Polymer solar cell with subwavelength anti-reflective structure and manufacturing method for polymer solar cell

A solar cell, anti-reflection technology, applied in the field of polymer solar cells, can solve the problems of easy degradation of electrical characteristics with time, no anti-reflection layer structure of polymer solar cells, etc., to improve light conversion efficiency, improve flow characteristics, improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

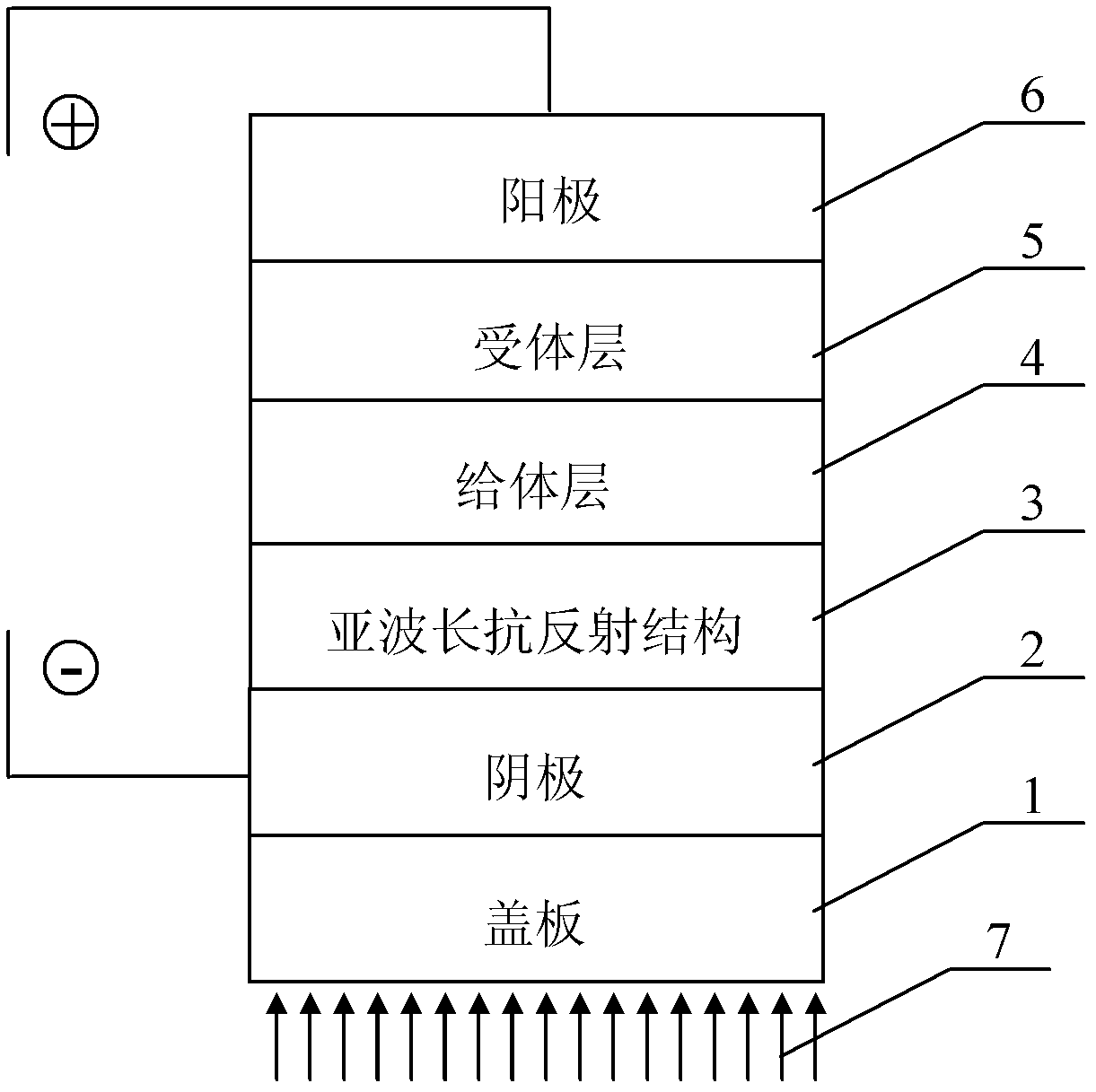

[0043] Such as figure 1 , Image 6 , Figure 7 Shown, a kind of preparation method of the polymer solar cell with sub-wavelength anti-reflection structure comprises the following steps:

