Semi-aromatic polyamide resin and preparation method thereof

A polyamide resin and semi-aromatic technology, which is applied in the field of polymer material synthesis, can solve the problems of weak bonding force between thermal stabilizers and polymers, reduced heat resistance of thermal stabilizers, and inability to achieve long-term thermal stability. Improve product mechanical properties, increase thermal stability, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

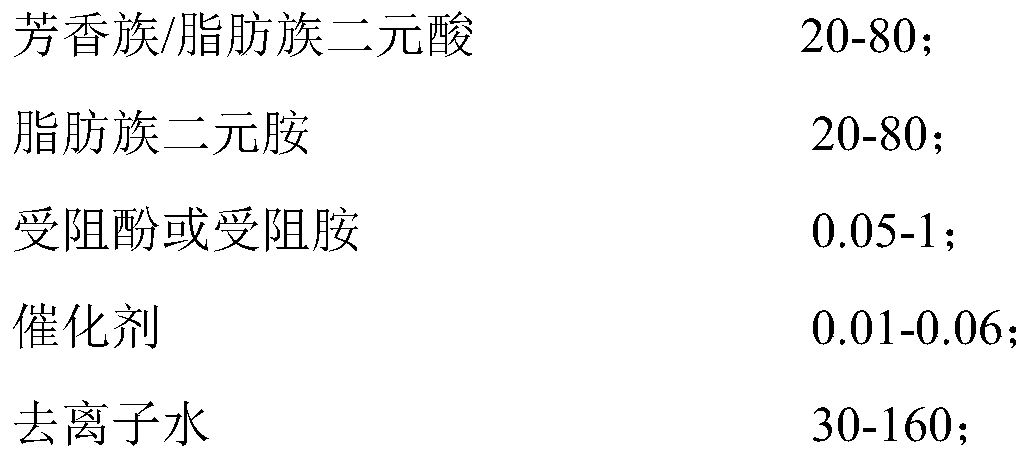

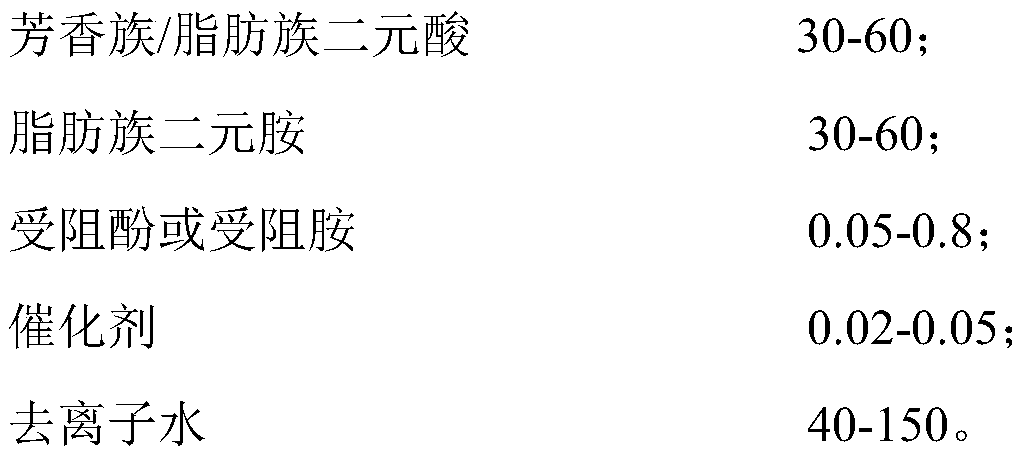

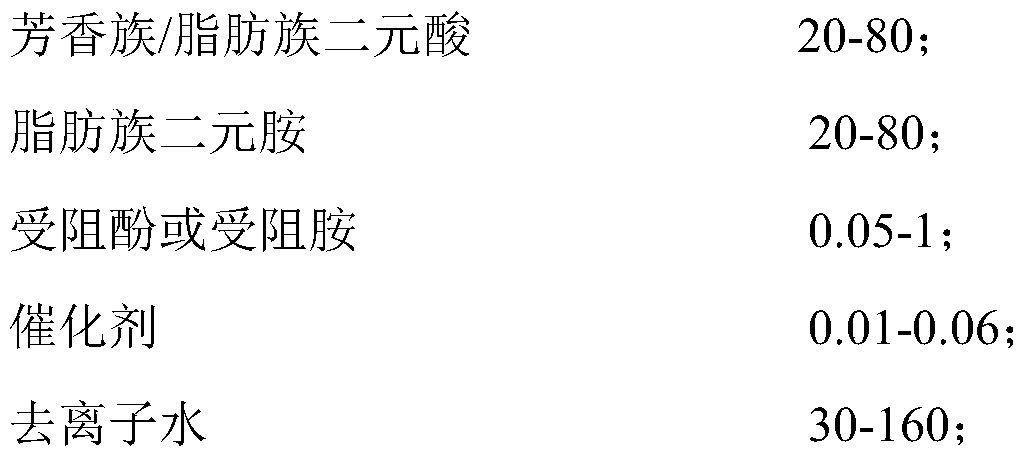

[0056] A kind of preparation method of described semi-aromatic polyamide resin is characterized in that, comprises the following steps,

[0057] S1: Weigh the required aromatic / aliphatic dibasic acid, aliphatic dibasic amine, hindered phenol or hindered amine, catalyst, and deionized water into the autoclave, vacuumize the autoclave, and fill it with nitrogen to Remove the residual air in the reactor, and keep a slight positive pressure in the high-pressure reactor after the replacement; preferably, the slight positive pressure is 10-50kPa;

[0058] S2: Under the condition of stirring, the autoclave is heated and then reacted at a constant temperature, and then the temperature continues to rise. After the pressure reaches 1.2-5MPa, the temperature continues to rise and at the same time, the method of releasing the water vapor in the autoclave makes the interior of the autoclave in a state of In a constant pressure state, when the temperature rises to 240-340°C, slowly release ...

Embodiment 1

