Packaging method of Ni@ZSM-5 bifunctional catalyst

A dual-function catalyst, ZSM-5 technology, applied in catalysts, molecular sieve catalysts, carbon compound catalysts, etc., to achieve the effect of broadening the scope of application, short process, and fast and simple packaging method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A Ni@ZSM-5-25 bifunctional catalyst encapsulation method includes the following steps:

[0063] This embodiment adopts SiO with FAU structure 2 / Al 2 o 3 The HY molecular sieve of =5.0 is the aluminum source;

[0064] solid silica (SiO 2 ), SiO 2 / Al 2 o 3 =5 HY molecular sieve, Ni-ethylenediamine complex solution, tetrapropyl ammonium hydroxide (TAPOH), and deionized water (H 2 O) mix homogeneously, obtain mixed material, the mol ratio of each raw material in described mixed material is: SiO 2 / Al 2 o 3 =25, TAPOH / SiO 2 =0.5,H 2 O / SiO 2 =10, Ni element / SiO 2 =0.02;

[0065] Transfer the mixed material into a crystallization kettle at 170°C for 12 hours, take it out, filter it, and dry it; then bake it at 550°C for 5 hours; finally, in a hydrogen atmosphere, reduce it at 500°C for 8 hours to obtain Ni@ZSM-5 -25 bifunctional catalyst named A-1.

