Packing box and method for thin film solar cells

A technology of solar cells and packaging methods, applied in the field of solar cells, capable of solving problems such as bumping and shaking of thin-film solar cells, power attenuation of thin-film solar cells, failure of thin-film solar cells, etc., achieving a convenient packaging method, simple structure, and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

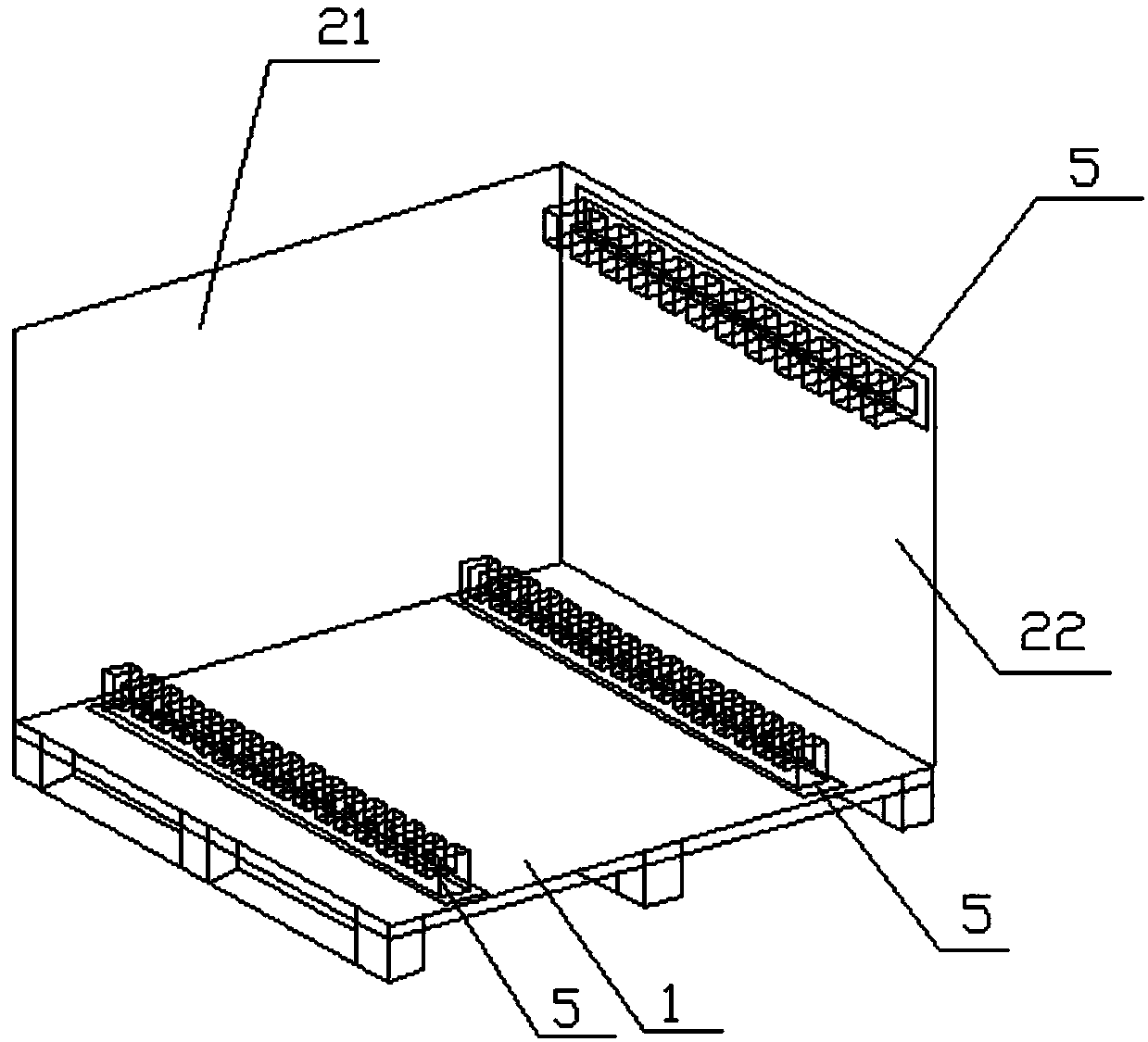

[0050] Such as Figure 1-8 Shown:

[0051] A packaging box for thin-film solar cells, comprising:

[0052] Tray 1, used to carry thin-film solar cells;

[0053]The outer shroud 2 is arranged on the outer side of the tray 1; the rear side of the outer shroud 2 includes: a vertically arranged first limiting plate 21 and a first side panel 23, and the first limiting plate 21 is set On the lower part of the first side panel 23; the right side of the outer wall 2 includes: a vertically arranged second limiting plate 22 and a second side panel 24, the second limiting plate 22 is arranged on the second side The lower part of the panel 24; the left side of the outer coaming board 2 is: the third side panel 25 arranged vertically; the front side of the outer coaming board 2 is: the fourth side panel 26 arranged vertically;

[0054] The box cover 3 is arranged on the top of the outer coaming plate 2;

[0055] Corner guards 4 are arranged at the corners of the outer panel 2;

[0056...

