Method for preparing edible preservative film of fresh fruit

A technology for fresh-keeping film and fruit, which is applied in the fields of fruit and vegetable preservation, food preservation, and protection of fruits/vegetables with a coating protective layer. Popularization and application, good gas and moisture resistance, and the effect of improving the storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

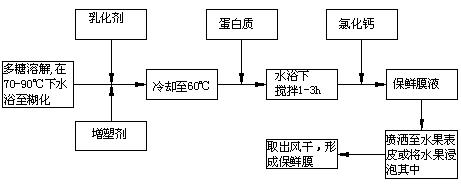

[0023] A kind of preparation method of edible fresh-keeping film of fresh fruit, comprises the following steps:

[0024] (1) Determine the polysaccharide, protein, emulsifier, plasticizer, calcium chloride, etc. in the plastic wrap solution, and dissolve the protein, polysaccharide, emulsifier, plasticizer, calcium chloride, etc. in water according to a certain ratio, To prepare the edible plastic wrap solution:

[0025] Step 1: Dissolve the polysaccharide in water, the amount of polysaccharide added is 1-5%, in a water bath at 70-90°C until it is completely gelatinized;

[0026] The second step: adding emulsifier and plasticizer, the mass percentage of emulsifier added is 0.5-2%, and the amount of plasticizer added is 1-3%;

[0027] Step 3: After cooling to 60°C, add 1-5% protein slowly under stirring;

[0028] Step 4: Stir in a water bath at 60°C for 1-3 hours;

[0029] Step 5: Add calcium chloride in an amount of 0.1-1%;

[0030] Step 6: Cool to room temperature to obta...

Embodiment 1

[0036] The polysaccharide in the edible preservative film liquid is corn starch, the protein is soybean protein isolate, the emulsifier is sucrose fatty acid ester, the plasticizer is glycerin, and the calcium chloride is anhydrous calcium chloride. Dissolve cornstarch in water, add 5%, put it in a water bath at 80°C until it is completely gelatinized, add 2% glycerin and 1% sucrose fatty acid ester, then cool to 60°C and slowly add 2% of it while stirring Soybean protein isolate, stirred in a water bath at 60°C for 2 hours, anhydrous calcium chloride was added in an amount of 0.5%, cooled to room temperature to obtain a preservative film solution. Soak the tomatoes in the plastic wrap solution for 3 minutes, take them out, and quickly dry them in cold air, and measure the changes in weight loss rate, hardness, total sugar, and total acid during storage.

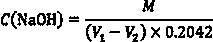

[0037] (1)

[0038] W 0 - initial weight of tomato, g

[0039] W T —...

Embodiment 2

[0069] The polysaccharide in the preservative film liquid is corn starch, the protein is soybean protein isolate, the emulsifier is sucrose fatty acid ester, the plasticizer is glycerin, and the calcium chloride is anhydrous calcium chloride. Dissolve cornstarch in water, add 3% in water bath at 80°C until completely gelatinized, add 4% glycerin and 1% sucrose fatty acid ester, then cool to 60°C and slowly add 2% soybean under stirring Separate the protein, stir in a water bath at 60°C for 2 hours, add anhydrous calcium chloride in an amount of 0.5%, and cool to room temperature to obtain a preservative film solution. Soak the tomatoes in the plastic wrap solution for 3 minutes, take them out, and quickly dry them in cold air, and measure the changes in weight loss rate, hardness, total sugar, and total acid during storage.

[0070] (1)

[0071] W 0 - initial weight of tomato, g

[0072] W T ——the weight of tomato after T days, g

[0073] (2) Changes in the hardness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com