Cooking method of automatic cooker

A cooking machine and automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of destroying dishes, destroying ingredients, destroying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The braised chicken in this embodiment illustrates the specific implementation steps and beneficial effects of the present invention.

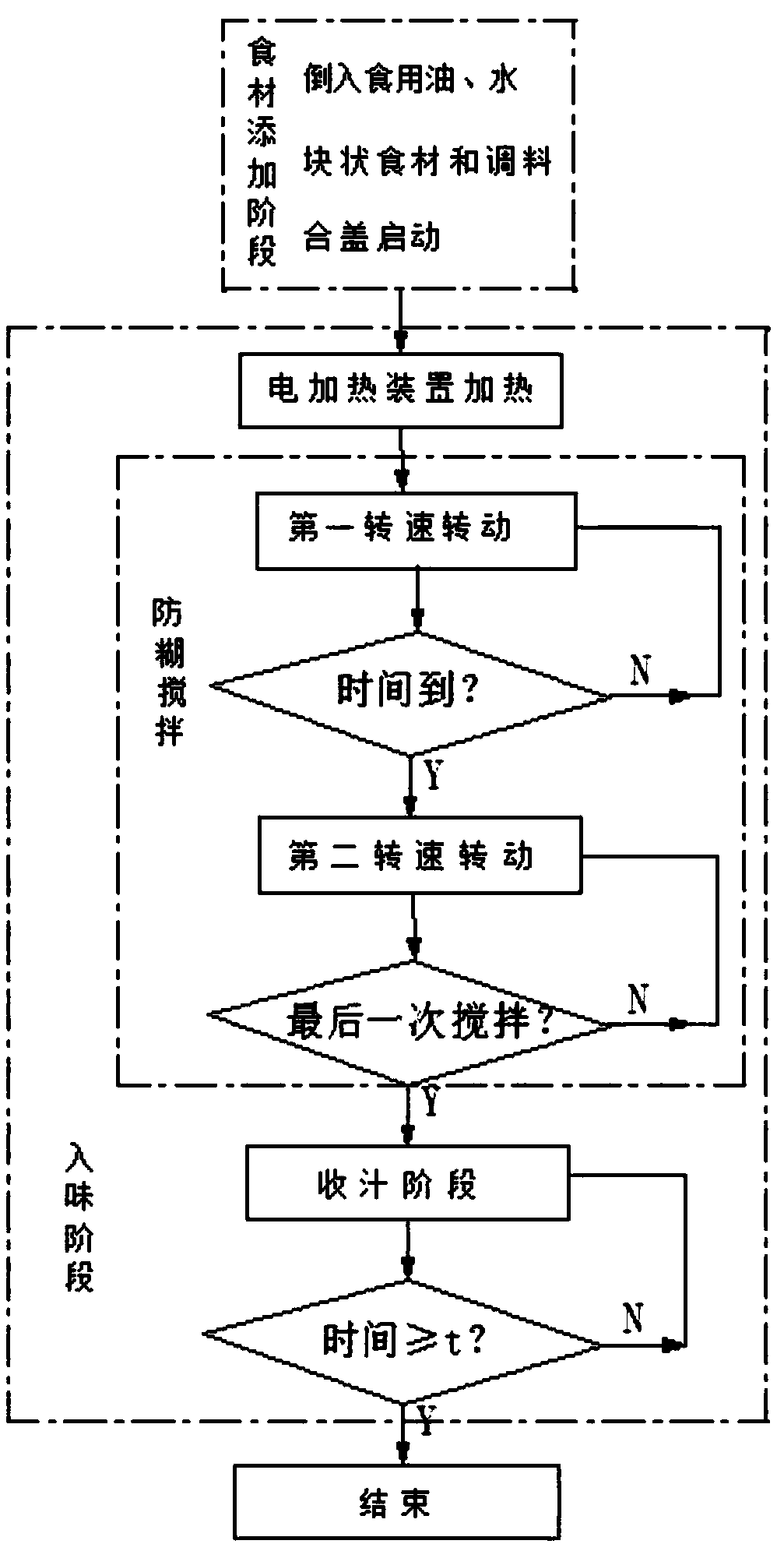

[0034] see figure 1 Shown, a kind of cooking method of automatic cooking machine of the present invention comprises the following steps:

[0035] First of all, the stage of adding ingredients: add cooking oil, a quantity of water, chunky ingredients and seasonings formed by chopped chicken pieces into the frying pan, close the lid and start. In this embodiment, since the oil and water are located at the bottom, it has an anti-sticking effect, and when heated, it is heated first, and the convective heat transfer is relatively uniform, and the fragrance can be burned out quickly. The water of the amount a is 100ml to 500ml of water. In this embodiment, a small amount of water of 200ml is enough.

