Semiconductor packaging through metallic bonding and method for same

A packaging method and a technology of metal bonds, which are applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of reducing the utilization rate of chips in semiconductor packages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

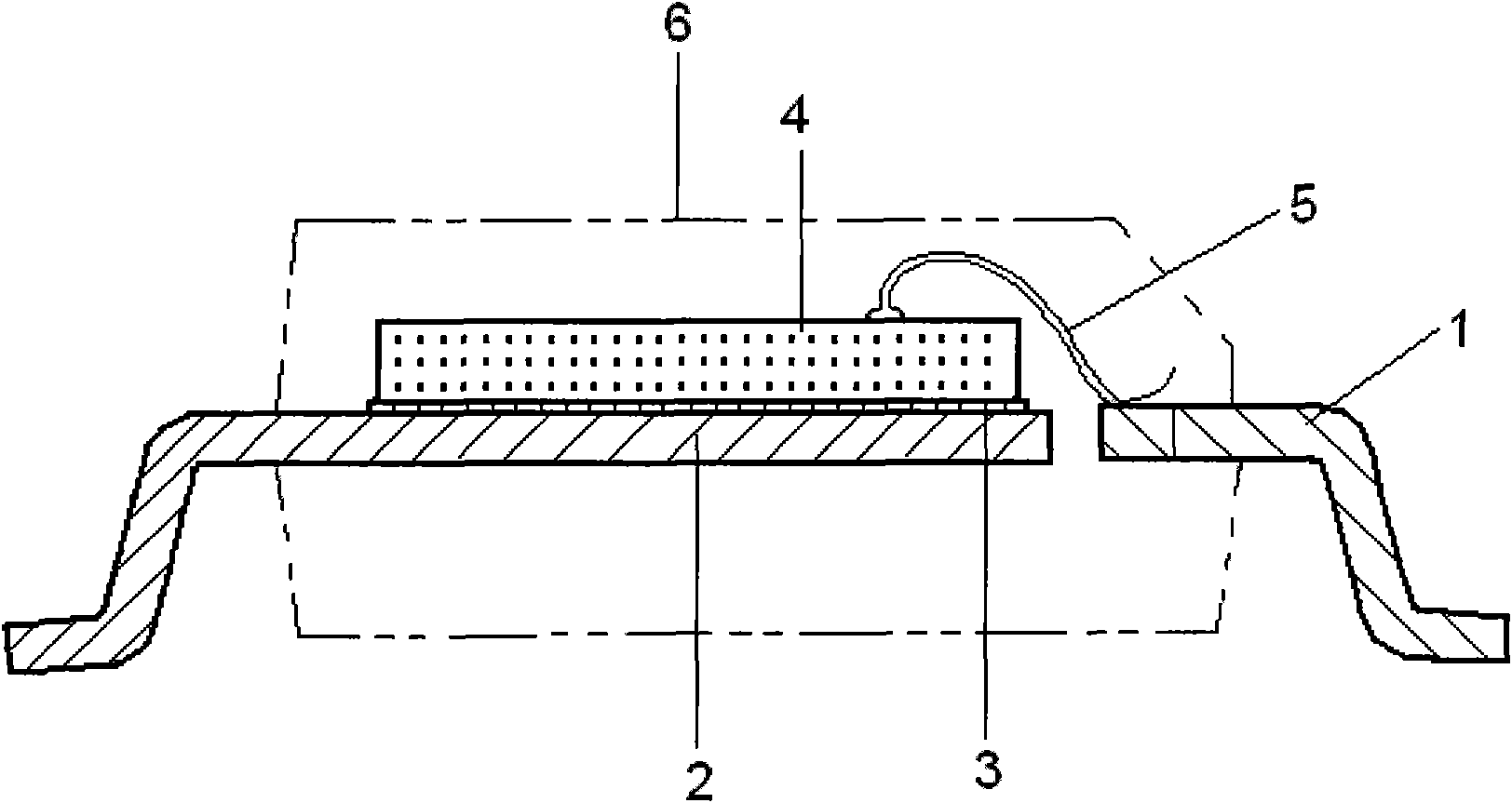

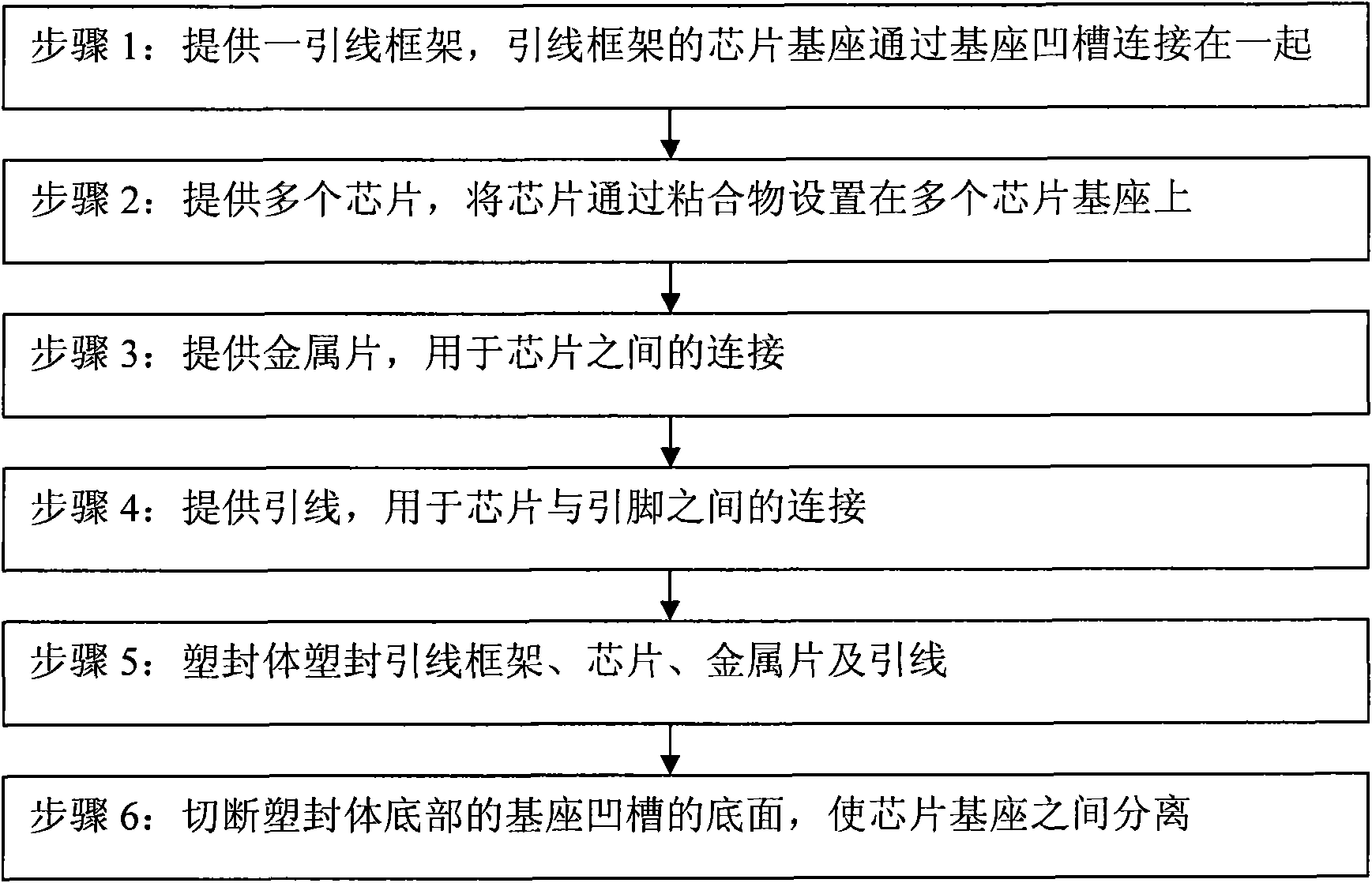

[0081] Embodiment 1: The present invention provides a metal sheet bonding packaging method. The packaging structure of the packaging method includes a lead frame 110, an adhesive 120, chips 130, 140, a metal sheet 150, a lead 160, and a plastic package 170. The flow chart of semiconductor packaging with metal sheet bonding is as follows: image 3 As shown, the specific encapsulation process is as follows:

