High-energy-density Li-air battery air electrode, and battery and making method thereof

A lithium-air battery and air electrode technology, applied in the field of electrochemistry, can solve the problems of high thermal conductivity, poor cycle performance, low discharge capacity, etc., achieve high chemical performance and safety performance, and increase the effect of catalytic reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

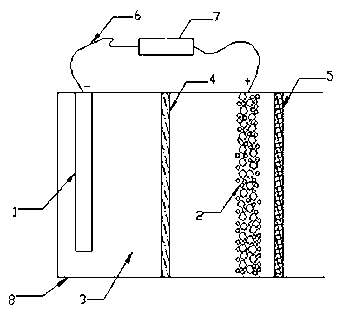

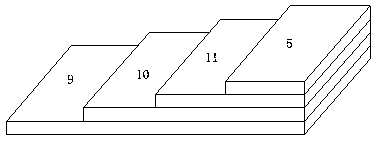

Image

Examples

Embodiment 1

[0037] The preparation method of nano-graphene used in the present invention is as follows, in addition, nano-graphene prepared by other methods is also suitable for the present invention. SiO used in the present invention 2 Aerogels are commercially available.

[0038] S1. Nanographene and SiO 2 Preparation of airgel composite dual-porous system material:

[0039] S11. Add concentrated sulfuric acid (230ml, 98%) and sodium nitrate 5g in the 1000ml beaker, mechanically stir in ice-water bath for 15 minutes to obtain mixed acid;

[0040] S12. Take 10g of natural graphite or artificial graphite and add it, after stirring for 10 minutes, gradually add 30g of potassium permanganate powder, the addition speed is 5g / 5min, control the reaction temperature not to exceed 20°C, and then place the beaker at 35°C In a constant temperature water bath, stir evenly.

[0041] S13. After constant temperature reaction for 2 hours, add 500ml of deionized water, control the reaction tempe...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is: the lithium electrode material is a lithium alloy; the catalyst is: MnO 2 and Pt; the binder is polyethylene; the non-aqueous electrolyte is: 30% LiSO 3 CF 3 And 70%PC / TFP mixed solution; Diaphragm is: polyethylene nanofiltration membrane; Other modes are identical with embodiment 1.

[0061] The energy density of the battery described in this embodiment is 10000Wh / kg (calculated by carbon), the capacity is up to 8412.3mAh / g (calculated by carbon), and it can be charged and discharged more than 100 times. Energy density and capacity remain largely unchanged.

Embodiment 3

[0063] The difference between this embodiment and 1 is: the lithium electrode material is a lithium alloy: the catalyst is: Mn 2 o 3 and Pt; the binder is polypropylene; the non-aqueous electrolyte is: 30% LiSO 3 CF 3 And 70%PC / TTFP; Diaphragm is: polypropylene nanofiltration diaphragm; Other modes are identical with embodiment 1.

[0064] The energy density of the battery described in this embodiment is 10000Wh / kg (calculated by carbon), the capacity is up to 8133.3mAh / g (calculated by carbon), and it can be charged and discharged more than 100 times. Energy density and capacity remain largely unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com