LED automobile lamp packaging method

A technology of LED car lights and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of high cost, and achieve the effects of saving costs, ensuring consistency, and simple and easy packaging methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments.

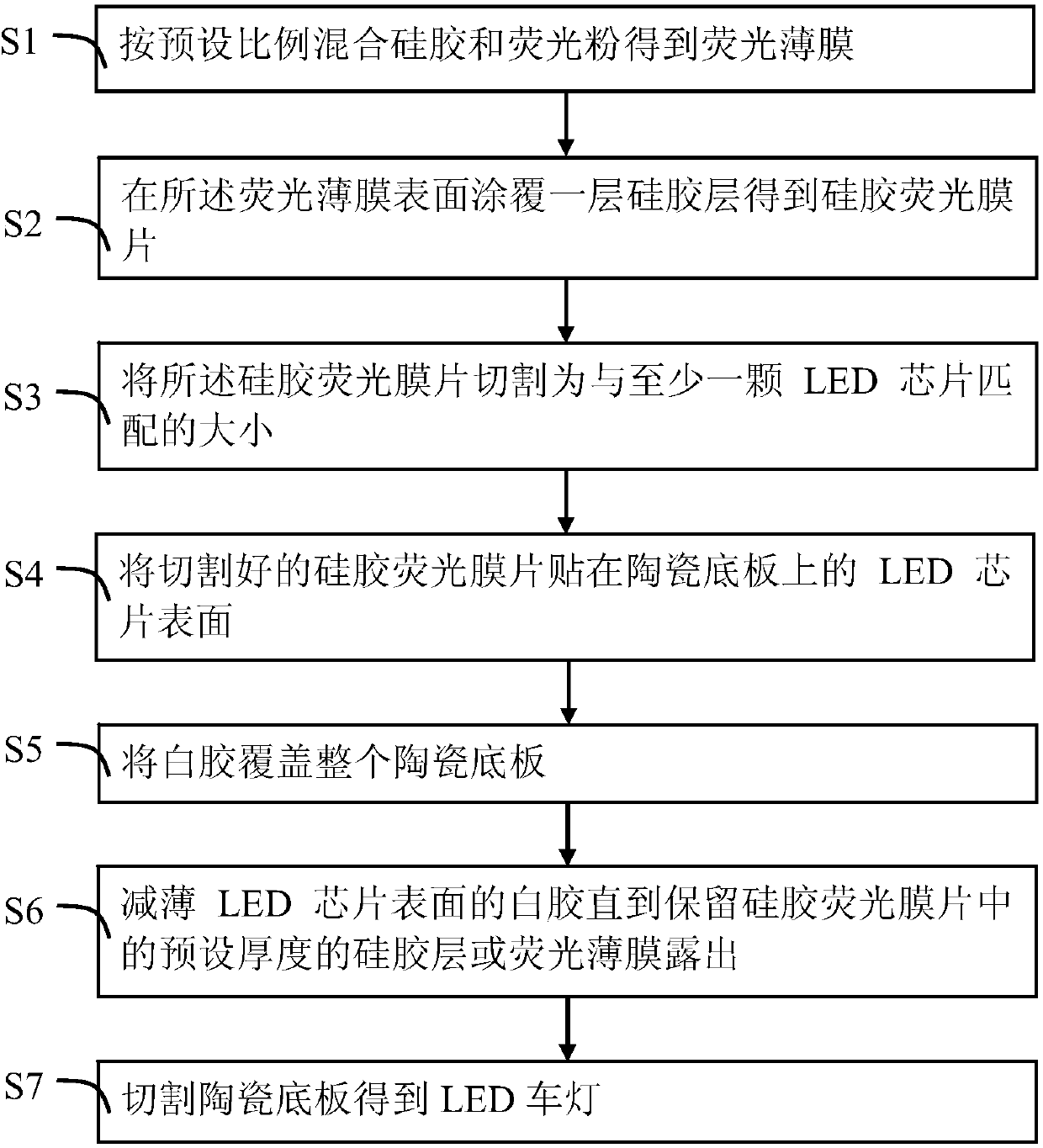

[0024] Such as figure 1 Shown is a schematic flow chart of the LED car lamp packaging method provided by this method. It can be seen from the figure that the LED car lamp packaging method includes: S1 mixing silica gel and phosphor powder in a preset ratio to obtain a fluorescent film; The surface of the film is coated with a layer of silica gel to obtain a silica gel fluorescent diaphragm; S3 cuts the silica gel fluorescent diaphragm to a size that matches at least one LED chip; S4 pastes the cut silica gel fluorescent diaphragm on the surface of the LED chip on the ceramic substrate ; S5 covers the entire ceramic bottom plate with white glue; S6 thins the white glue on the surface of the LED chip until the silicone layer or fluorescent film wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com