Vinyl polymer nano composite material containing polar side group and preparation method thereof

A technology of vinyl polymers and nanocomposites, which is applied in the field of vinyl polymer nanocomposites and its preparation, can solve the problem that the thermal stability of polymer materials is not obvious, the effect of increasing thermal decomposition temperature is limited, and nano Clay is prone to agglomeration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Dissolve 1g of ethylene-vinyl acetate copolymer (referred to as EVA, ethylene content: 40mol%, number average molecular weight: 36000g / mol) in methanol (mass concentration: 25%), and add 5mol equivalent to the molar number of VA units in EVA % sodium hydroxide / alcohol solution, alcoholysis / saponification reaction at 65°C for 3 hours, to make a vinyl copolymer / methanol solution containing hydroxyl groups in side groups (abbreviation: component A / methanol solution), in which ethylene in component A The content is 40 mol%, and the vinyl alcohol structural unit content is 60 mol%.

[0052] At 60 ° C, the modified nano-montmorillonite (component B, DK2), 2,6-di-tert-butyl-4-methylphenol (component C) and methanol to form a mixed suspension, and further mixed with the above-mentioned components Part A / methanol solution was mixed for 5min to form a low-viscosity suspension containing component A, component B, component C and methanol / water, wherein the mass ratio of component ...

Embodiment 2

[0058] 1g of ethylene-vinyl acetate copolymer (abbreviated as EVA, ethylene content: 37mol%, number average molecular weight: 53000g / mol) was dissolved in methanol (mass concentration: 25%), and 4mol equivalent to the molar number of VA units in EVA was added % sodium hydroxide (catalyst) / alcohol solution, alcoholysis / saponification reaction at 65°C for 3h, forming a vinyl copolymer / methanol solution (abbreviation: component A / methanol solution) containing hydroxyl and ester groups in side groups, wherein The ethylene content in component A is 37 mol%, the vinyl acetate structural unit content is 0.6 mol%, and the vinyl alcohol structural unit content is 62.4 mol%.

[0059] The preparation process of the vinyl polymer nanocomposite material containing polar side groups is the same as that in Example 1, except that the above-mentioned synthesized vinyl copolymer alcohol solution containing hydroxyl and ester groups in the side groups is used to replace DK2 with ten Octyl hydrox...

Embodiment 3

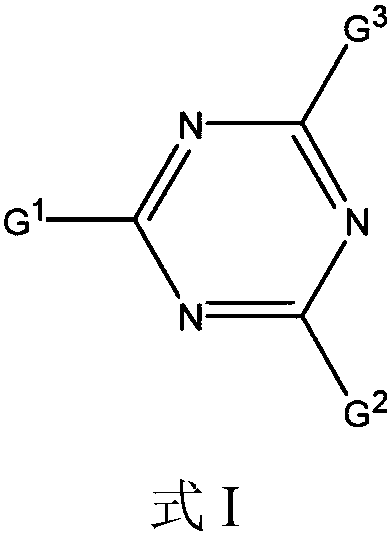

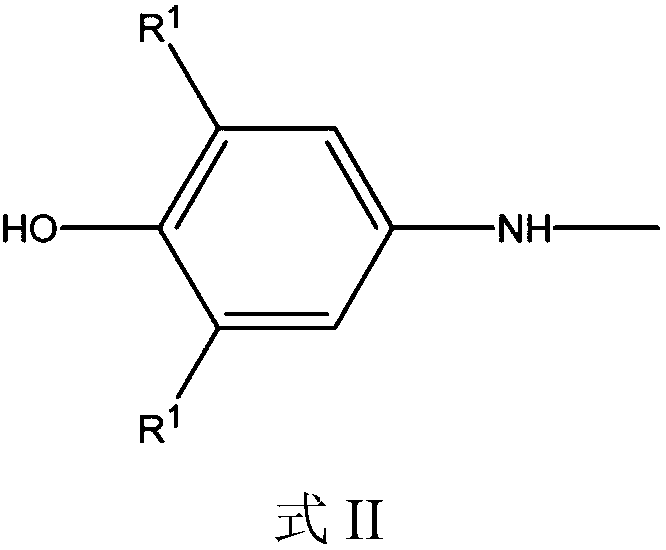

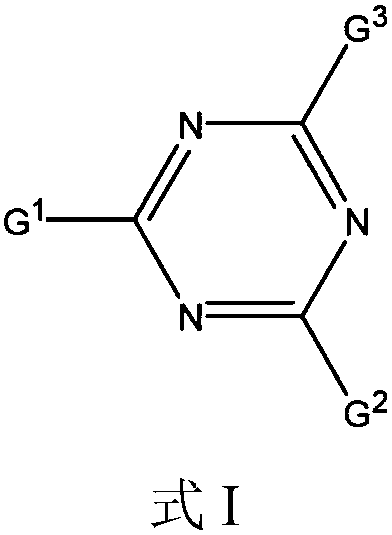

[0064] The preparation process of the vinyl polymer nanocomposite containing polar side groups is the same as in Example 1, except that 4-[(4,6-dioctylthio-1,3,5-triazine-2 -yl)amino]-2,6-di-tert-butylphenol (component C) was first mixed with component A / methanol for 45min, and then mixed with stearyl hydroxyammonium chloride modified montmorillonite (component B , DK0) mixed for 10min. Aftertreatment method is the same as embodiment 1.

[0065] The obtained nanocomposite material takes component A as 100%, the content of component B as 5%, and the content of component C as 0.1%.

[0066] The storage modulus of the prepared nanocomposite at 25°C is 3349MPa, which is 1.1 times higher than that of component A (comparative example 1, 1587MPa) without any additives; Decomposition temperature T d is 267°C, and component A without any additives (T d =256°C) compared to T d Increased by 11°C.

[0067] The prepared nanocomposite melting point is 173°C, and the melting enthalpy i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Oxygen permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com