the only difference is the operation step 1), namely:

[0091] 1) Open the furnace door 1 of the trolley-type test furnace, move the trolley-type furnace bottom 20 to the outside of the furnace, and replace the material of the furnace shell lining 3 with a composite lining composed of clay bricks and diatomite bricks. After installing the porous medium burner in the cart-type furnace bottom, push the cart-type furnace bottom into the cart-type test furnace and close the furnace door; connect the mixed gas metal hose 21 on the mixed gas pipeline to the cart-type furnace bottom. Connect the inlet of the porous medium burner; adjust the distance between the movable water tank 5 in the furnace and the porous medium combustion panel 18; repeat the operation steps (2) to (9) i...

Embodiment 3

[0092] Example 3: Using the device for measuring the heating efficiency of a porous medium burner provided in Example 1 of the present invention, the operation steps are basically the same as those in Example 1, except that the operation step (5) is to adjust the movable water tank 5 in the furnace and the porous medium. The distance between the medium combustion panels 18, record the values of the parameters listed in step (4); also through the data obtained by measurement, the fuel combustion heat Q of the device can be sorted out through the heat balance formula 烧 and Q 效 , and further calculate the heating efficiency η of the porous medium burner according to formula ⑺, that is, the measurement of the heating efficiency of the porous medium burner is completed.

[0093] This example is to measure the heating efficiency of the porous medium burner under the variable angle coefficient.

[0094] The device of the invention is scientific and reasonable in design, and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com