Method for encapsulating light-emitting diode (LED), LED and LED illumination device

A LED packaging and LED chip technology, applied in the field of lighting, can solve the problems of difficult process control, easy interface, and many steps, and achieve the effect of easy control, simple packaging method, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

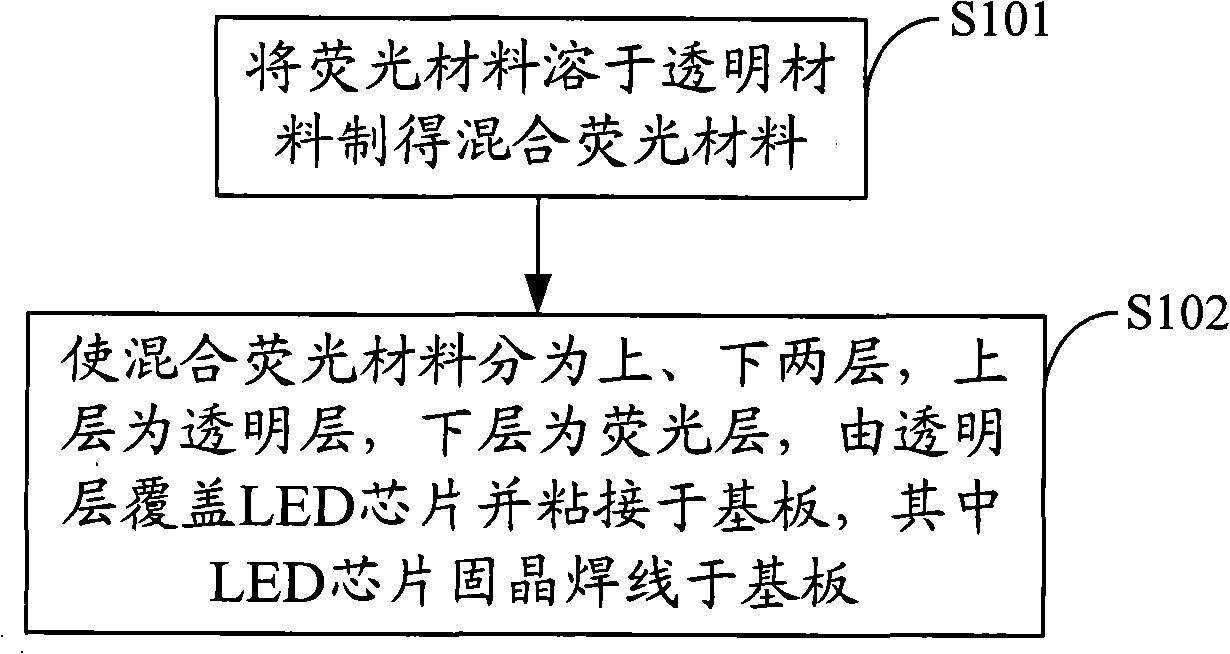

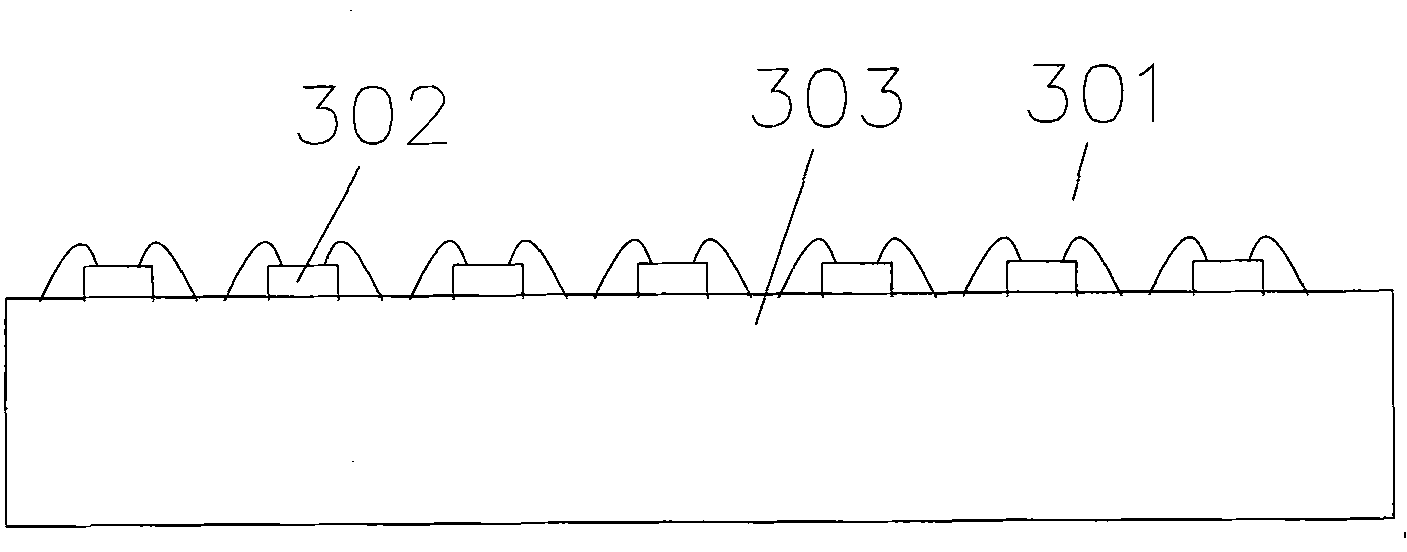

[0031] figure 1 The implementation flow of the LED packaging method provided by the first embodiment of the present invention is shown, and the details are as follows:

[0032] In step S101, the fluorescent material is dissolved in a transparent material to obtain a mixed fluorescent material;

[0033] In the embodiment of the present invention, the transparent material is a polymer transparent material, and the polymer transparent material is a thermosetting polymer material, such as silica gel, epoxy resin or modified silica gel or epoxy resin. The fluorescent material is fluorescent powder such as yellow fluorescent powder, green fluorescent powder, and red fluorescent powder.

[0034] Such as figure 2 As shown, after mixing components A and B of the thermosetting polymer material, according to market demands, an appropriate amount of fluorescent powder is added and stirred evenly to obtain the first mixed fluorescent material 201 .

[0035] For example, the A / B compone...

Embodiment 2

[0043] Figure 6 The implementation process of the LED packaging method provided by the second embodiment of the present invention is shown, and the details are as follows:

[0044] In step S601, dissolving the fluorescent material in a transparent material to obtain a second mixed fluorescent material;

[0045] In the embodiment of the present invention, the transparent material is a polymer transparent material, and the polymer transparent material is a thermoplastic polymer material, such as PS (Polystyrene, polystyrene), PMMA (Polymethyl Methacrylate, polymethyl methacrylate), TPX ( 4-methylpentene-1, poly 4-methylpentene-1) or PC (Polycarbonate, polycarbonate). The fluorescent material is fluorescent powder such as yellow fluorescent powder, green fluorescent powder, and red fluorescent powder.

[0046] First, dissolve the thermoplastic polymer material with anhydrous organic solvent (such as absolute ethanol, xylene, etc.). Then, according to the market demand, add an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com