[0069] (1) Weigh 830.7g terephthalic acid, 730.7g adipic acid, 1137.7g hexamethylenediamine, 2.5g hindered phenol 2,6-di-tert-butyl-4-aminophenol, 1g catalyst sodium hypophosphite, 1200g Add deionized water into the autoclave, vacuumize the autoclave and fill it with nitrogen, repeat three times to remove the residual air in the autoclave, and keep a slight positive pressure of 25kPa in the autoclave after the replacement is completed;

[0070] (2) Under the condition of 100r / min stirring, the autoclave is heated up to 100°C, reacted at constant temperature for 1.5h, and then continues to heat up to 235°C. After the pressure reaches 2.5MPa, the temperature continues to rise and at the same time, it starts to release the pressure in the autoclave. The method of water vapor keeps the inside of the autoclave in a constant pressure state, and when the temperature rises to 300°C, the autoclave is slowly released to normal pressure within 1 hour;

[0071] (3) Fill the autoclave with...

Embodiment 2

[0073](1) Weigh 1661.3g terephthalic acid, 1686.9g decanediamine, 2.5g hindered amine 2,2,6,6-tetramethylpiperidinamine, 1.3g catalyst sodium phosphite, 2000g deionized water In the autoclave, vacuumize the autoclave and fill it with nitrogen, repeat three times to remove the residual air in the autoclave. After the replacement is completed, the autoclave retains a slight positive pressure of 40kPa;

[0074] (2) Under the condition of 200r / min stirring, the autoclave is heated up to 150°C, reacted at constant temperature for 2 hours, and then continues to heat up to 240°C. After the pressure reaches 3MPa, the temperature continues to rise and at the same time, it begins to release water vapor in the autoclave. The method is to keep the autoclave in a constant pressure state, and when the temperature is raised to 315 ° C, the autoclave is slowly released to normal pressure within 1.5 hours;

[0075] (3) Fill the autoclave with nitrogen to a pressure of 0.3 MPa, extrude the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com