Flaky nanometer molybdenum disulfide material, nanometer composite metal anticorrosive coating material and preparation method of flaky nanometer molybdenum disulfide material and nanometer composite metal anticorrosive coating material

A technology of nano-molybdenum disulfide and molybdenum disulfide, which is applied in the direction of anti-corrosion coatings, nanotechnology for materials and surface science, molybdenum sulfide, etc., and can solve the problems of small preparation scale, increased interlayer spacing of molybdenum disulfide, and poor repeatability and other problems, to achieve the effect of simple preparation method, good dispersibility and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

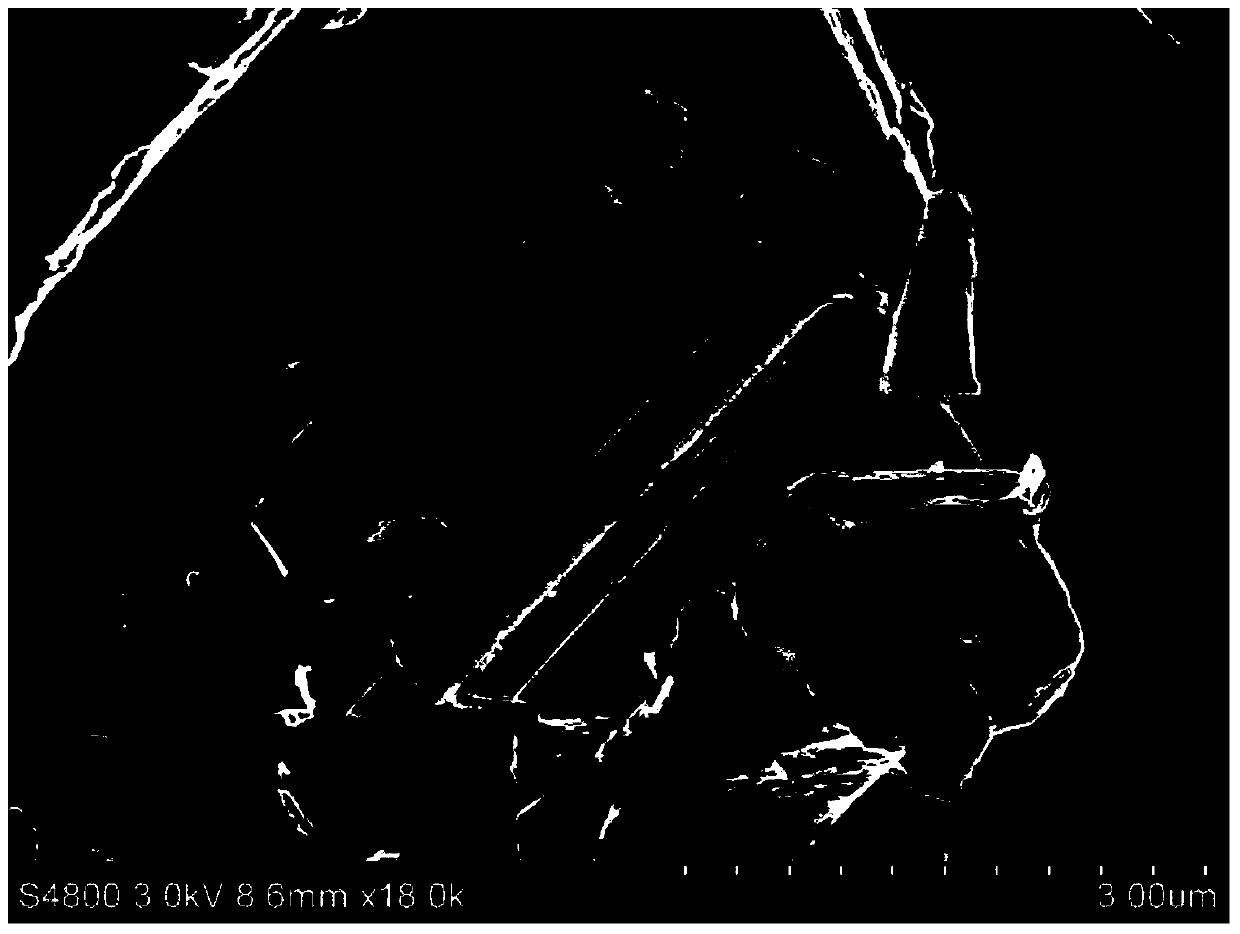

[0040] Add 2 grams of nitric acid into a 100mL round-bottomed flask containing 6 grams of hydrochloric acid, add 0.2 gram of molybdenum disulfide powder, install a straight condenser tube in the round-bottomed flask, and put on a tail gas absorption device, and drain the tail gas with water Absorption, to avoid exhausting the tail gas directly into the air, use an oil bath to heat, raise the oil bath to 110°C, and keep it for 30 minutes. After the reaction is completed, add 30mL deionized water to dilute the reaction solution, and then use centrifugation to separate the product Separated and washed three times with deionized water and once with isopropanol, finally the resulting product was dispersed in 2 g of isopropanol. The SEM figure, TEM figure, HTEM figure, lattice electron diffraction figure of the flaky nano-molybdenum disulfide prepared by the present embodiment and the following examples are respectively as follows Figure 2-5 shown. Compare the SEM images of the mo...

Embodiment 2

[0042] Add 2 grams of nitric acid into a 100mL round-bottomed flask containing 6 grams of hydrochloric acid, add 0.2 gram of molybdenum disulfide powder, install a straight condenser tube in the round-bottomed flask, and put on a tail gas absorption device, and drain the tail gas with water Absorption, to avoid exhausting the tail gas directly into the air, place the reaction bottle in an ultrasonic generator, and perform ultrasonication. The temperature of the water bath is set to 50°C, and ultrasonication is performed for 20 minutes. The product was then separated by centrifugation, washed three times with deionized water and once with isopropanol, and finally the obtained product was dispersed in 2 g of isopropanol.

Embodiment 3

[0044] Add 3 grams of nitric acid into a 100mL round-bottomed flask containing 6 grams of hydrochloric acid, add 0.2 gram of molybdenum disulfide powder, install a straight condenser tube in the round-bottomed flask, and put a tail gas absorption device on it. Absorption, to avoid exhausting the tail gas directly into the air, use an oil bath to heat, raise the oil bath to 110°C, and keep it for 30 minutes. After the reaction is completed, add 30mL deionized water to dilute the reaction solution, and then use centrifugation to separate the product Separated and washed three times with deionized water and once with isopropanol, finally the resulting product was dispersed in 2 g of isopropanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com