Barrier polyester and preparation method thereof

A barrier and polyester technology, applied in the field of barrier polyester and its preparation, can solve the problems of short processing flow, affecting the physical and chemical properties of PET, low energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

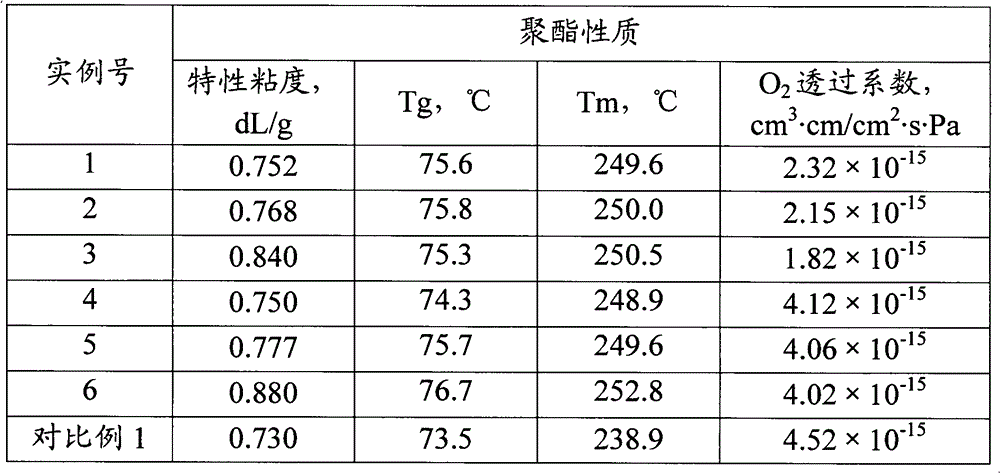

Examples

preparation example Construction

[0016] The preparation method of the polyester provided by the present invention includes mixing terephthalic acid, ethylene glycol and a barrier comonomer, first performing an esterification reaction in the presence of a catalyst, and then performing a polycondensation reaction after heating up.

[0017] In the above method, the molar ratio of carboxyl group and hydroxyl group in terephthalic acid, ethylene glycol and barrier comonomer, that is, the molar ratio of total carboxyl group and total hydroxyl group contained in the reactant is 1: 1.0~1.8, preferably 1: 1.1~ 1.5.

[0018] The molar percentage of hydroxyl and carboxyl groups (the sum of the two) provided by the barrier comonomer to the total hydroxyl and total carboxyl groups (the sum of the two) of the reactant is 0.5-10 mol%, preferably 0.5-5 mol%.

[0019] The preparation method of the barrier polyester provided by the present invention is divided into two steps. The first step is an esterification reaction betwee...

example 1

[0025] Add 415.0g (2.50mol) of terephthalic acid, 184.1g (2.97mol) of ethylene glycol, 4.44g (0.03mol) of 3,5-dihydroxyhexanoic acid and 0.2g of catalyst antimony acetate into the autoclave, and use nitrogen Replace the gas in the kettle twice. The esterification reaction was carried out at 230° C. for 2 hours under a pressure of 0.1 MPa and stirring. The temperature was raised to 280°C, and a polycondensation reaction was carried out under reduced pressure for 2 hours. The polyester product was collected, and its properties were shown in Table 1, and the polyester contained 0.8% by mass of 3,5-dihydroxyhexanoic acid.

example 2

[0027] 415.0g (2.50mol) of terephthalic acid, 180.4g (2.91mol) of ethylene glycol, 13.32g (0.09mol) of 3,5-dihydroxyhexanoic acid and 0.2g of catalyst antimony acetate were added to the autoclave, and nitrogen was added to the reactor. Replace the gas in the kettle twice. The esterification reaction was carried out at 230° C. for 1 hour under a pressure of 0.1 MPa and stirring. The temperature was raised to 280°C, and the polycondensation reaction was carried out under reduced pressure for 1 hour. The polyester product was collected, and its properties are shown in Table 1. The polyester contained 2.2% by mass of 3,5-dihydroxyhexanoic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com