Three-dimensional combined-duct antimony-doped tin dioxide electrode and preparation method and application thereof

A tin dioxide, three-dimensional composite technology, applied in chemical instruments and methods, oxidized water/sewage treatment, electrochemical water/sewage treatment, etc. Problems such as limited improvement of catalytic oxidation ability, etc., to achieve the effect of increased contact, cheap raw materials, and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

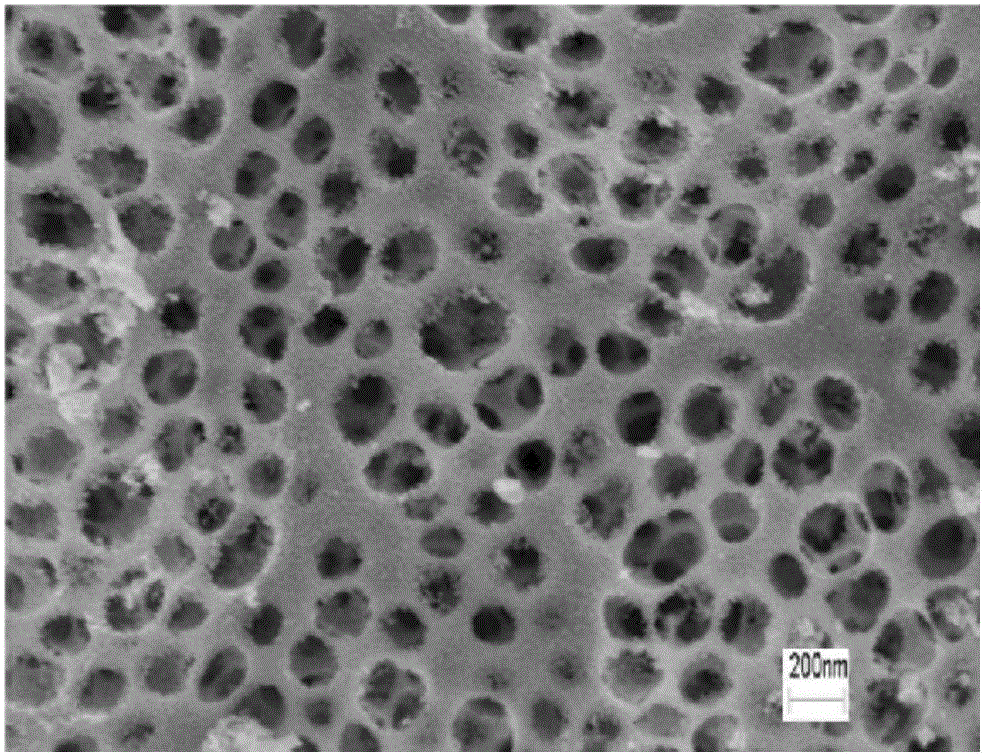

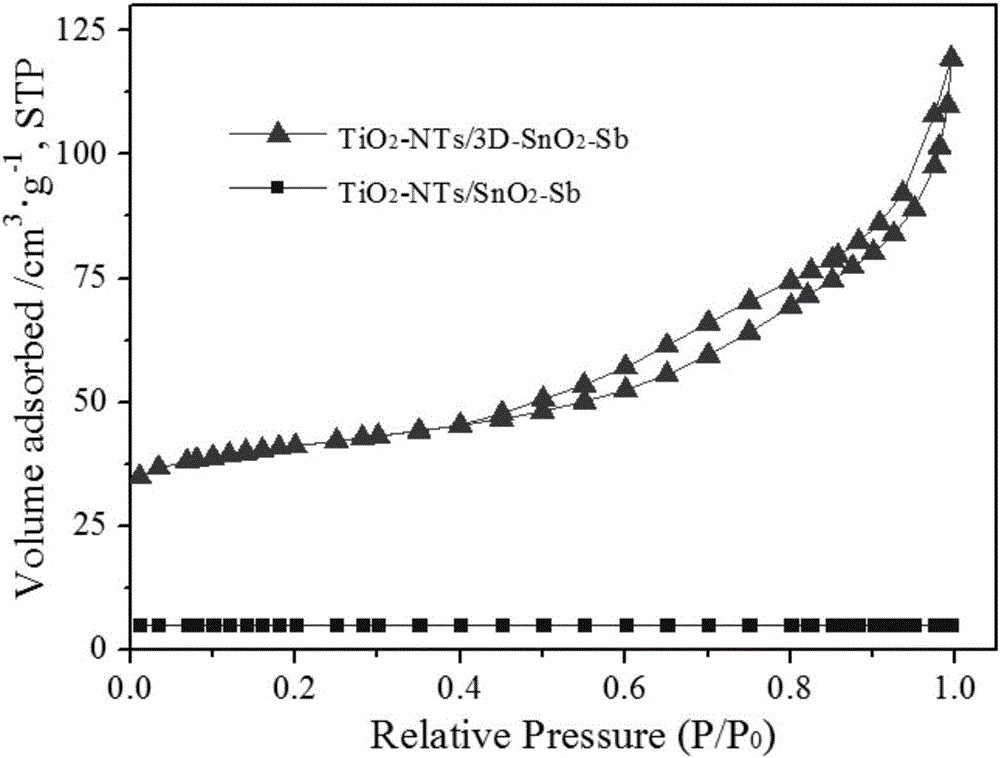

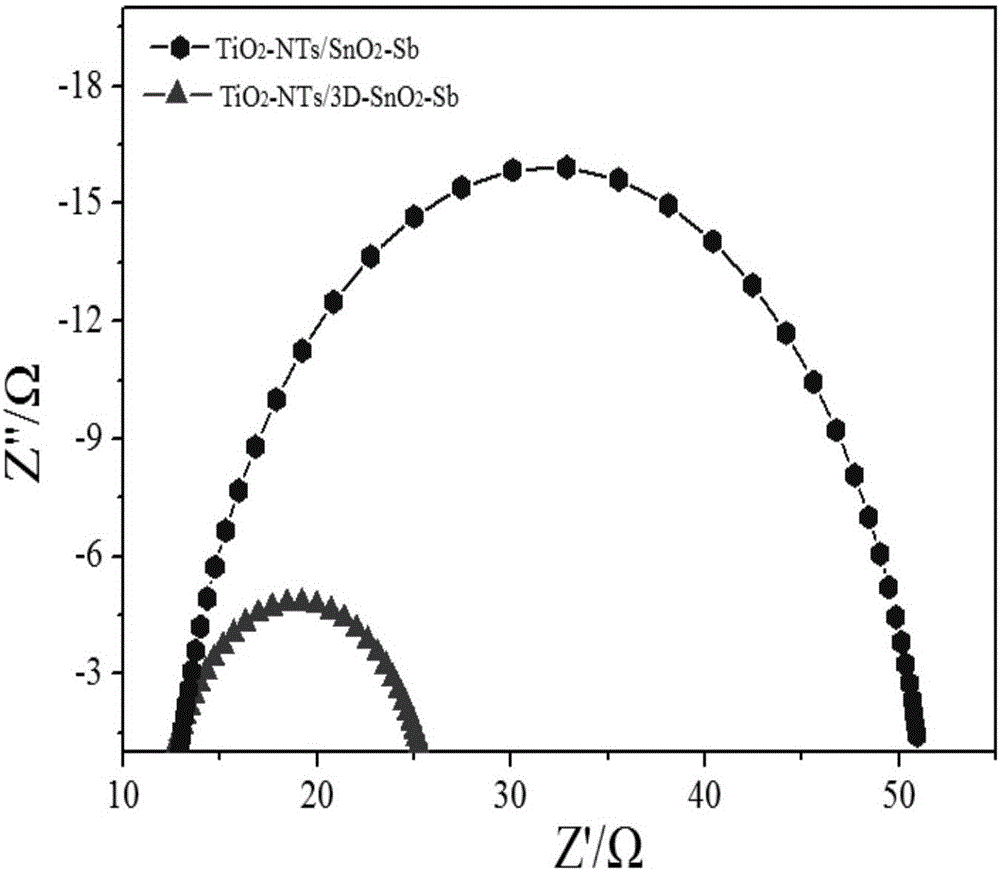

[0024] A three-dimensional composite channel antimony-doped tin dioxide electrode, the specific preparation is as follows (1) Clean the surface of the titanium material as the bottom layer, and then add 0.05mol / L hydrogen fluoride, 0.05mol / L potassium fluoride and 0.1mol / L Carry out anodic oxidation in a mixed solution of L sulfuric acid for 60 minutes, the operating voltage is 25V, take out and wash, heat and roast at 500°C for 4 hours, control the heating rate to 2°C / min, and obtain the titanium dioxide nanotube intermediate layer. (2) The prepared titanium-based titania nanotubes were immersed in 0.2% polymethyl methacrylate (PMMA) microsphere suspension, and dried in an oven at 45°C to obtain titanium-based titania nanotubes assembled with PMMA templates . (3) The titanium-based titanium dioxide nanotubes assembled with PMMA templates were impregnated with 0.5mol / L tin tetrachloride, 0.03mol / L antimony trichloride, 0.05mol / L citric acid and 4mmol / L triblock copolymer Imme...

Embodiment example 2

