A kind of preparation method of dendrimer modified magnetic nanocrystalline cellulose surface imprinted polymer

A technology of nanocrystalline cellulose and dendrimers, which is applied in the field of food science, can solve the problems of irregular polymer shape, slow mass transfer speed, and few effective binding sites, and achieve rapid separation, increase adsorption capacity, and good The effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

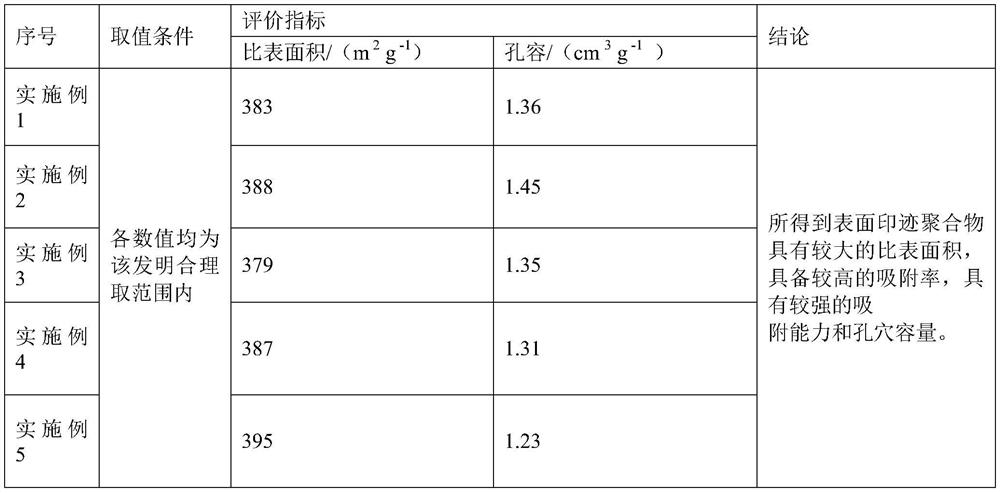

Examples

Embodiment 1

[0033] A method for preparing dendrimer-modified magnetic nanocrystalline cellulose surface imprinted polymers, the specific preparation steps are as follows:

[0034] (1) Activated magnetic Fe 3 o 4 Nanoparticles: Add 3-propyltrimethoxysilane to deionized water, raise the temperature to 40°C, add magnetic Fe 3 o 4 Nanoparticles, stirring and constant temperature reaction for 35min, magnetic separation, and drying to obtain alkylated magnetic Fe 3 o 4 nanoparticles;

[0035] (2) Synthesis of magnetic nanocrystalline cellulose: nanocrystalline cellulose and methylene succinic acid are added in the aqueous solution of acetic acid, stirred and dissolved to obtain a mixed solution, the mass ratio of nanocrystalline cellulose and methylene succinic acid is 1 :5; Alkylated magnetic Fe 3 o 4 Add the nanoparticles into the mixed solution, raise the temperature to 48°C, add the initiator diisopropyl peroxydicarbonate, react at a constant temperature for 43 minutes, and magnetica...

Embodiment 2

[0039] The difference from Example 1 is that a method for preparing a dendrimer-modified magnetic nanocrystalline cellulose surface imprinted polymer, the specific preparation steps are as follows:

[0040] (1) Activated magnetic Fe 3 o 4 Nanoparticles: Add 3-propyltrimethoxysilane to deionized water, heat up to 35°C, add magnetic Fe 3 o 4 Nanoparticles, stirred and reacted at constant temperature for 30-40min, magnetically separated, and dried to obtain alkylated magnetic Fe 3 o 4 nanoparticles;

[0041] (2) Synthesis of magnetic nanocrystalline cellulose: nanocrystalline cellulose and methylene succinic acid are added in the aqueous solution of acetic acid, stirred and dissolved to obtain a mixed solution, the mass ratio of nanocrystalline cellulose and methylene succinic acid is 1 :4; Alkylated magnetic Fe 3 o 4 Add the nanoparticles into the mixed solution, raise the temperature to 45°C, add the initiator diisopropyl peroxydicarbonate, react at a constant temperatur...

Embodiment 3

[0045] The difference from Example 1 is that a method for preparing a dendrimer-modified magnetic nanocrystalline cellulose surface imprinted polymer, the specific preparation steps are as follows:

[0046] (1) Activated magnetic Fe 3 o 4 Nanoparticles: Add 3-propyltrimethoxysilane to deionized water, heat up to 45°C, add magnetic Fe 3 o 4 Nanoparticles, stirred and reacted at constant temperature for 40 minutes, magnetically separated, and dried to obtain alkylated magnetic Fe 3 o 4 nanoparticles;

[0047] (2) Synthesis of magnetic nanocrystalline cellulose: nanocrystalline cellulose and methylene succinic acid are added in the aqueous solution of acetic acid, stirred and dissolved to obtain a mixed solution, the mass ratio of nanocrystalline cellulose and methylene succinic acid is 1 :6; Alkylated magnetic Fe 3 o 4 Add the nanoparticles into the mixed solution, raise the temperature to 50°C, add the initiator diisopropyl peroxydicarbonate, react at a constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com