Large-fluidity spread concrete and preparation method thereof

A concrete and fluidity technology, applied in the field of concrete materials, can solve the problems of inability to have both fluidity and slump retention properties of concrete, and achieve the effects of smooth and uniform paving quality, good dispersibility, and uniform and stable dispersed phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

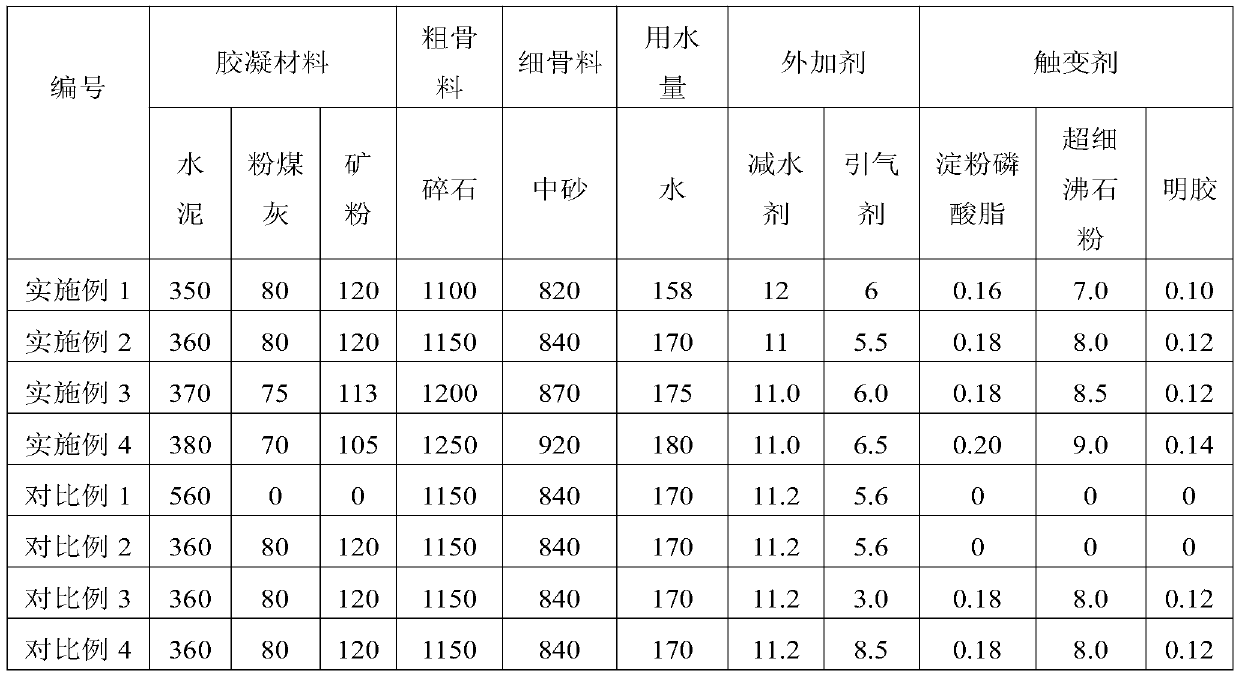

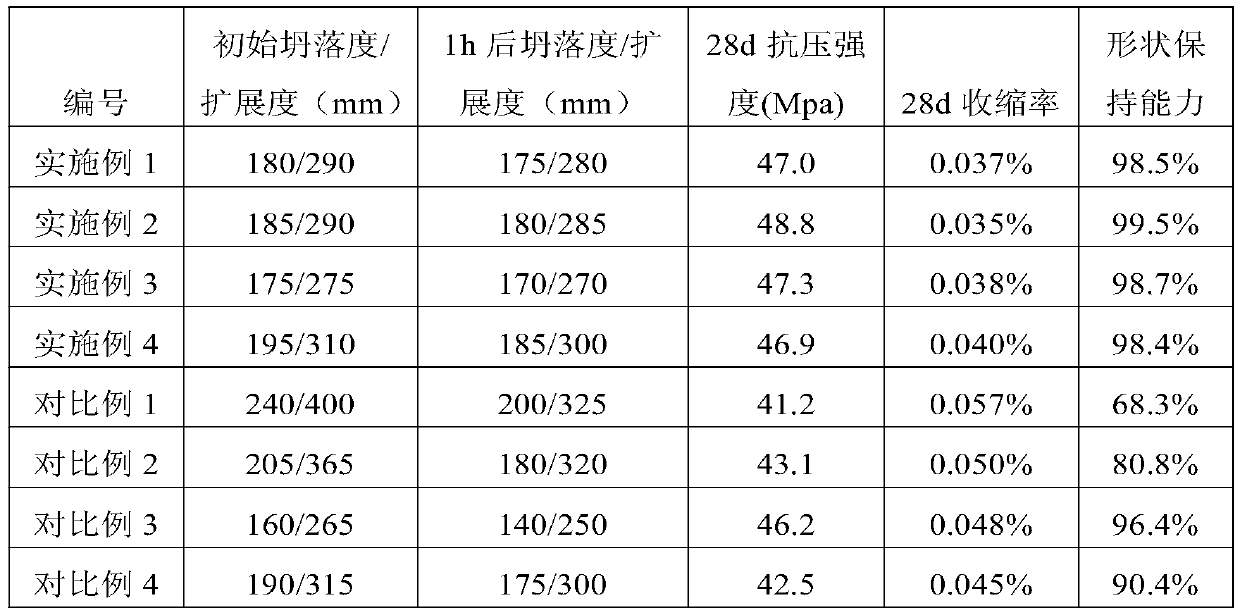

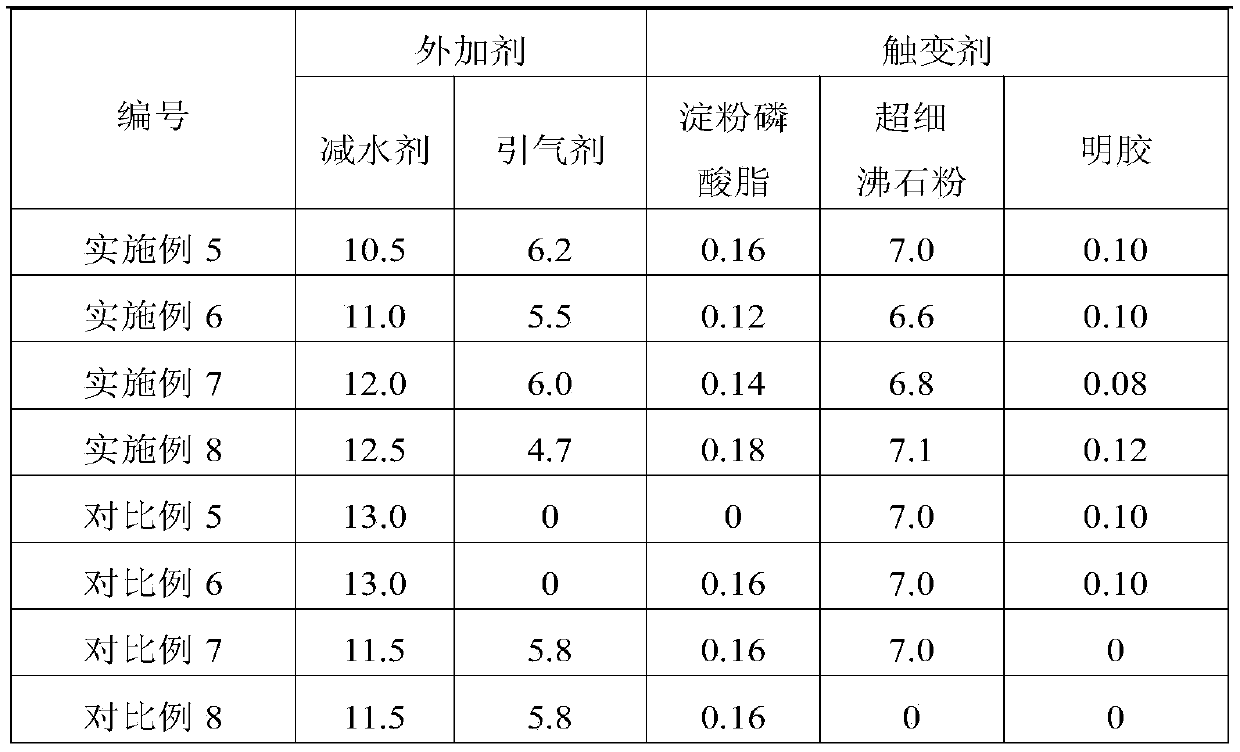

[0023] The mixing ratios of concrete examples 1-4 of the present invention and comparative examples 1-4 are shown in the following table 1, and the coarse aggregate of the concrete is mixed with low-alkali active mechanism crushed stones of two grades of 5-10mm and 10-16mm The fine aggregate is made of low-alkali active mechanism sand with a fineness modulus of 2.4-2.6, the water-binder ratio is 0.30-0.32, the sand ratio of the concrete is 42%, and the phosphorus content of starch phosphate is 4%. The solid content of the polycarboxylate high-efficiency water reducer is 15%, and the mass percent concentration of the air-entraining agent is 1%.

[0024] The preparation method is to mix and stir cement, pulverized coal, mineral powder, starch phosphate ester, ultrafine zeolite powder and gelatin to make a uniform dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com