[0026] A three-dimensional composite channel antimony-doped tin dioxide electrode, the specific preparation is as follows (1) Clean the surface of the titanium material as the bottom layer, and then add 0.1mol / L hydrogen fluoride, 0.01mol / L sodium fluoride and 0.05mol / L Carry out anodic oxidation in a mixed solution of L sulfuric acid for 30 minutes, the operating voltage is 20V, take out and wash, heat and roast at 450°C for 3 hours, and control the heating rate to 1°C / min to obtain the titanium dioxide nanotube intermediate layer. (2) The prepared titanium-based titania nanotubes were immersed in 0.05% polymethyl methacrylate (PMMA) microsphere suspension, and dried in an oven at 40°C to obtain titanium-based titania nanotubes assembled with PMMA templates . (3) The titanium-based titanium dioxide nanotubes assembled with PMMA templates were impregnated with 0.2mol / L tin tetrachloride, 0.01mol / L antimony trichloride, 0.02mol / L citric acid and 1mmol / L triblock copolymer Imme...

Embodiment example 3

[0028]A three-dimensional composite channel antimony-doped tin dioxide electrode, the specific preparation is as follows (1) Clean the surface of the titanium material as the bottom layer, and then add 0.01mol / L hydrogen fluoride, 0.1mol / L sodium fluoride and 0.15mol / L Carry out anodic oxidation in a mixed solution of L hydrochloric acid for 90 minutes, the operating voltage is 30V, take out and wash, heat and roast at 550°C for 5 hours, and control the heating rate to 3°C / min to obtain the titanium dioxide nanotube intermediate layer. (2) The prepared titanium-based titania nanotubes were immersed in 0.5% polystyrene (PS) microsphere suspension, and dried in an oven at 50°C to obtain titanium-based titania nanotubes assembled with PS templates. (3) The titanium-based titanium dioxide nanotubes assembled with PMMA templates were impregnated with 0.8mol / L tin tetrachloride, 0.05mol / L antimony trichloride, 0.08mol / L citric acid and 8mmol / L triblock copolymer Immerse in the precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com