Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

A large-strain, process-based technology, applied in the field of large-strain X80 dual-phase steel plates, can solve problems such as increasing construction costs, achieve the effects of reducing burdens, being suitable for large-scale industrial production, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

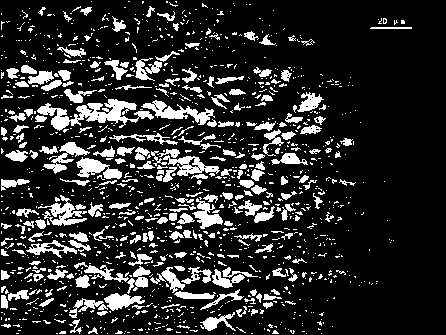

Image

Examples

Embodiment 1

[0040] The large-strain X80 dual-phase steel plate produced by the low-temperature high-reduction process in this example is prepared from the following components by mass percentage: C: 0.05%, Si: 0.25%, Mn: 1.7%, P: 0.008%, S : 0.002%, Cr: 0.25%, Ni: 0.022%, Ti: 0.015%, Pcm=0.19, the balance is Fe and unavoidable impurities.

[0041] The production and preparation method of the large strain X80 dual-phase steel plate produced by the low temperature and high reduction process of the present embodiment is as follows:

[0042] 1) Smelting process: After the raw material molten iron is pretreated by KR, it is smelted in a 210t top-bottom combined blowing converter, the ladle is blown with argon and then sent to the LF refining furnace for refining, and then vacuum treatment is carried out in the VD furnace for 20 minutes. After the treatment is completed Feed calcium-iron wire at 2m / t, and blow argon softly for 10 minutes after feeding the wire;

[0043] 2) Casting process: Aft...

Embodiment 2

[0048] The large-strain X80 dual-phase steel plate produced by the low-temperature and high-reduction process of the embodiment is prepared from the following components by mass percentage: C: 0.065%, Si: 0.23%, Mn: 1.70%, P: 0.010%, S: 0.001%, Cr: 0.22%, Ni: 0.022%, Ti: 0.015%, Pcm=0.18, the balance is Fe and unavoidable impurities.

[0049] The production and preparation method of the large-strain X80 dual-phase steel plate produced by the low-temperature and high-reduction process in this example is the same as that in Example 1, the difference is that the slab stays in the furnace for 4 hours, the surface temperature of the slab after phosphorus removal is 1048°C, and the horizontal stretching and rolling 4 passes, the reduction rates of the 4 passes are 12.8%, 13.8%, 13.9% and 13.4% respectively, and the cumulative reduction rate is 53.9%, 1 pass of longitudinal forming rolling, the reduction rate of each pass is 17.7%, the finish rolling The accumulative deformation rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com