Cobalt-based fischer-tropsch synthesis catalyst and preparation method and application

A Fischer-Tropsch synthesis and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as high olefin content in products, low diesel selectivity, and large airgel pore size , to achieve high diesel selectivity, improved impregnation, and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

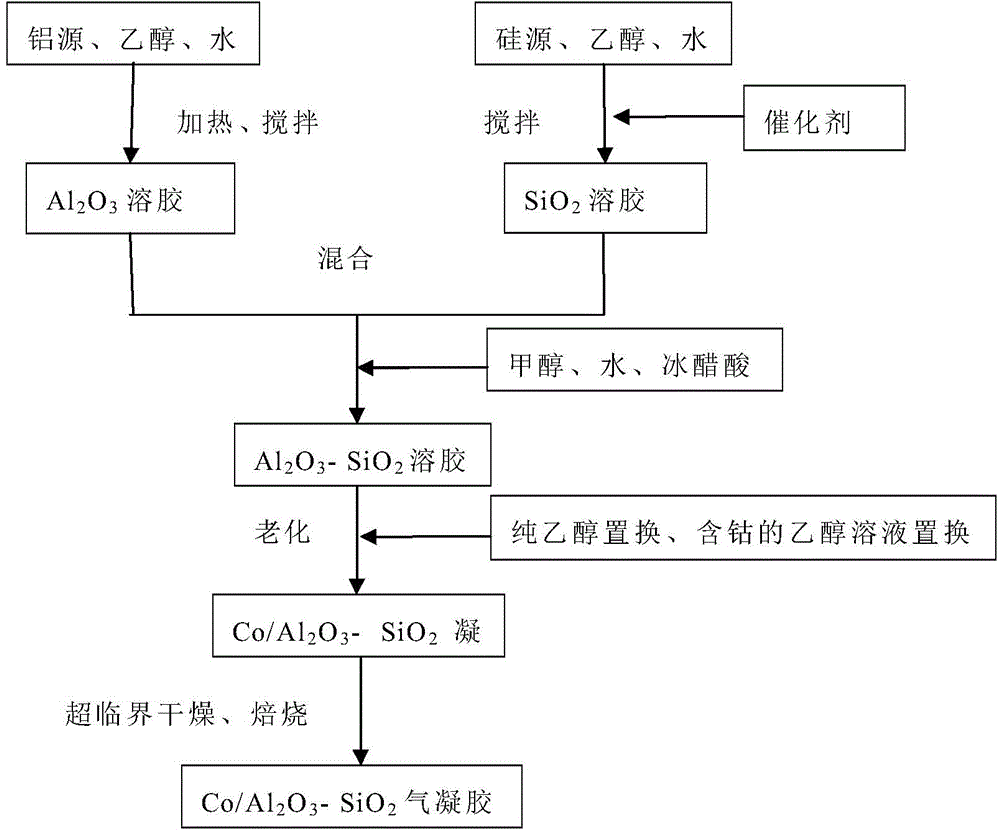

Method used

Image

Examples

Embodiment 1

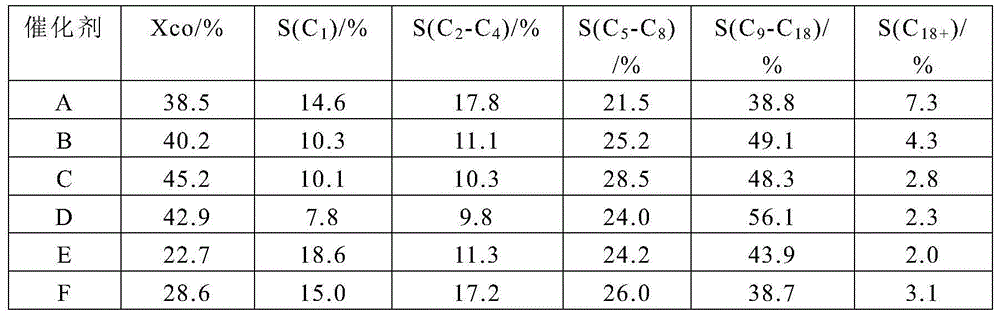

[0030] Catalyst A consists of active component Co, carrier Al 2 o3 -SiO 2 Composite airgel composition. Co content is 2%, Al 2 o 3 -SiO 2 The content is 98%. The preparation method of catalyst A is as follows:

[0031] 1) Weigh 1.7g of deionized water and add it to 32.03g of aluminum isopropoxide, transfer it to 28.89g of ethanol after mixing, stir at a constant temperature of 45°C for 60 minutes, let it stand to cool to room temperature, and obtain Al 2 o 3 sol, and store it in the refrigerator.

[0032] 2) Weigh 25.38g of methyl orthosilicate, 30.73g of ethanol and 12.02g of deionized water and mix evenly, then add ammonia water to adjust the pH value of the solution to 8, stir for 20 minutes, and let stand until the gel is formed to obtain SiO 2 Sol.

[0033] 3) Weigh 1.18gSiO2 2 Sol was added to 8.02gAl 2 o 3 In the sol, after mixing and stirring evenly, add the mixed solution of 2.76g glacial acetic acid, methanol and water, wherein the volume ratio of glacial...

Embodiment 2

[0038] Catalyst B consists of active component Co, carrier Al 2 o 3 -SiO 2 Composite airgel composition. Co content is 5%, Al 2 o 3 -SiO 2 The content is 95%. The preparation method of catalyst B is as follows:

[0039] 1) Weigh 1.7g of deionized water and add it to 38.62g of aluminum sec-butoxide, transfer it to 72.22g of ethanol after mixing, stir at a constant temperature of 55°C for 55 minutes, let it stand to cool to room temperature, and obtain Al 2 o 3 sol, and store it in the refrigerator.

[0040] 2) Weigh 34.74g tetraethyl orthosilicate, 46.09g ethanol and 15.03g deionized water and mix evenly, then add ammonia water to adjust the pH value of the solution to 9, stir for 25 minutes, let it stand until the gel is formed, and obtain SiO 2 Sol.

[0041] 3) Weigh 4.71gSiO2 2 Sol was added to 7.44gAl 2 o 3 In the sol, after mixing and stirring evenly, add a mixed solution of 1.82g glacial acetic acid, methanol and water, wherein the volume ratio of glacial ace...

Embodiment 3

[0046] Catalyst C consists of active component Co, carrier Al 2 o 3 -SiO 2 Composite airgel composition. Co content is 10%, Al 2 o 3 -SiO 2 The content is 90%. The preparation method of catalyst C is as follows:

[0047] 1) Weigh 1.7g of deionized water and add it to 58.88g of aluminum nitrate nonahydrate, transfer it to 115.56g of ethanol after mixing, stir at a constant temperature of 65°C for 40 minutes, let it stand to cool to room temperature, and obtain Al 2 o 3 sol, and store it in the refrigerator.

[0048] 2) Weigh 34.74g of tetraethyl orthosilicate, 61.46g of ethanol and 18.036g of deionized water and mix evenly, then add ammonia water to adjust the pH value of the solution to 8, stir for 30 minutes, and let stand until the gel is formed to obtain SiO 2 Sol.

[0049] 3) Weigh 9.42gSiO2 2 Sol was added to 8.09gAl 2 o 3 In the sol, after mixing and stirring evenly, add a mixed solution of 0.18g glacial acetic acid, methanol and water, wherein the volume ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com