Package structure and packaging process

A technology of packaging structure and electronic components, applied in the direction of circuit heating devices, electrical components, circuits, etc., can solve the problems of complex packaging structure, poor heat dissipation efficiency of traditional packaging structure, high cost of packaging method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

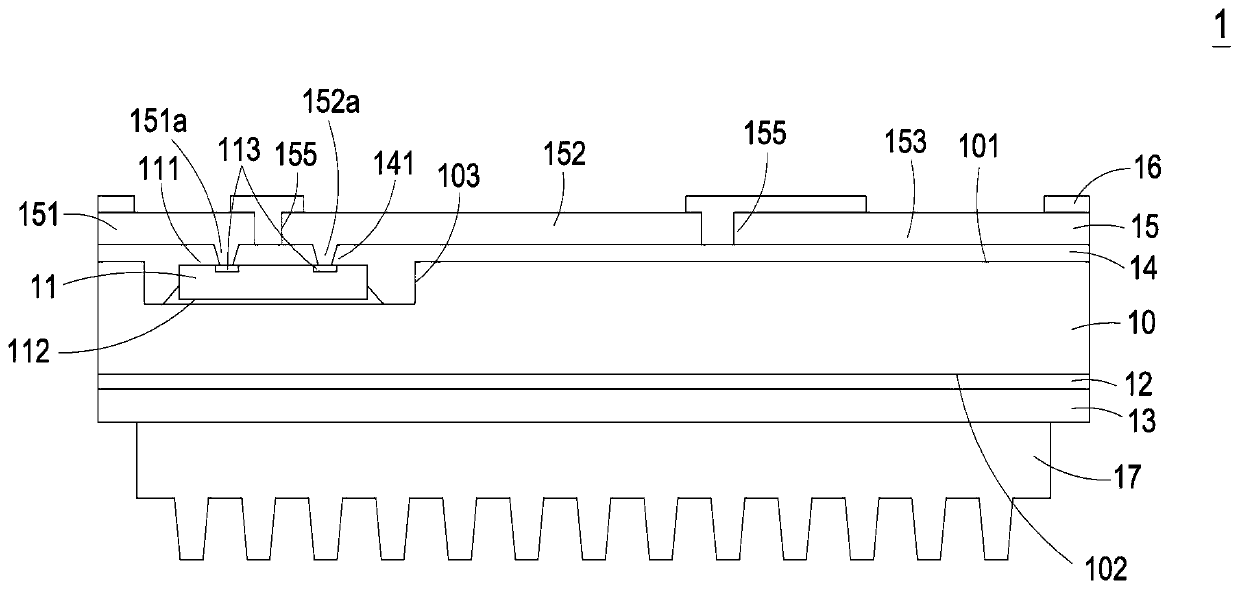

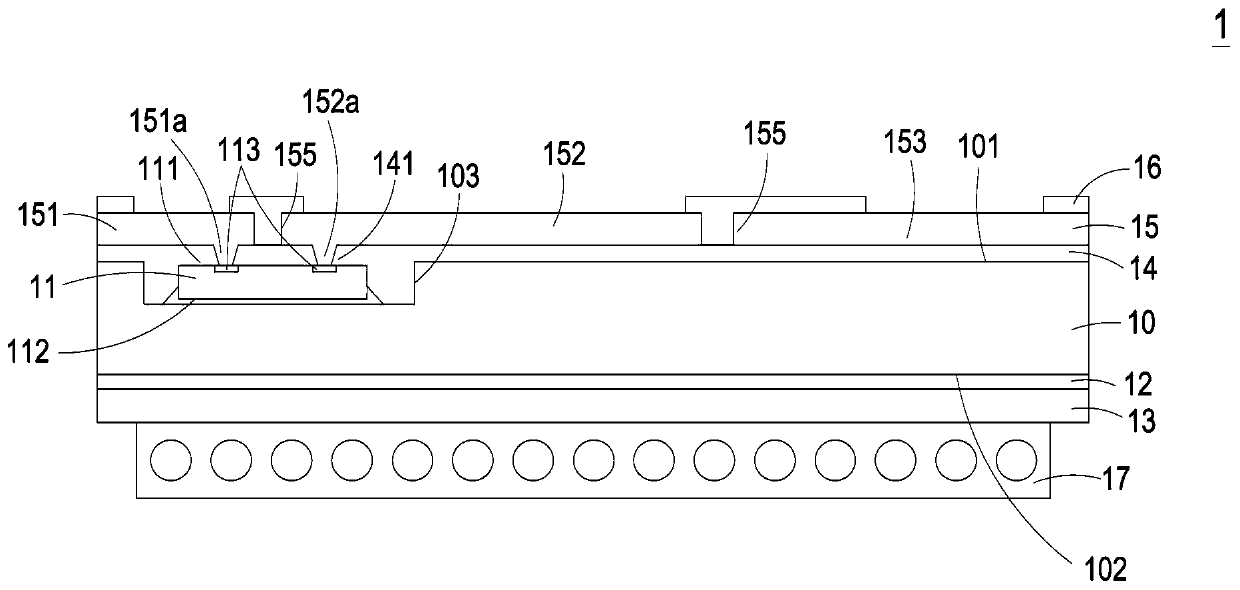

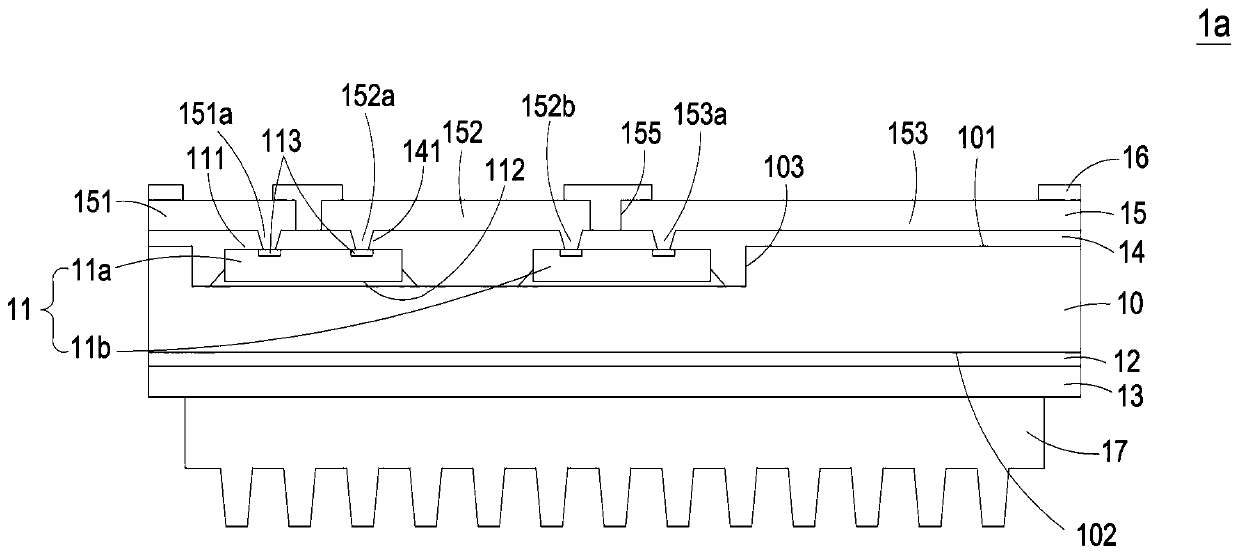

[0056] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different ways, which do not depart from the scope of the present invention, and the descriptions and diagrams therein are essentially for illustrative purposes, rather than being constructed to limit the present invention. invention. For example, if the following disclosure in this specification describes forming a first feature on or above a second feature, it means that it includes an embodiment in which the formed first feature and the second feature are in direct contact It also includes embodiments in which additional features can be formed between the first feature and the second feature, so that the first feature and the second feature may not directly contact. In addition, different embodiments in the description of the present invention ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com