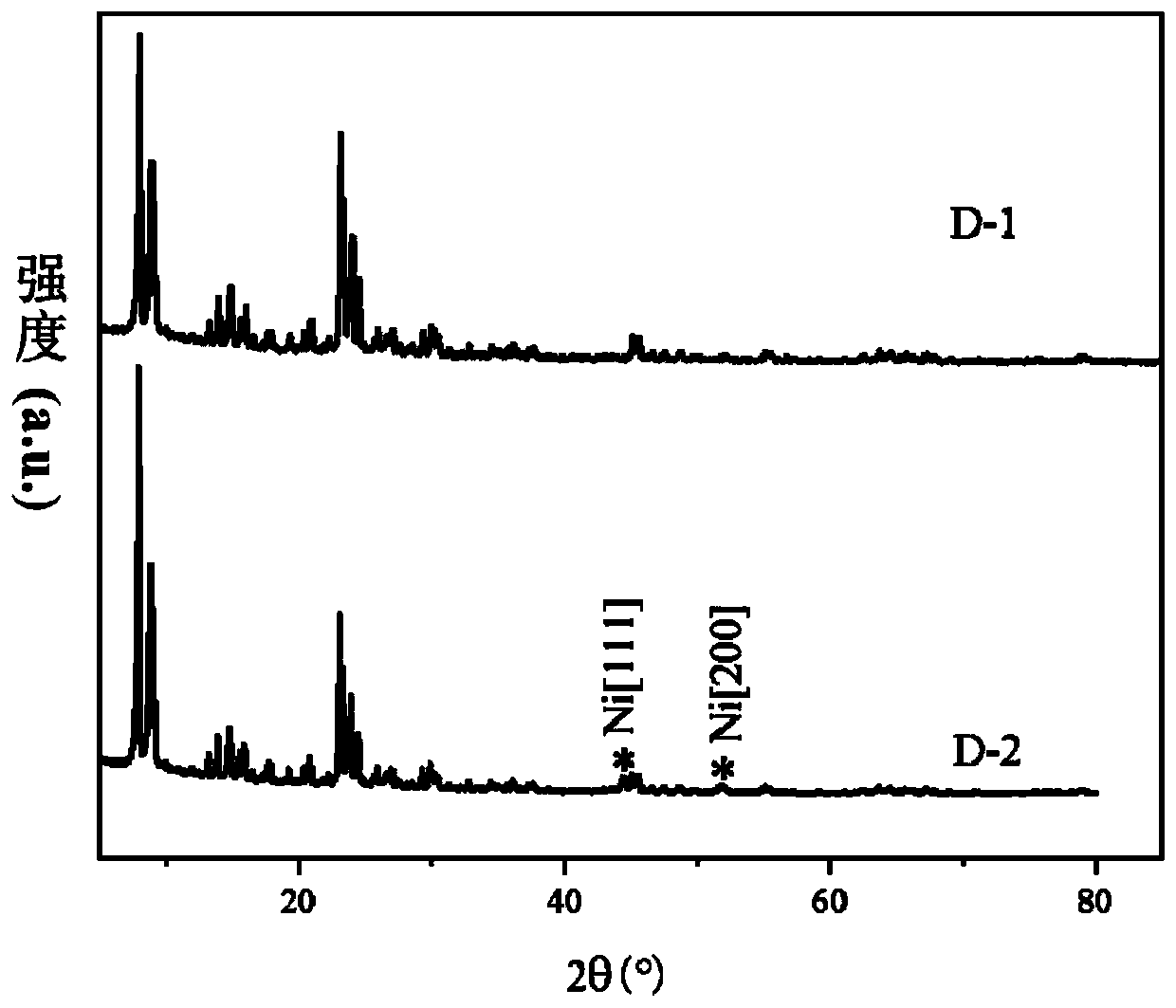

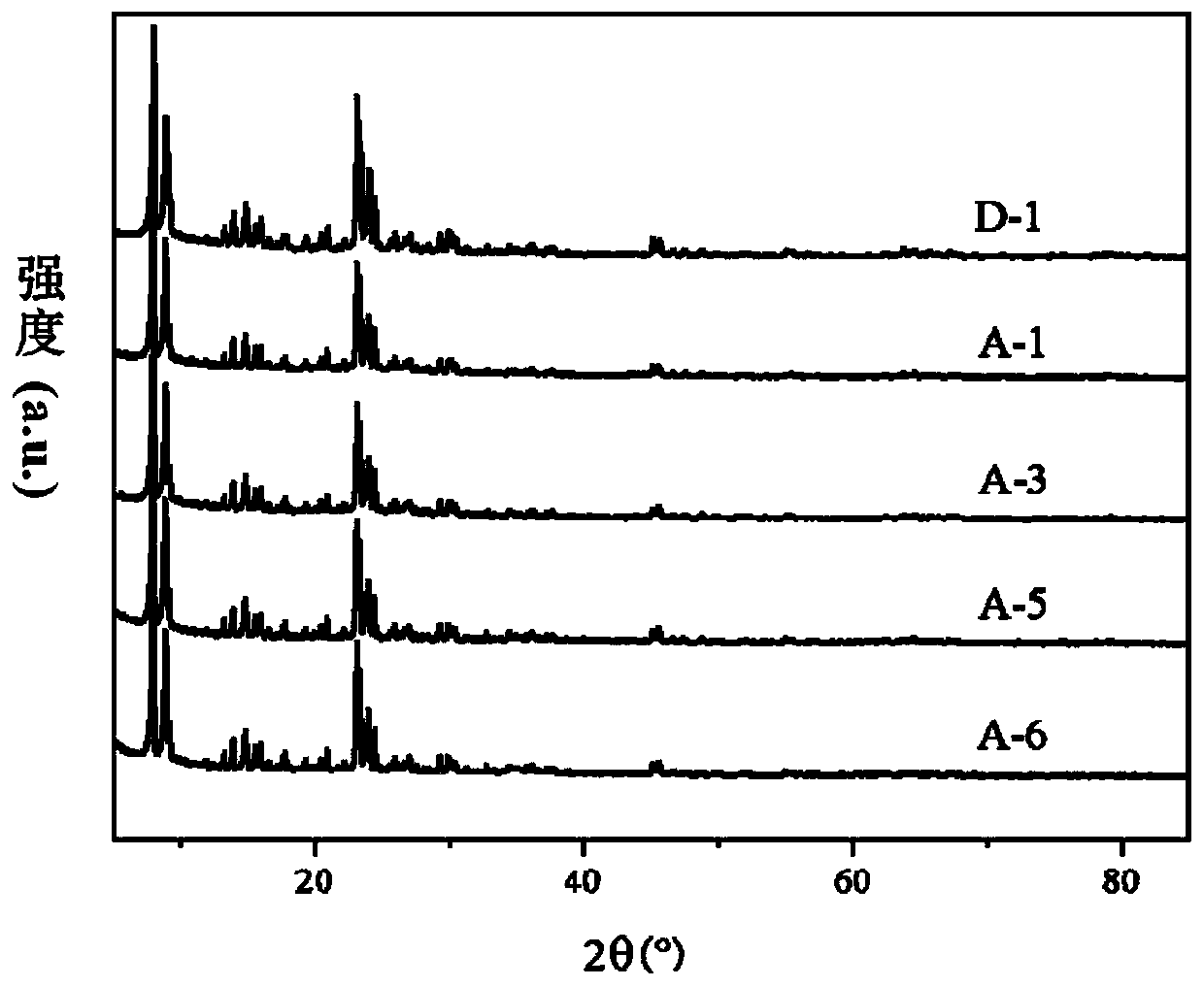

[0066] The XRD analysis of the Ni@ZSM-5-25 bifunctional catalyst obtained in this example is as follows figu...

Embodiment 2

[0068] A Ni@ZSM-5-50 bifunctional catalyst encapsulation method comprises the following steps:

[0069] This embodiment adopts SiO with FAU structure 2 / Al 2 o 3 The HX molecular sieve of =2.0 is aluminum source;

[0070] Mix white carbon black, HX molecular sieve, Ni-ethylenediamine complex solution, tetrapropyl ammonium hydroxide and deionized water evenly to obtain a mixed material. The molar ratio of each raw material in the mixed material is: SiO 2 / Al 2 o 3 =50, TAPOH / SiO 2 =0.3,H 2 O / SiO 2 =30, Ni element / SiO 2 =0.02;

[0071] Transfer the mixed material into a crystallization kettle at 170°C for crystallization treatment for 12 hours, take it out, filter it, and dry it; then bake it at 550°C for 5 hours; finally, in a hydrogen atmosphere, reduce it at 500°C for 4 hours to obtain Ni@ZSM-5 -50 bifunctional catalyst, named A-2.

[0072] The XRD of the Ni@ZSM-5-50 bifunctional catalyst obtained in this example observed the characteristic diffraction peak of ZSM-...

Embodiment 3

[0074] A method for encapsulating a Ni@ZSM-5-100 bifunctional catalyst comprises the following steps:

[0075] This embodiment adopts SiO with FAU structure 2 / Al 2 o 3 The NiX molecular sieve of =2.0 is as aluminum source and nickel source;

[0076] Mix and stir white carbon black, NiX molecular sieve, tetrapropylammonium hydroxide and deionized water evenly to obtain a mixed material. The molar ratio of each raw material in the mixed material is: SiO 2 / Al 2 o 3 =100, TAPOH / SiO 2 =0.2,H 2 O / SiO 2 =45, Ni element / SiO 2 =0.02;

[0077]Transfer the mixed material into a crystallization tank with a crystallization treatment at 170°C for 12 hours, take it out, filter it, and dry it; then bake it at 550°C for 5 hours; finally, in a hydrogen atmosphere, reduce it at 500°C for 4 hours to obtain Ni@ZSM - 5-100 bifunctional catalyst named A-3.

[0078] The XRD of the Ni@ZSM-5-100 bifunctional catalyst obtained in this example is as follows figure 2 Shown in (A-3): observe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com