[0044] 1) Prepare an imprint mold 8 according to the required sub-wavelength anti-reflection structure 3;

[0045] That is, an imprinting mold 8 is prepared according to the shape, spacing and number of protrusions required, and an imprinting mold 8 with a concave-convex structure opposite to the subwavelength anti-reflection structure 3 is prepared. The imprinting mold 8 can be prepared by the existing LIGA technology, LIGA It is the abbreviation of lithography, electroforming and injection molding. LIGA technology is a MEMS processing technology based on X-ray lithography technology. It is a commonly used micro-nano structure processing method. The material of the imprint mold 8 is silicon or nickel. ;

[0046] 2) Install the embossing mold 8, install the conductive polymer layer, the a...

Embodiment 1

[0051] Such as figure 1 , Image 6 , Figure 7 Shown, a kind of preparation method of the polymer solar cell with sub-wavelength anti-reflection structure comprises the following steps:

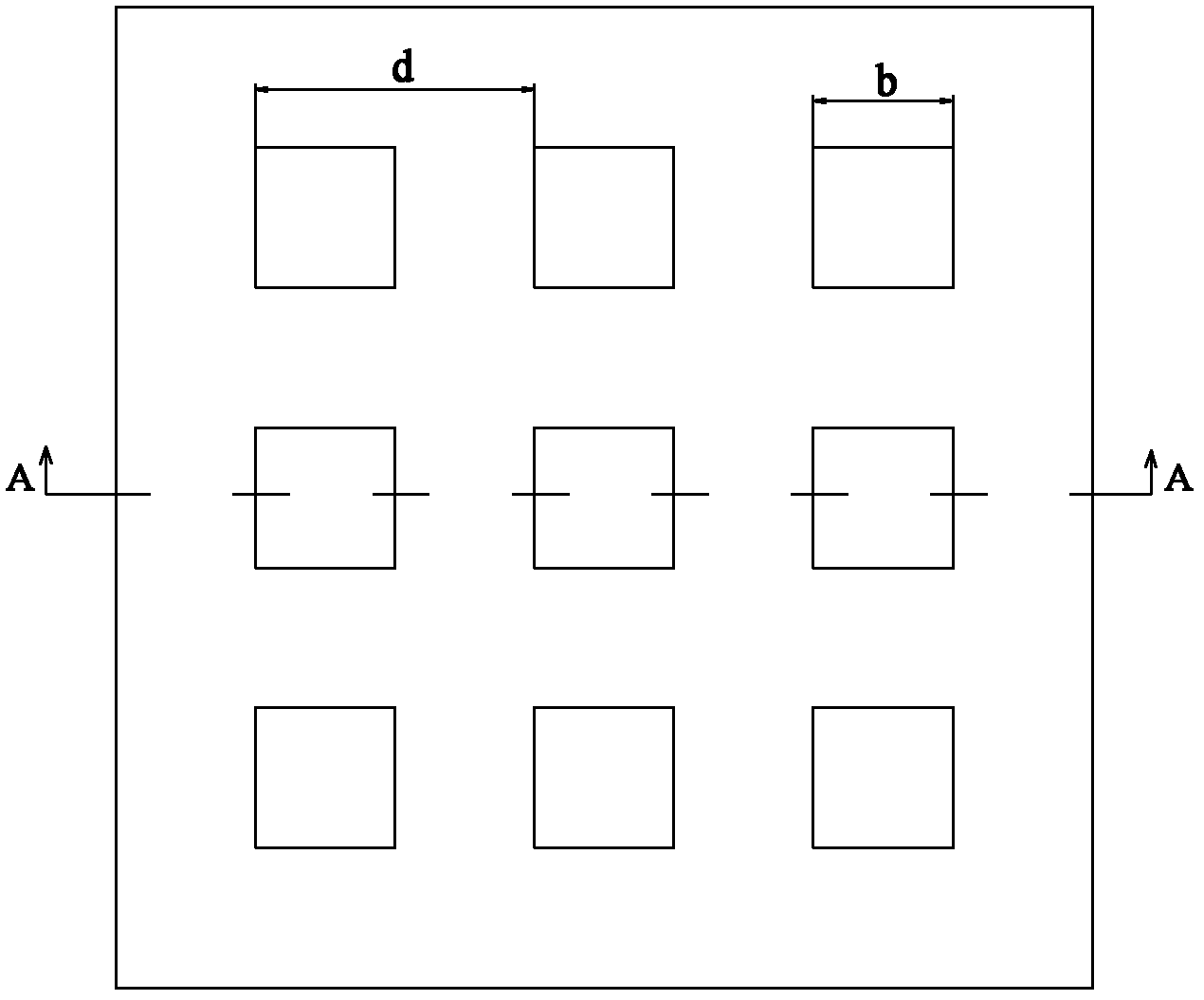

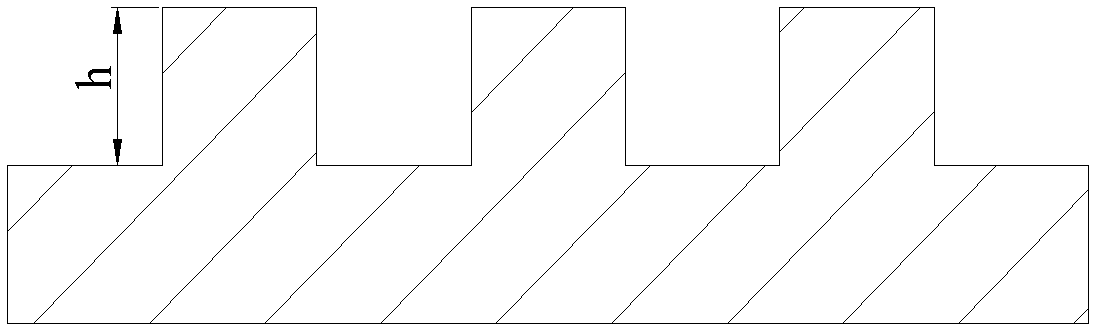

[0052] 1) According to the required sub-wavelength anti-reflection structure 3, such as figure 2 with image 3 As shown, the protrusions are cubes, the structural size is equal to 150nm×150nm×150nm, b=150nm, d=300nm, h=150nm, and the distance between the protrusions is equal to 150nm, and the subwavelength anti-reflection structure 3 is prepared as a concave-convex reverse structure. An imprinting mold 8; the imprinting mold 8 is prepared by the existing LIGA technology, and the material of the imprinting mold 8 is nickel;

[0053] 2) Install the embossing mold 8, install the conductive polymer layer, the acceptor layer 5 and the anode 6 in sequence, and the conductive polymer of the conductive polymer layer (ie, the donor layer 4) is polythiophene (the average molecular weight is 34kD, ...

Embodiment 2

[0059] Such as figure 1 , Image 6 , Figure 7 Shown, a kind of preparation method of the polymer solar cell with sub-wavelength anti-reflection structure comprises the following steps:

[0060] 1) According to the required sub-wavelength anti-reflection structure 3, such as Figure 4 As shown, the protrusions are regular quadrangular pyramids, the distance between adjacent regular quadrangular pyramids is 120nm, the side length of the square bottom of the regular quadrangular pyramids is 200nm, and the height is 150nm, that is, the structural size of the protrusions is 200nm×200nm×150nm. Structure 3: An embossing mold 8 with concave and convex opposite structures; the imprinting mold 8 is prepared by the existing LIGA technology, and the material of the imprinting mold 8 is nickel;

[0061] 2) Install the embossing mold 8, install the conductive polymer layer, acceptor layer 5 and anode 6 in sequence, and the conductive polymer of the conductive polymer layer (ie, the dono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com