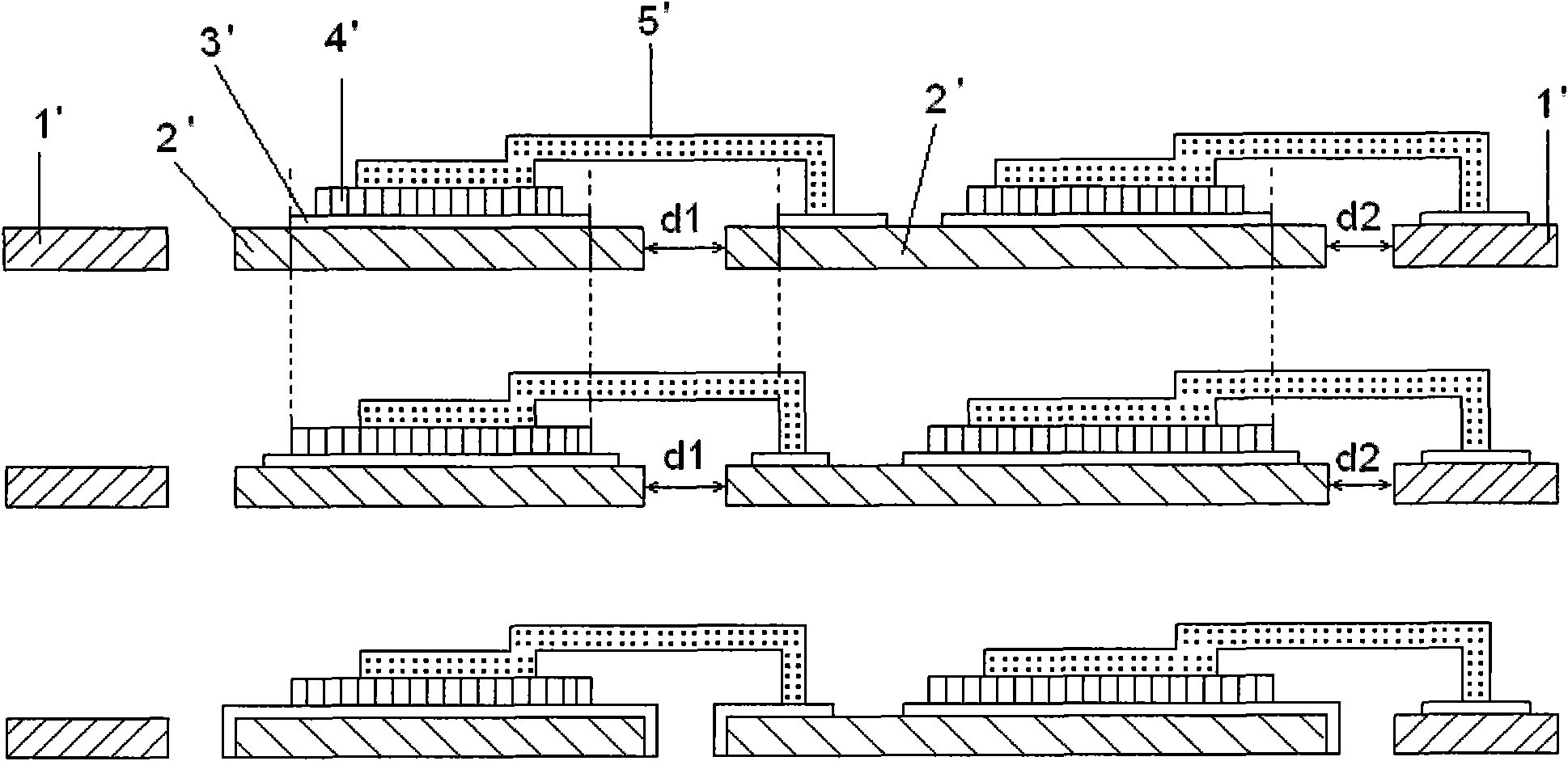

[0082] Such as Figure 4 As shown, firstly, a lead frame 110 is provided, and the lead frame 110 includes a chip base 115 and a plurality of pins. Figure 4 The upper figure is a top view of the lead frame, and the lower figure is a cross-sectional view along the dotted line in the previous figure. The chip base 115 includes a first chip mounting area 1151 , a second chip mounting area 1152 and a base groove 1153 . The base groove 1153 is disposed between the chip mounting areas and can distinguish each chip mounting area. In practical applications, multiple chip mountin...

Embodiment 2

[0089] Embodiment 2. The present invention provides a packaging method for metal sheet bonding. The packaging structure includes a lead frame 210, an adhesive 220, a chip 230, a metal sheet 240, a lead 250, and a plastic package 260. The semiconductor packaging method of the present invention Flowchart such as Figure 10 As shown, the specific packaging steps are as follows:

[0090] Such as Figure 11 As shown, a lead frame 210 is provided, and the lead frame 210 includes pins and a chip base 211 . The pins include two groups of pins 212 , 213 connected to the chip base 211 and arranged on both sides of the chip base 211 , and pins 214 disconnected from the chip base 211 . Such as figure 1 As shown, there is also a groove 215 between the base and the pins between the chip base 211 and the pins 213, and the groove 215 between the base and the pins separates the chip base 211 from the pins 213 Come.

[0091] Such as Figure 12 As shown, a chip 230 is provided, and the chi...

Embodiment 3

[0094] Embodiment 3. The above embodiment 1 is that the packaging structure connects each chip mounting area on the chip base before plastic sealing, and distinguishes them by base grooves. After the plastic sealing is completed, the base grooves are cut to complete the entire encapsulation process. The second embodiment is that the package structure connects the chip base and the pins together before plastic sealing, and distinguishes them by the groove between the base and the pins. After the plastic sealing is completed, the groove between the base and the pins is cut to complete the whole Encapsulation process. In a specific packaging process, Embodiment 1 and Embodiment 2 can be combined. Such as Figure 17 As shown, metal sheets are used instead of lead wires to connect the chip electrodes and pins, and the chip bases 311 in the lead frame 310 and between the chip bases 311 and the pins 312 are all connected together, and the base grooves 313 are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com