Air-isolating type environment-friendly composite material as well as preparation method and application thereof

A composite material and environmental protection technology, applied in the field of degradable plastics, can solve the problems of poor gas barrier performance and inability to meet the preservation function, etc., and achieve the effects of good environmental protection, good mechanical performance and high degree of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

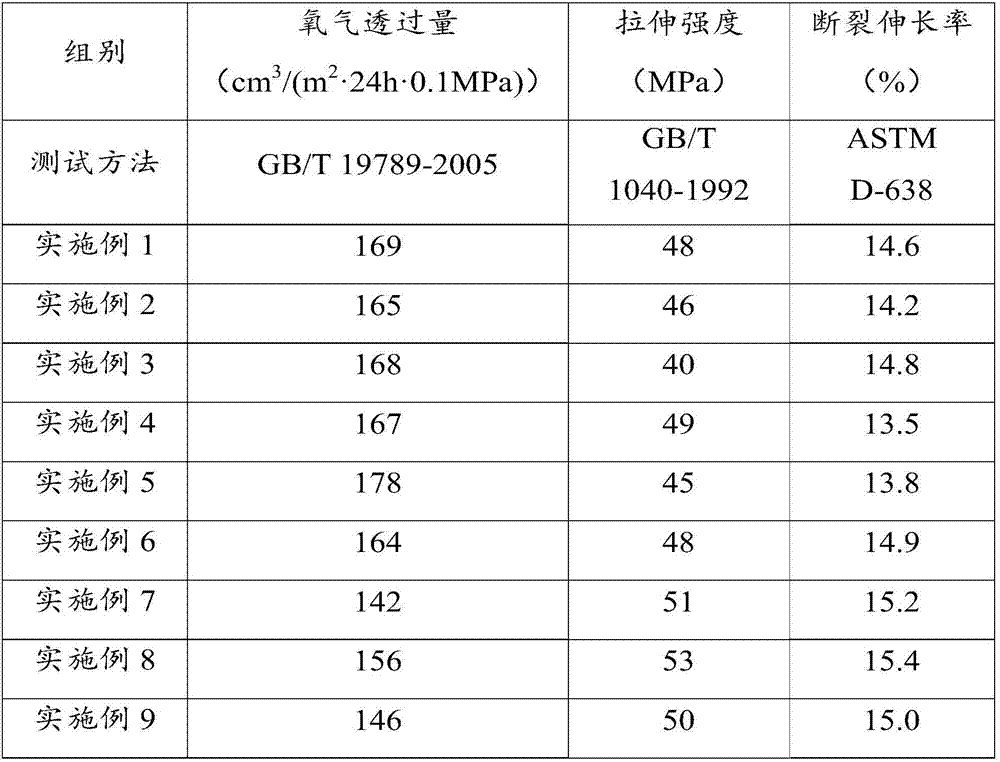

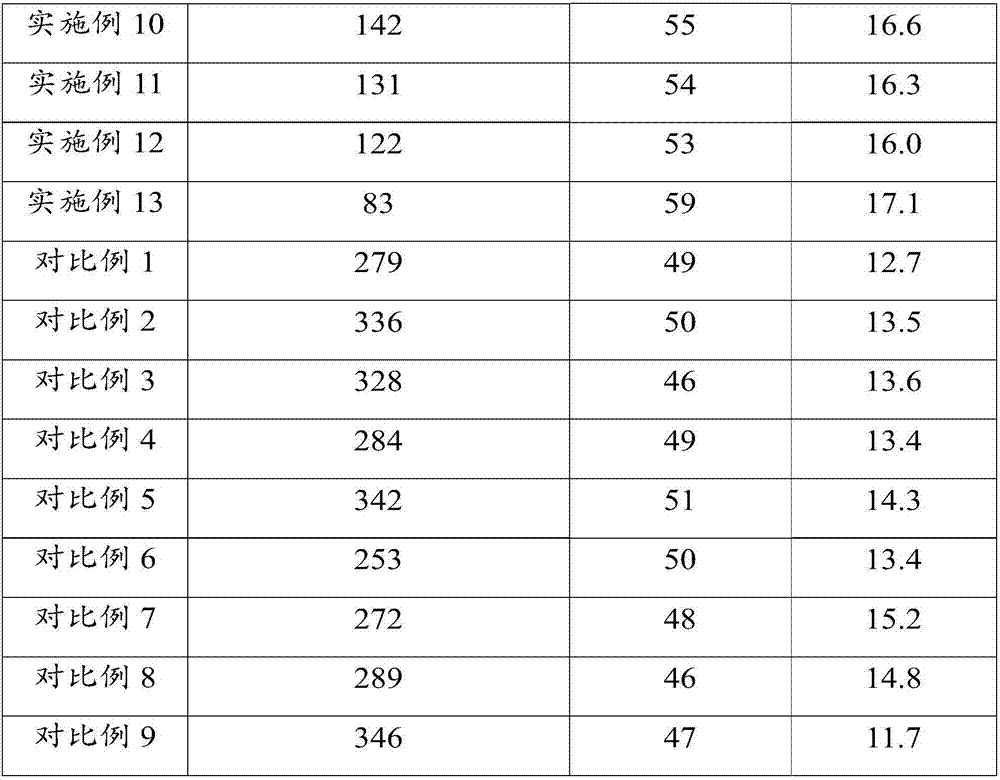

Examples

preparation example Construction

[0056] In a second aspect, the present invention provides a method for preparing the above gas-insulating and environment-friendly composite material, comprising the following steps:

[0057] (a) PLA, nano-titanium nitride, anti-hydrolysis stabilizer and chain extender are mixed uniformly and granulated to obtain PLA / nano-titanium nitride masterbatch;

[0058] (b) PLA / nano-titanium nitride masterbatch, PLA, PBAT, polypropylene carbonate, filler, thermoplastic elastomer, lubricant and chain extender are mixed uniformly and then granulated to obtain the gas-insulated and environmentally friendly composite material.

[0059] The above preparation method has simple process, easy operation, high controllability, and is suitable for mass production. The gas-insulating and environmentally friendly composite material obtained by this method has the advantages of good environmental protection, high gas barrier rate, good thermal stability and good mechanical properties. .

[0060] In...

Embodiment 1

[0068] A gas-insulating and environmentally friendly composite material, mainly prepared from the following raw materials in parts by weight: 20 parts of PLA, 20 parts of PBAT, 5 parts of polypropylene carbonate, 1 part of PLA / nano-titanium nitride masterbatch, 3 parts of silicon dioxide 1 part of syndiotactic l,2-polybutadiene, 0.5 part of erucamide and 1 part of chain extender;

[0069] The PLA / nano-titanium nitride masterbatch is mainly prepared from the following raw materials in parts by weight: 80 parts of PLA, 0.3 part of nano-titanium nitride, 0.3 part of anti-hydrolysis stabilizer and 0.5 part of chain extender.

Embodiment 2

[0071] A gas-insulating and environmentally friendly composite material, mainly prepared from the following raw materials in parts by weight: 35 parts of PLA, 28 parts of PBAT, 8 parts of polypropylene carbonate, 3 parts of PLA / nano-titanium nitride masterbatch, and 7 parts of talcum powder , 2 parts of syndiotactic l,2-polybutadiene, 0.6 parts of EBS and 1.4 parts of chain extender;

[0072] The PLA / nano-titanium nitride masterbatch is mainly prepared from the following raw materials in parts by weight: 88 parts of PLA, 0.3 part of nano-titanium nitride, 0.3 part of anti-hydrolysis stabilizer and 0.8 part of chain extender.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com