Mud-resistant polycarboxylic acid water reducer and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of poor adaptability, no dispersibility and poor dispersibility of cement, and achieve the effects of high water reducing rate, good dispersibility and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

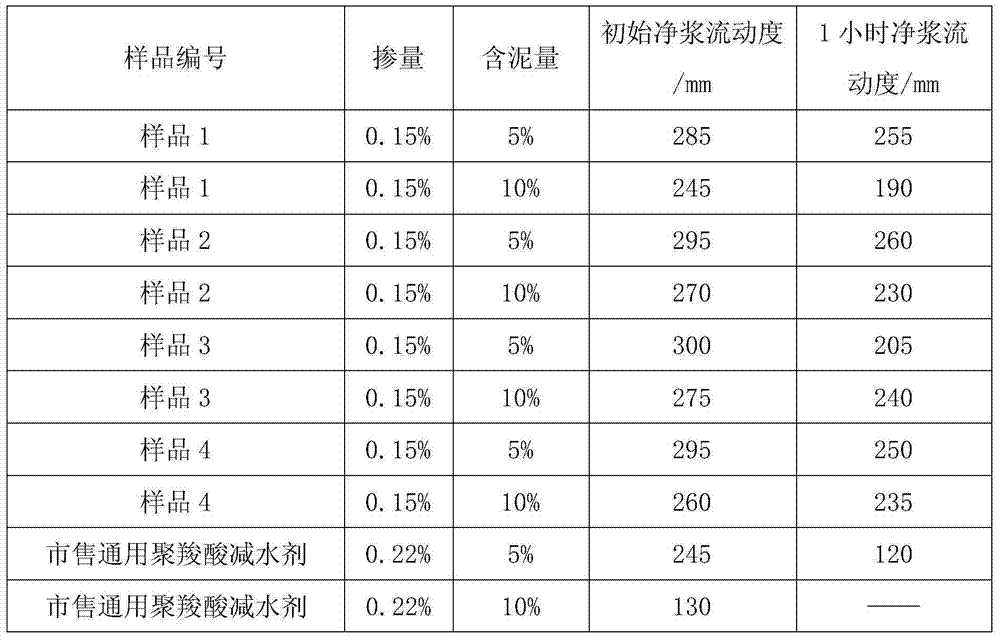

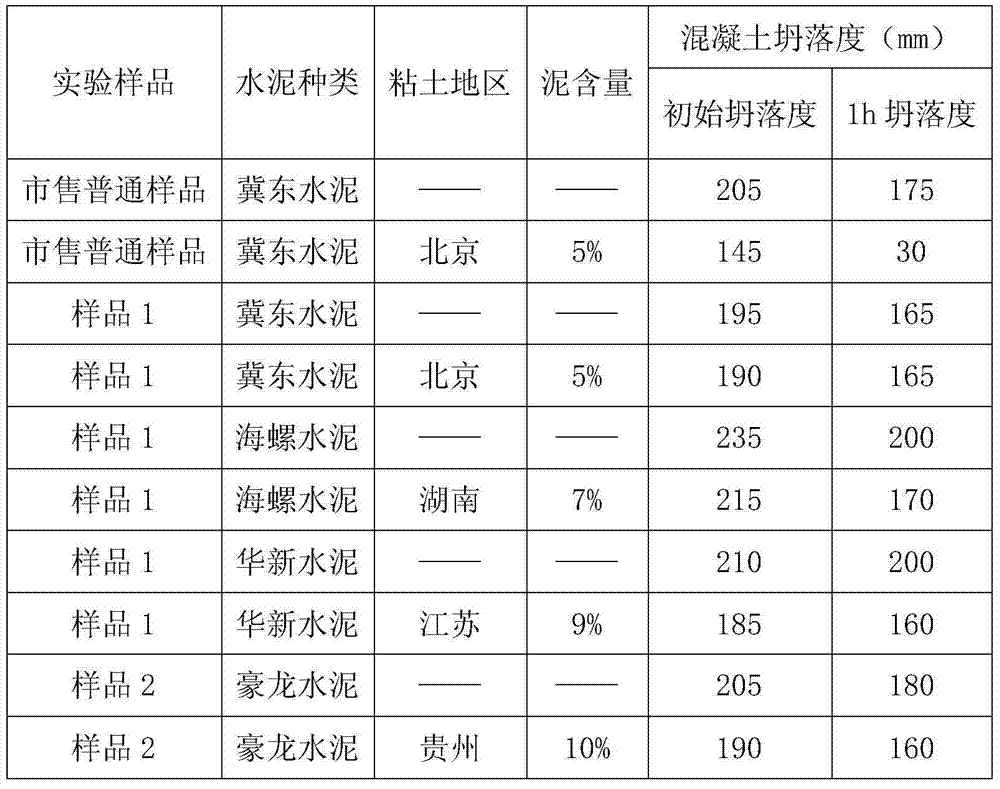

Examples

Embodiment 1

[0024] Vinyl polyoxyethylene ether: sodium styrene sulfonate: acrylic acid: water: acrylamide: ammonium persulfate: mercaptoethanol: potassium hydroxide = 1.0: 0.9: 2.5: 180: 0.3: 0.2: 0.5 (all components According to mole ratio), the temperature was raised to 60°C, and a colorless viscous transparent liquid was obtained after 5 hours of polymerization.

Embodiment 2

[0026] Vinyl polyoxyethylene ether: sodium styrene sulfonate: acrylic acid: water: methylol acrylamide: hydrogen peroxide: thioglycolic acid: tetramethylethylenediamine = 1.0: 1.0: 3.0: 180: 0.15: 0.1: 0.35 (the molar ratio of each component) was fed, the temperature was raised to 65°C, and a yellow viscous transparent liquid was obtained after 5 hours of polymerization. Example 3

Embodiment 3

[0027] Vinyl polyoxyethylene ether: sodium styrene sulfonate: acrylic acid: water: acrylamidodimethylethanesulfonic acid: potassium persulfate: mercaptopropionic acid: ethanolamine = 1.0: 1.1: 3.5: 180: 0.25: 0.2: 0.4 (the molar ratio of each component) was fed, the temperature was raised to 70° C., and a yellow viscous transparent liquid was obtained after 5 hours of polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com