Encapsulating method of flexible OLED device

A packaging method and device technology, which is applied in the manufacture of electric solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve problems such as difficult processes, and achieve the effects of good water and oxygen isolation, short cycle time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the drawings, and detailed descriptions are made as follows.

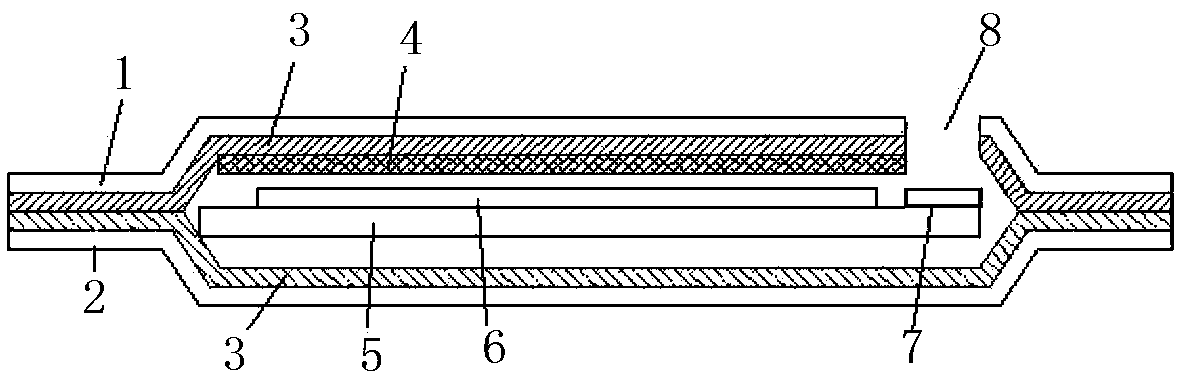

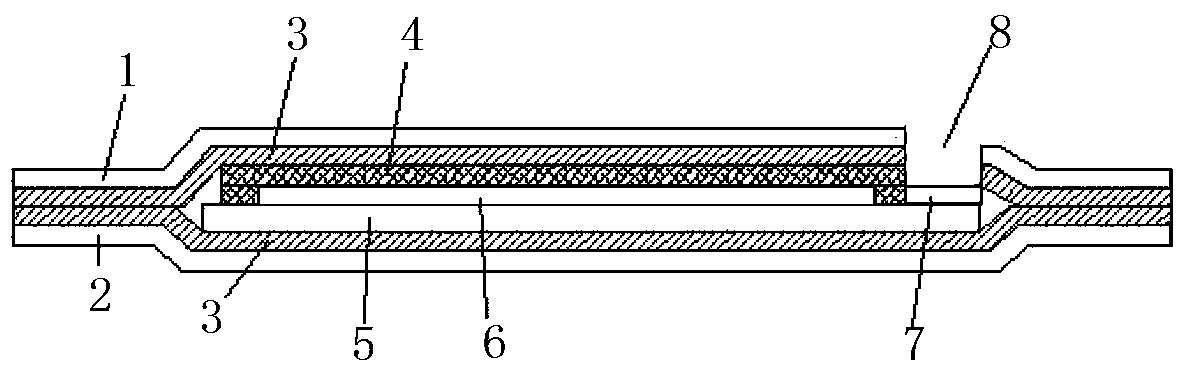

[0017] Such as Figure 1~2 As shown, a method for packaging a flexible OLED device, the packaging method is: (1) placing a pre-prepared OLED sample between two good barrier films; (2) stacking or stacking on top of the OLED sample Fabrication of getter layer 4; (3) Barrier film packaging is performed by hot-press bonding or adhesion, with fewer packaging procedures, reducing costs, avoiding the problem of low yield caused by the complexity of the packaging structure, and can effectively solve the problem at the same time The problem of water vapor and oxygen permeation can obtain efficient, stable and long-life devices under the guarantee of flexible OLED devices.

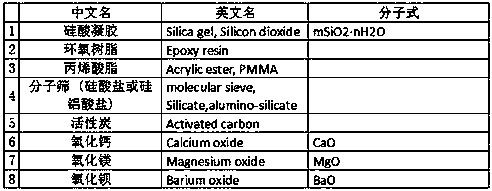

[0018] In the embodiment of the present invention, the barrier film is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com