Embodiment 2

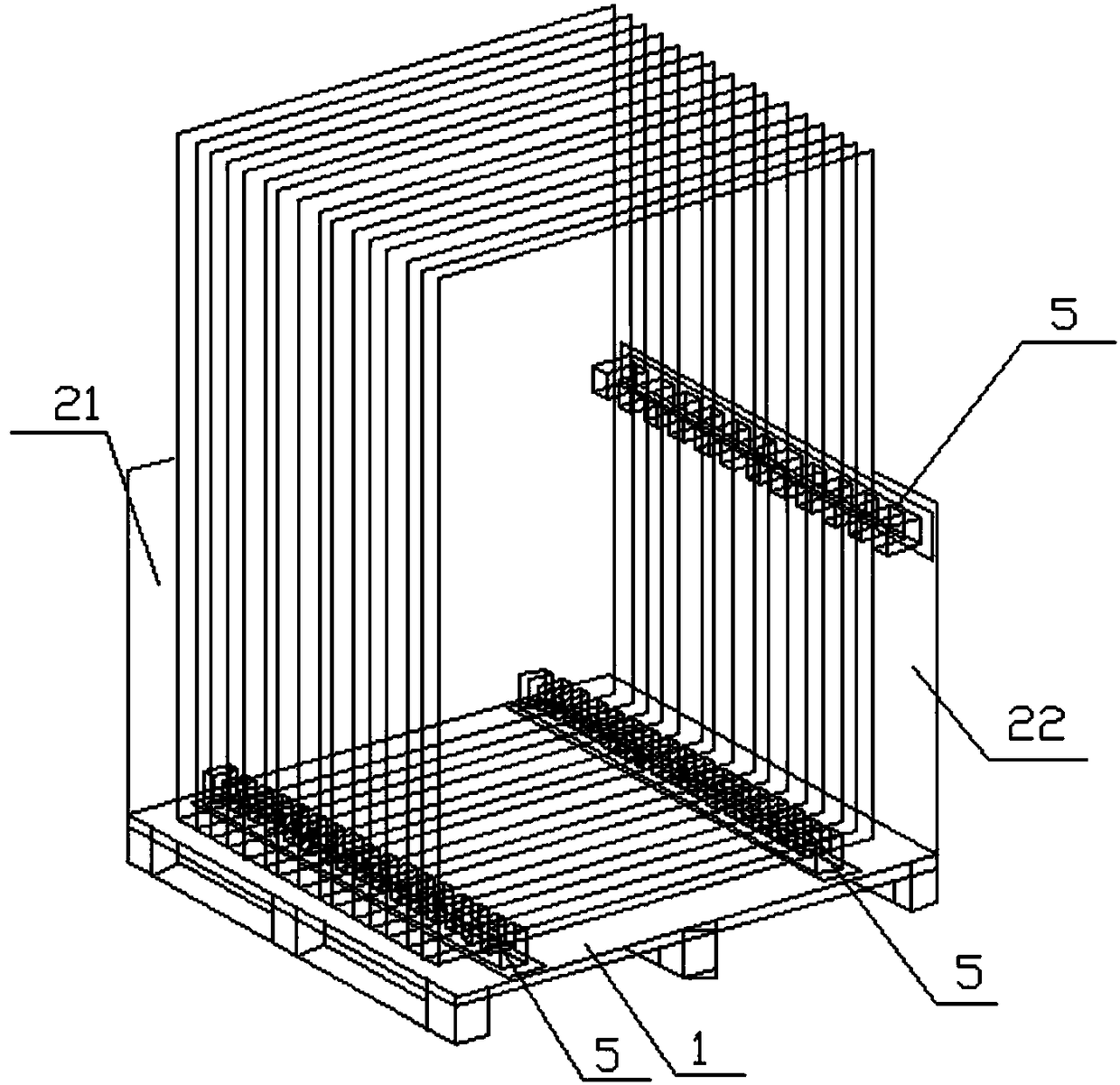

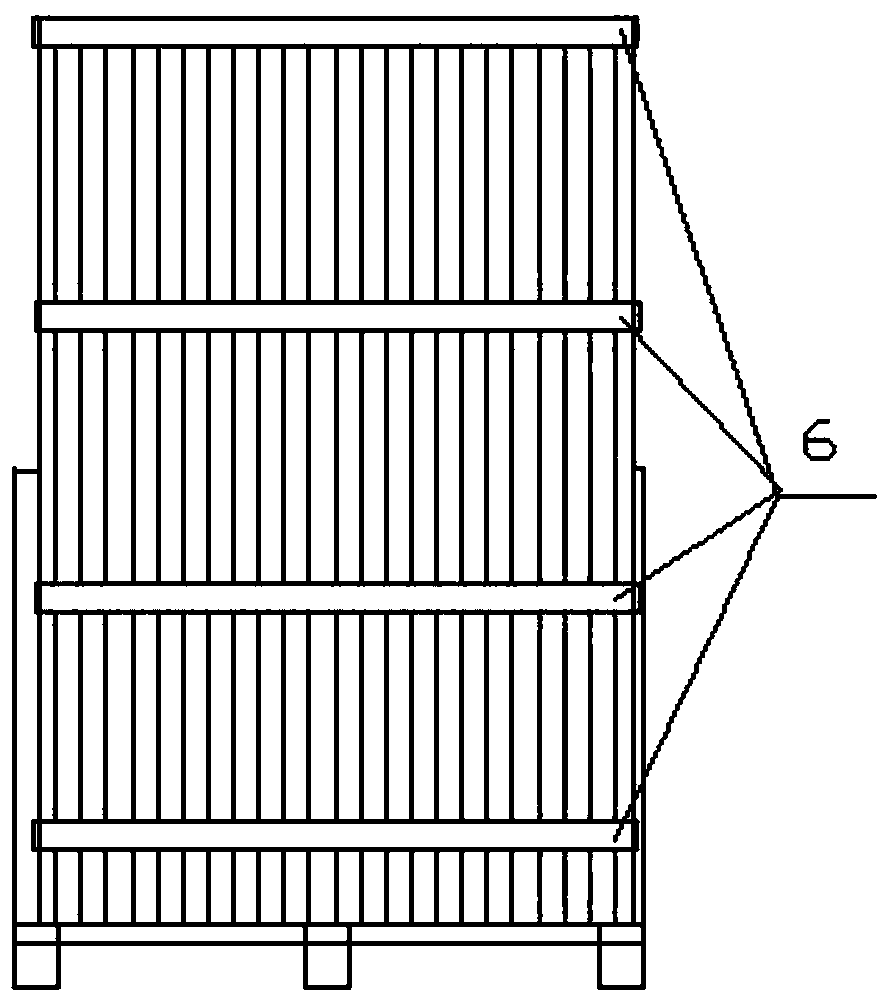

[0068] The difference between this embodiment and Embodiment 1 is that the limiting slot 5 and the protective slot 6 are elongated structures; the limiting slot 5 has a groove running through its width direction; The protection card slot 6 has a groove running through its width direction.

[0069] The protective card slot 6 is multi-layer corrugated cardboard; the protective card slot 6 is foamed PE. The first limiting plate 21 and the second limiting plate 22 are plywood. The first side panel 23, the second side panel 24, the third side panel 25 and the fourth side panel 26 are honeycomb paperboard. The corner guard 4 is a paper corner guard 4 .

[0070] The limiting slot 5 is adhesively connected to the upper part of the tray 1 and the left side of the second limiting plate 22 . Described protection draw-in groove 6, paste is connected in described case cover 3 bottoms, described second side panel 24 left side and described 3rd side panel 25 right sides. The pasting conn...

Embodiment 3

[0073] The only difference between this embodiment and embodiment 1 is that

[0074] A packaging method for thin film solar cells, comprising:

[0075] A) provide a pallet 1, the rear side of the pallet 1 is vertically provided with a first limiting plate 21, and the right side of the pallet 1 is vertically provided with a second limiting plate 22; The left side of the two limiting plates 22 is pasted and connected to the limiting card slot 5 .

[0076] B1) placing a plurality of thin film solar cells vertically on the tray 1 in turn;

[0077] B2) The lower right side and the bottom end of the thin film solar cell are engaged and fixed through the groove of the limit card slot 5; the limit card slot 5 is an elongated structure; the limit card slot 5 has a groove running through its width;

[0078] C) Engage and fix the left side, the upper end, and the upper right side of the thin film solar cell through the groove of the protection card slot 6; the protection card slot 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com