Surface mount microwave device and packaging process thereof

A microwave device and surface mount technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of increasing packaging costs, inability to disassemble, reassemble or repair, etc., to increase and improve the application level Effective dielectric constant and distribution parameter elimination effect of circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

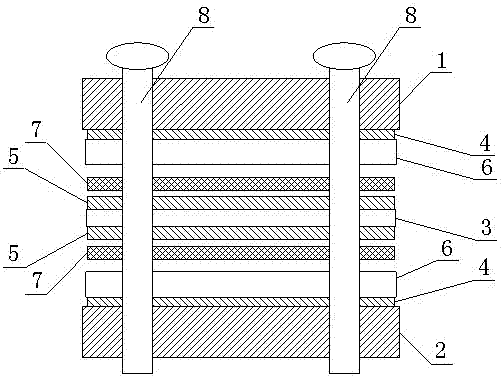

[0035] Such as figure 1 As shown, the surface mount microwave device includes an upper cover 1, a lower cover 2 and a central dielectric material layer 3, between the upper cover 1 and the central dielectric material layer 3, the lower cover 2 and the central dielectric material layer 3 The copper foil layer 4 and the copper foil circuit layer 5 are arranged symmetrically between them, the copper foil layer 4 is arranged on the side close to the upper and lower cover plates, and the copper foil circuit layer 5 is arranged on the side close to the central dielectric material layer 3, A dielectric material layer 6 is also provided between the copper foil layer 4 and the copper foil circuit layer 5 , and a laminated adhesive film layer 7 for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com