Preparation of hydrodeoxygenation isomerization catalyst and application thereof in preparation of diesel oil from illegal cooking oil

A deoxygenation catalyst, hydrodeoxygenation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, preparation of liquid hydrocarbon mixtures, etc. Catalyst deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061]Example 1 Preparation of HUSY-1 molecular sieve by hydrothermal aging treatment of Y molecular sieve

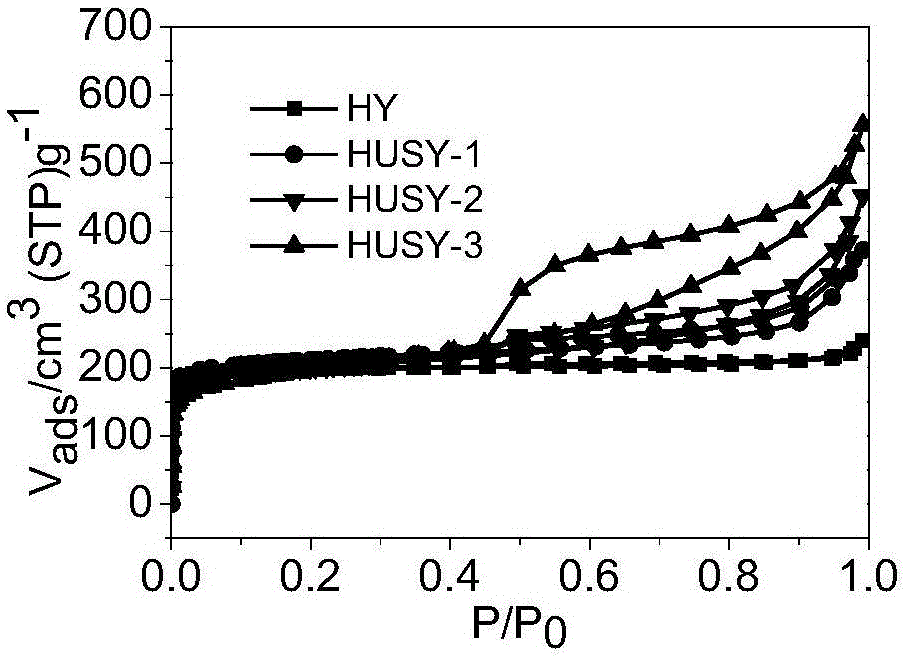

[0062] Air was introduced at a flow rate of 2L / min, and 2gY molecular sieve was raised from room temperature to 750°C in the quartz tube, and then 20mL / min water vapor was introduced, and after 4 hours of treatment, it was cooled to room temperature; the parent Y molecular sieve and hydrothermal aging (HUSY-1 ) specific surface and pore volume data (see Table 1), adsorption-desorption isotherm (see figure 1 ). From the data in Table 1, it can be seen that the carrier after steam aging treatment has a higher outer surface (from 17 to 45m 2 g -1 ) and larger mesopore volume (from 0.07 to 0.11cm 3 g -1 ). figure 1 It is also shown that water vapor treatment will make molecular sieve materials have more mesopore specific surface area and volume.

[0063] In this embodiment, when the reaction temperature is 350-850°C, the reaction time is 0.5-6h, and the water vapor fl...

Embodiment 2

[0064] Example 2 Acid dealumination of HUSY-1 molecular sieve to prepare HUSY-2 molecular sieve

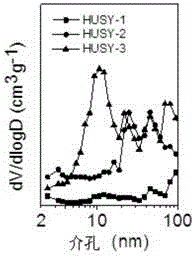

[0065] Feed 2g of HUSY-1 molecular sieve and nitric acid solution at a ratio of 2 / 70g / mL, heat in an oil bath at 90°C for 6 hours, and after a full reaction, filter, wash, dry, and roast to obtain acid dealuminated molecular sieve HUSY-2; The specific surface and pore volume data of the obtained HUSY-2 molecular sieve and the HUSY-1 obtained by hydrothermal aging are shown in Table 1, and the outer surface (from 45 to 105m 2 g -1 ) and larger mesopore volume (from 0.11 to 0.29cm 3 g -1 ); see the pore size distribution of HUSY-1 and HUSY-2 figure 2 . figure 2 It shows that the molecular sieve after acid dealumination has a larger mesopore diameter, and Table 1 shows that the treated carrier has a higher external surface area and a larger mesopore volume.

[0066] In this embodiment, when the acid is hydrochloric acid, the acid concentration is 0.1-2mol / L, the pickling time ...

Embodiment 3

[0069] Example 3 Alkali desiliconization treatment of HUSY-2 molecular sieve to prepare HUSY-3 molecular sieve

[0070] Feed the mixed solution of HUSY-2 molecular sieve, sodium hydroxide and tetraethylammonium hydroxide at a ratio of 3 / 100g / mL, the total alkali concentration is 0.6mol / L, and the molar ratio of alkali to protective agent is 1.2:1, 90 Heating in an oil bath at ℃ for 3 hours, after fully reacting, filtering, washing, drying, roasting and three times ammonia exchange to obtain alkali desiliconization molecular sieve HUSY-3; HUSY-3 molecular sieve obtained by alkali desiliconization and acid dealumination The specific surface and pore volume data of HUSY-2 are shown in Table 1, the outer surface (increased from 105 to 150m 2 g -1 ) and larger mesopore volume (from 0.29 to 0.42cm 3 g -1 ); see the pore size distribution of HUSY-2 and HUSY-3 figure 2 . figure 2 It shows that the molecular sieve after alkali desilication has mesopores with narrower pore size d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| micropore | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com