Method for comprehensively recycling manganese, lead, silver and selenium from manganese anode slime

A technology of manganese anode slime and anode slime, which is applied in the field of resource recycling and circular economy, can solve the problems of waste of resources, complex pyrite composition, and inability to recycle selenium, so as to improve comprehensive recovery and recycling, and the source of reducing agent Reliable, good chemically driven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

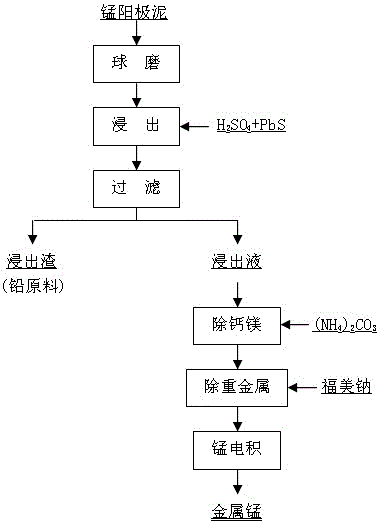

Image

Examples

Embodiment 1

[0053] The zinc anode slime whose composition is: Mn 45.18wt%, Pb6.65wt%, Ag0.0694wt%, Se0.27wt%, Fe0.24wt%, Ca0.42wt%, Mg0.43wt% is comprehensively recycled.

[0054] Manganese anode slime, 1.3 times the required theoretical amount of lead sulfide concentrate containing 60wt% Pb, and ball milling liquid are wet ball milled to a particle size of 85% and pass -180 mesh, and then acidic solution is added to make the solid-liquid mass ratio 1:10 Carry out leaching, add activator ferric sulfate at 0.5g / L in the process of heating up, when solution temperature reaches 85 ℃, react for 8h, measure the pH of leaching end-point to be 1.5, after filtering, obtain manganese and selenium respectively 48.93g / L and 48.93g / L and 0.257g / L manganese sulfate solution and lead-silver leaching slag, containing Pb62.95wt% in the lead-silver leaching slag, used as raw materials for lead smelting, wherein the recovery rates of lead and silver were 99.15wt% and 98.65wt% respectively, selenium in the l...

Embodiment 2

[0057] The zinc anode slime whose composition is: Mn 45.18wt%, Pb6.65wt%, Ag0.0694wt%, Se0.27wt%, Fe0.24wt%, Ca0.42wt%, Mg0.43wt% is comprehensively recycled.

[0058] Manganese anode slime, 1.1 times the required theoretical amount of lead sulfide concentrate containing 65wt% Pb, and ball milling liquid are wet ball milled to a particle size of 86% and pass -180 mesh, and then acidic solution is added to make the solid-liquid mass ratio 1:4 Carry out leaching, add activator ferrous sulfate by 1g / L in the process of heating up, when solution temperature reaches 90 ℃, react for 15h, measure the pH of leaching end-point to be 2, obtain manganese and selenium after filtering and be respectively 110.95g / L and selenium. 0.662g / L manganese sulfate solution and lead-silver leaching slag, containing Pb66.18wt% in the lead-silver leaching slag, used as raw materials for lead smelting, wherein the recovery rates of lead and silver were 99.29wt% and 98.85 wt% respectively, selenium in the...

Embodiment 3

[0061] The zinc anode slime whose composition is: Mn 45.18wt%, Pb6.65wt%, Ag0.0694wt%, Se0.27wt%, Fe0.24wt%, Ca0.42wt%, Mg0.43wt% is comprehensively recycled.

[0062] Manganese anode slime, 1.2 times the required theoretical amount of lead sulfide concentrate containing 70wt% Pb, and ball milling liquid are wet ball milled to a particle size of 88% and pass -180 mesh, and then acidic solution is added to make the solid-liquid mass ratio 1:7 Carry out leaching, add activator ferrous sulfate at 0.7g / L during the heating process, when the temperature of the solution reaches 88°C, react for 10h, the pH of the leaching end point is measured to be 1.7, and the manganese and selenium are respectively 63.52g / L after filtration. and 0.35g / L manganese sulfate solution and lead-silver leaching slag, containing Pb65.38wt% in the lead-silver leaching slag, as the raw material for lead smelting, wherein the recovery rate of lead-silver is 99.18wt% and 98.60 wt% respectively, in the leachate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com