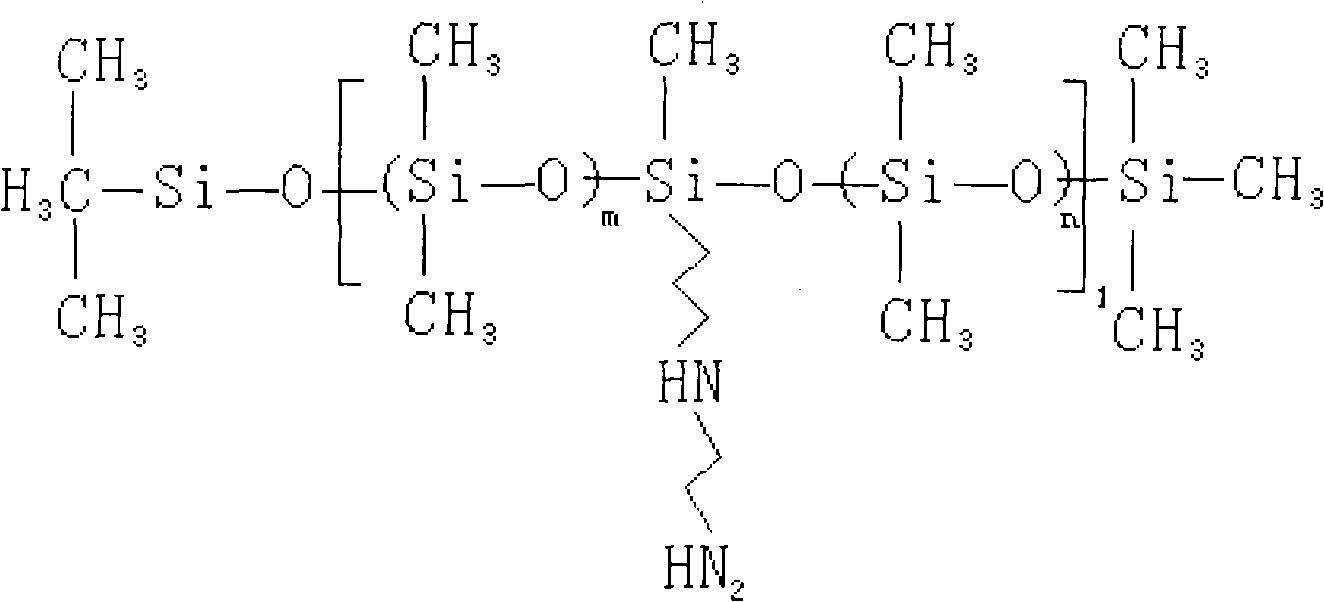

Amino silicone modified waterborne polyurethane and preparation method thereof

A technology of water-based polyurethane and amino silicon, which is applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of hydroxyl-terminated and amino-terminated silicon raw materials, hydroxyl silicon is easy to decompose and break, and the cost is high, so as to achieve simple and optimized production process Effect of letdown performance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1), an amino silicon-modified water-based polyurethane, which is prepared from the following raw materials in parts by weight: polyether N220: 192.94, isophorone diisocyanate (IPDI): 120.22, dimethylol propionic acid (DMPA): 17.54, dibutyltin dilaurate: 0.64, 1,4-butanediol (BDO): 20.10, acetone: 4-5, triethylamine (TEA): 13.24, side chain amino silicone oil: 8.04, to Ionized water 627.27.

[0026] (2), preparation method:

[0027] a. Add polyether N220 in a four-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser in parts by weight, vacuumize and dehydrate at 110°C for 1 hour, then cool down to 60°C, and add isophorone diisocyanate , dibutyltin dilaurate and dimethylolpropionic acid, heated up to 75-80°C and reacted for 2-3 hours to obtain a reaction solution;

[0028] b. Add small molecule chain extender 1,4-butanediol to the reaction solution, control the temperature at 70°C for 2 hours, add acetone during the reaction, reduce the ...

Embodiment 2

[0031] (1), an aminosilicon-modified waterborne polyurethane for leather surface coating, which is prepared from the following raw materials in parts by weight: polyether N220: 210.46, isophorone diisocyanate (IPDI): 108.12, Dimethylol propionic acid (DMPA): 15.78, dibutyltin dilaurate: 0.7, 1,4-butanediol (BDO): 16.41, acetone: 4-5, triethylamine (TEA): 11.90, side chain Amino silicone oil: 7.02, deionized water 629.62.

[0032] (2), preparation method is with embodiment 1.

Embodiment 3

[0034] (1), a kind of aminosilicon modified waterborne polyurethane that is used for waterborne wood coating surface finishing, it is prepared by the raw material of following weight ratio: polycarbonate diol: 157.70, isophorone diisocyanate ( IPDI): 145.13, dimethylolpropionic acid (DMPA): 17.52, stannous octoate: 0.53, trimethylolpropane (TMP): 4.72, 1,4-butanediol (BDO): 25.35, acetone: 4 -5. Triethylamine (TEA): 13.21, side chain amino silicone oil: 9.02, deionized water 626.65.

[0035] (2), preparation method:

[0036] a. Add polycarbonate diol in a four-necked flask equipped with an electric stirrer, a thermometer and a reflux condenser in parts by weight, vacuumize and dehydrate at 110°C for 1 hour, then lower the temperature to 60°C, and add Isophor Ketone diisocyanate, stannous octoate and dimethylolpropionic acid are heated up to 75-80°C and reacted for 2-3 hours to obtain a reaction solution;

[0037] b. Add the mixed trimethylolpropane and 1,4-butanediol mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com