A kind of led vacuum encapsulation device and vacuum encapsulation method

A technology of vacuum packaging and vacuum pumping device, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unqualified packaged products, reduce LED light efficiency, affect LED light output, etc., and achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

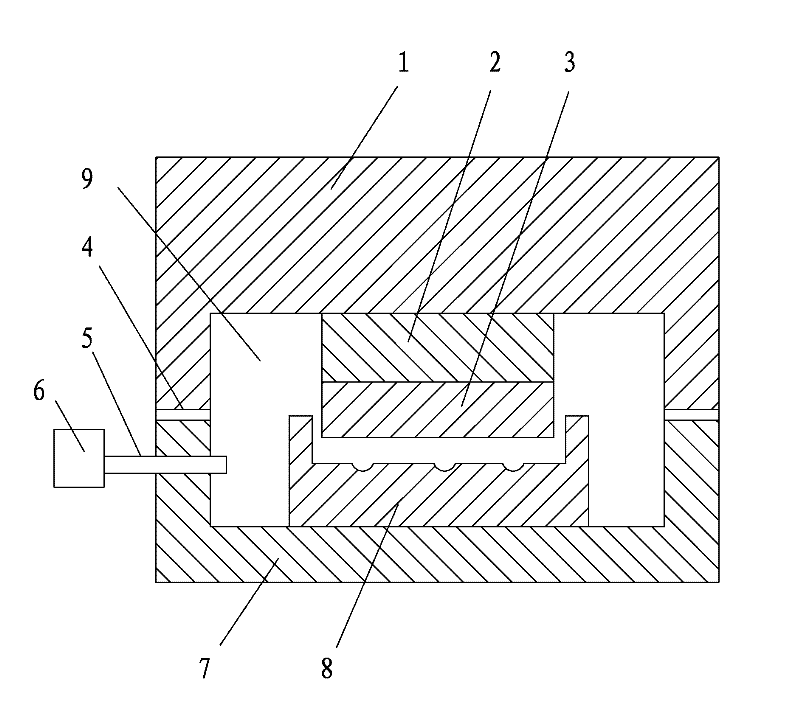

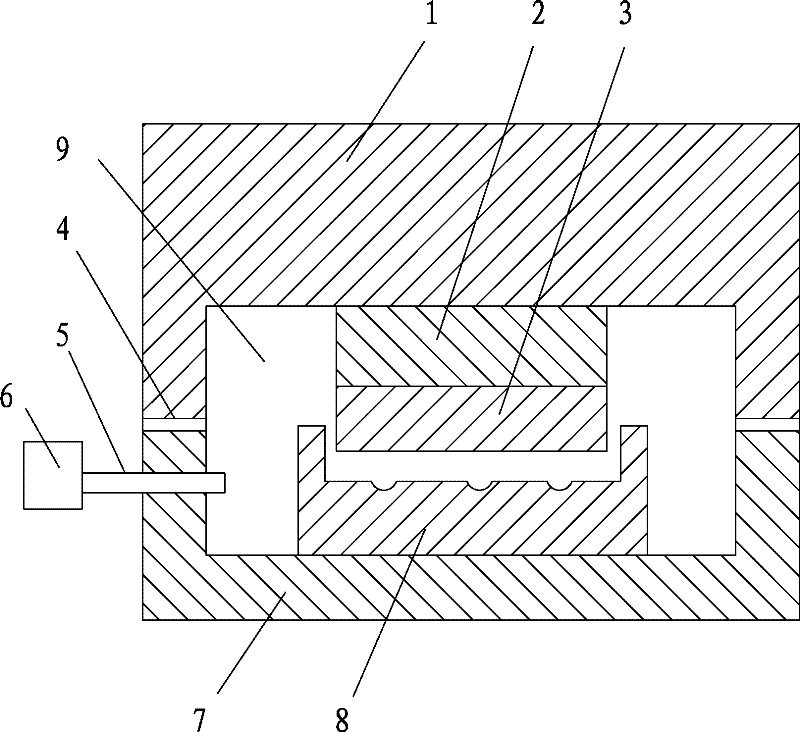

[0033] A kind of LED vacuum packaging device, such as figure 1 As shown, it includes a substrate 3 and a molding die 8, the substrate 3 is arranged above the molding die 8, the substrate 3 matches the molding die 8, and the vacuum packaging device is also provided with an upper mold 1 and a lower mold 7. The upper mold 1 and the lower mold 7 are matched with each other to form a sealed mold cavity 9, the base plate 3 and the forming mold 8 are arranged in the mold cavity 9, and the mold cavity 9 communicates with a vacuum pumping device. The upper mold 1 and the lower film 7 are buckled together, and the sealing gasket 4 is used to assist the sealing between the upper mold 1 and the lower film 7, which can ensure that the mold cavity 9 is in a vacuum environment after air extraction.

[0034] The air in the mold cavity 9 is drawn out by a vacuum pumping device. During the pressing process of the substrate 3 and the forming mold 8, the mold cavity 9 is in a vacuum environment, ...

Embodiment 2

[0042] A LED vacuum packaging method, comprising the following steps:

[0043] Step 1, inject glue, use glue injection equipment to pre-inject into the molding die 8 according to the required amount of glue injection;

[0044] Step 2, close the mold, close the upper mold 1 and the lower mold 7, the vacuum machine 6 works, vacuumize the mold cavity 9 through the vacuum tube 5, and drive the motor 2 to press the substrate 3 at the same time, and suppress the injected encapsulation glue;

[0045] Step 3, the substrate 3 extrudes the encapsulation glue, and the encapsulation glue flows into the die hole of the molding die 8;

[0046] Step 4. When the encapsulation glue changes from liquid to solid state, open the upper mold 1, lift up the substrate 3, and the encapsulation glue sticks to the surface of the substrate 3, and the LED encapsulation molding is completed.

[0047] Compared with the prior art, the present invention proposes LED packaging in a vacuum environment, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com