Base plate packaging method

A packaging method and substrate technology, applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of complex manufacturing process, expensive equipment, poor ability to prevent water vapor and oxygen, etc., and achieve extended service life, strong operability, and packaging The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

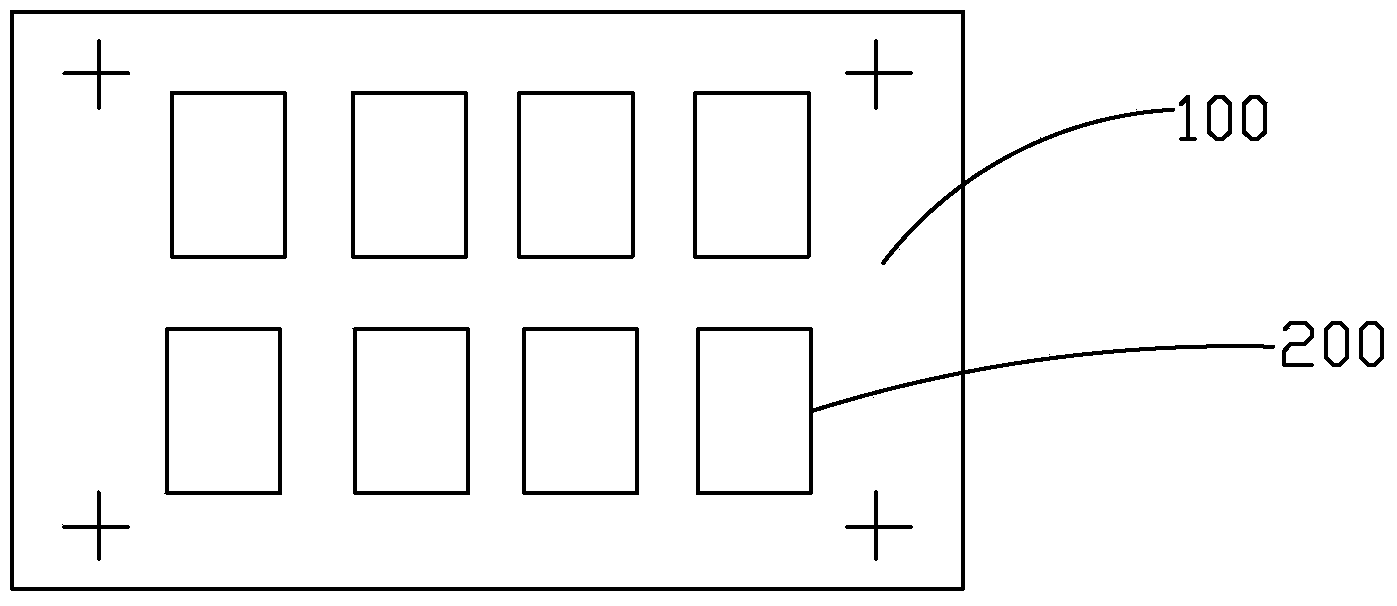

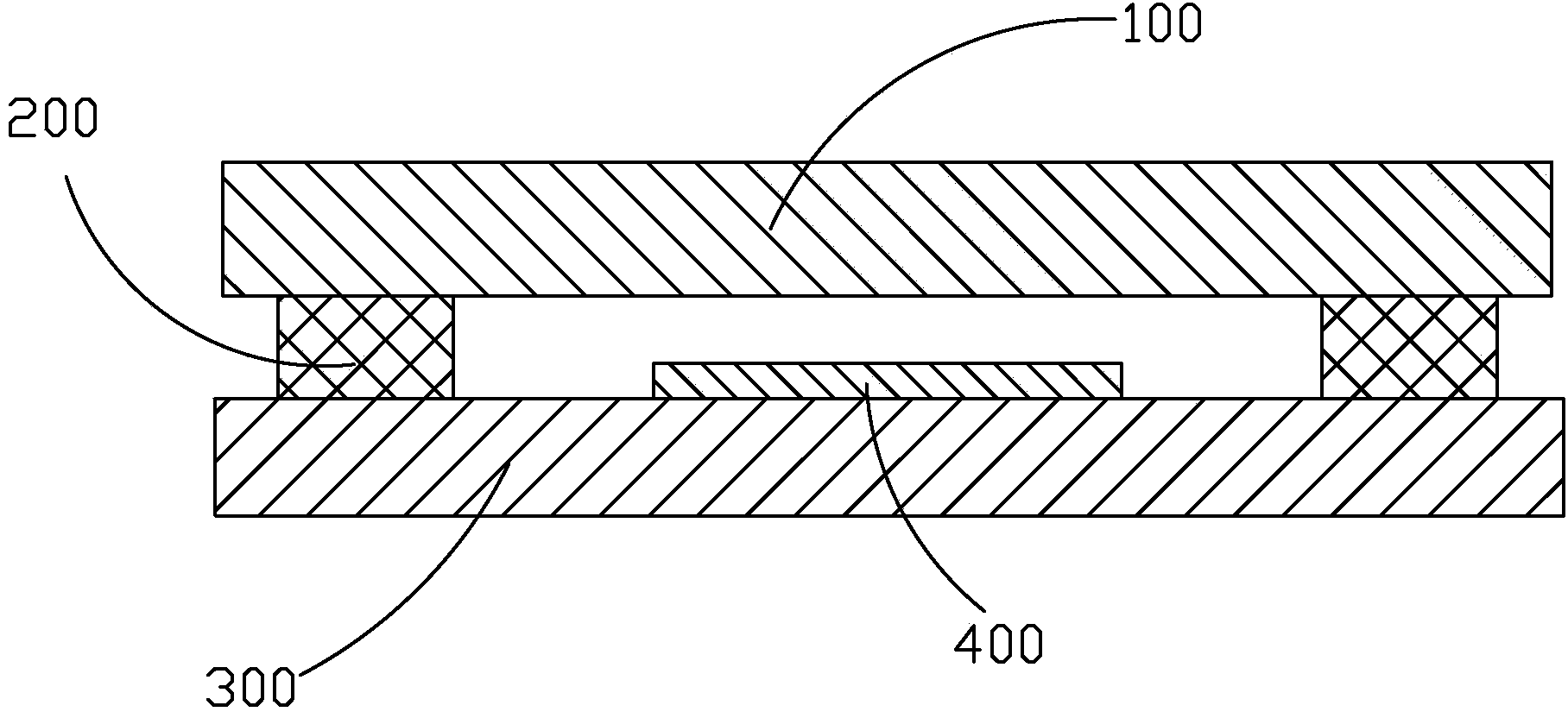

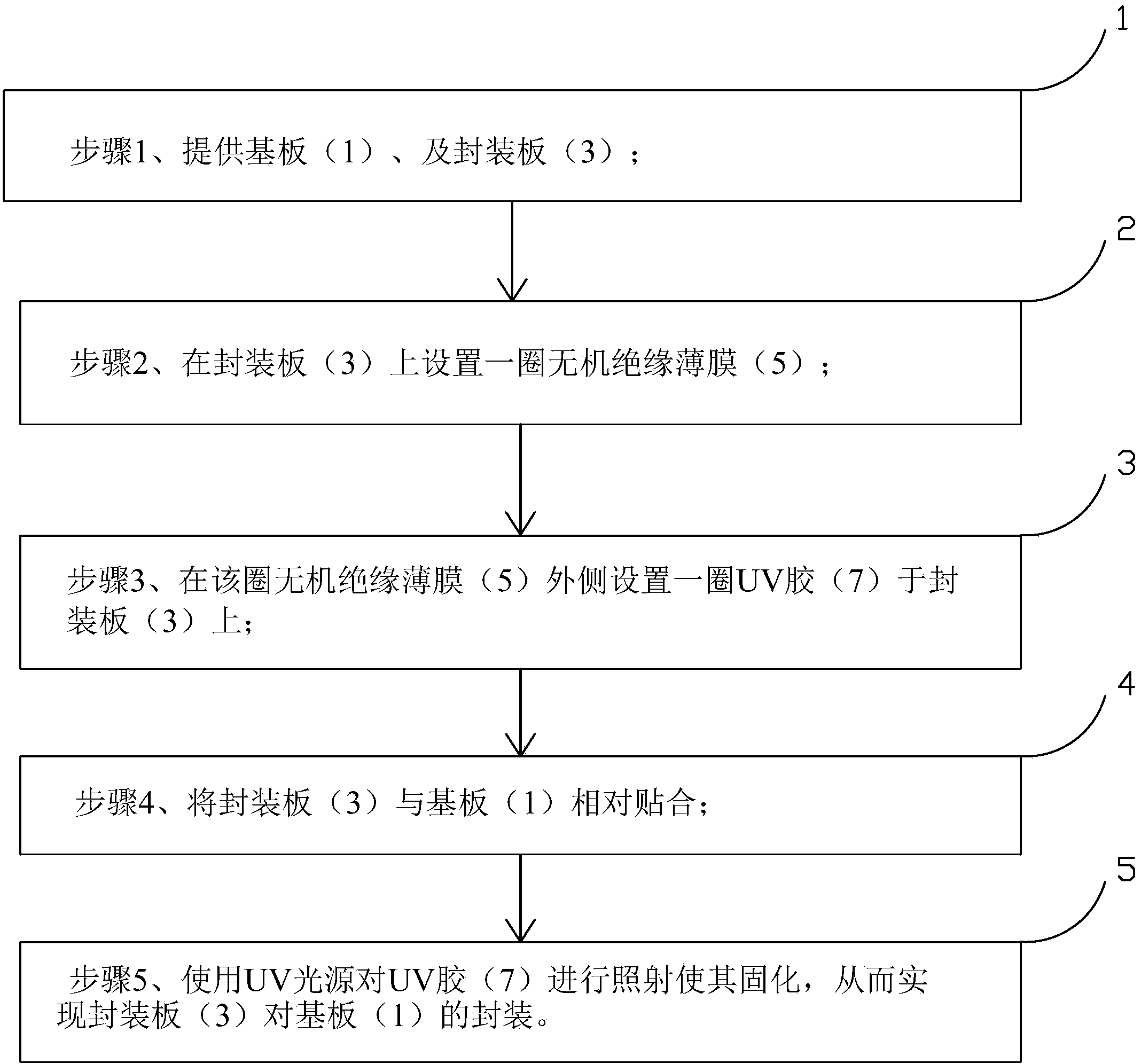

[0042] see Figure 3 to Figure 10 , the present invention provides a substrate packaging method, comprising the following steps:

[0043] Step 1, providing a substrate 1 and a packaging board 3;

[0044] Step 2, setting a circle of inorganic insulating film 5 on the packaging board 3;

[0045] Step 3, arrange a circle of UV glue 7 on the packaging board 3 outside the circle of inorganic insulating film 5;

[0046] Step 4, relatively attaching the packaging board 3 to the substrate 1;

[0047] Step 5, using a UV light source to irradiate the UV glue 7 to cure it, so as to realize the packaging of the substrate 1 by the packaging board 3 .

[0048] Specifically, the substrate 1 in the step 1 is a TFT substrate, and the packaging plate 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com