[0036] Then it enters the taste stage: the electric heating device heats the ingredients in the wok until the preset cooking time t is over,...

Embodiment 2

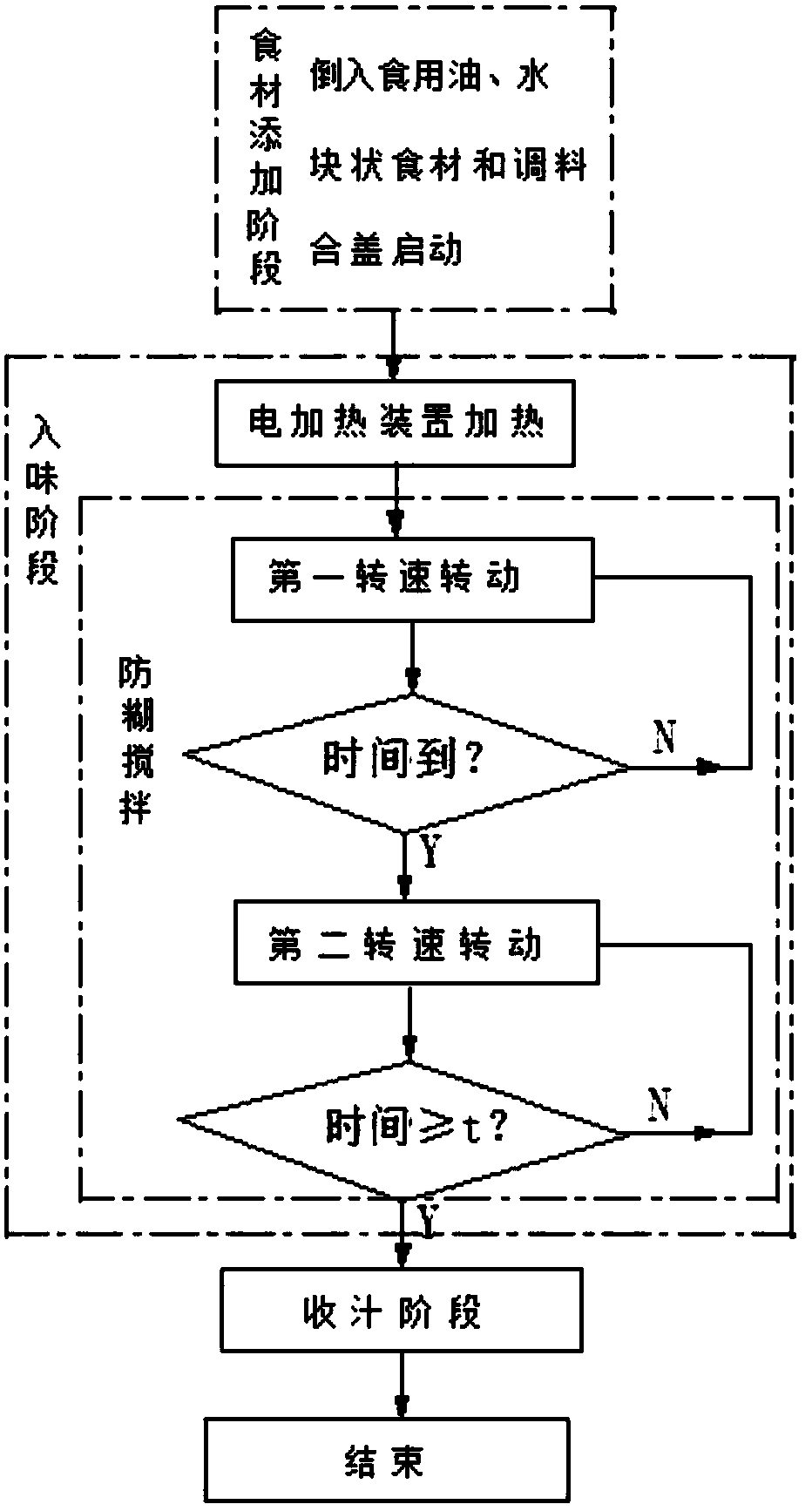

[0046] see figure 2 As shown, the second embodiment of the method of cooking with an automatic cooking machine of the present invention differs from the first embodiment in that the juice collection stage is set separately after the taste stage to reduce the soup and add more flavor, especially for For braised dishes, the taste and color of the dishes after the juice is collected are better.

[0047] The present invention ensures sufficient heating of the dishes and prevents the risk of the dishes sticking to the pot wall and being burnt by controlling the taste stage, setting anti-sticking stirring, specific stirring times and cooking times. In addition, different stirring speeds are set during the taste stage to keep the ingredients full of taste and prevent sticking in the later stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com