Superhard self-lubricating coating tool and preparation method thereof

A self-lubricating coating and tool technology, used in coatings, metal material coating processes, melt spraying and other directions, can solve the problems of severe tool friction and wear and reduced tool life, so as to improve tool life and reduce friction and wear. , the effect of strong binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

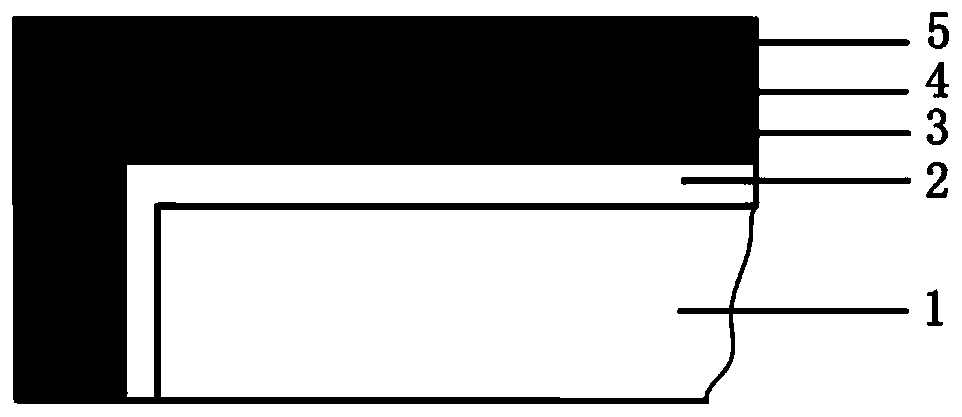

[0018] A super-hard self-lubricating coating tool, the base material of the tool is W9Mo3Cr4V high-speed steel, and the surface of the base has a laminated super-hard self-lubricating layer composed of a hard alloy layer, an alumina ceramic layer, a silicon nitride ceramic layer and a cubic boron nitride layer. Coating, the superhard self-lubricating coating adopts the plasma spraying method to successively clad cemented carbide mixed powder, alumina ceramic layer mixed powder, silicon nitride ceramic mixed powder and cubic Preparation of boron nitride mixed powder. The weight percentage of each component in cemented carbide mixed powder is: 55% WC, 8% TiC, 8% Co, 1% TaN, 20% Ni60A, 2% PbO, 2% Mo, 2% TiB 2 , 0.5% BNNTs, 0.5% CNTs, 1% graphene, the sum of the weight percentages of each material is 100%; the weight percentage of each component in the alumina ceramic mixed powder is: 45% Al2 o 3 , 20% TiC, 20% Ni60A, 4% PbO, 4% Mo, 2% TiB 2 , 2% BNNTs, 2% CNTs, 1% graphene, the...

Embodiment 2

[0027] A super-hard self-lubricating coating tool, the base material of the tool is 9W18Cr4V high-speed steel, and the surface of the base has a laminated super-hard self-lubricating layer composed of a hard alloy layer, an alumina ceramic layer, a silicon nitride ceramic layer and a cubic boron nitride layer. Coating, the superhard self-lubricating coating adopts the plasma spraying method to successively clad cemented carbide mixed powder, alumina ceramic layer mixed powder, silicon nitride ceramic mixed powder and cubic Preparation of boron nitride mixed powder. The weight percentage of each component in cemented carbide mixed powder is: 60%WC, 5%TiC, 5%Co, 2%TaN, 16%Ni60A, 3%PbO, 3%Mo, 3%TiB 2 , 1% BNNTs, 1% CNTs, 1% graphene, the sum of the weight percentages of each material is 100%; the weight percentage of each component in the alumina ceramic mixed powder is: 55% Al 2 o 3 , 15% TiC, 16% Ni60A, 3% PbO, 3% Mo, 3% TiB 2 , 2% BNNTs, 2% CNTs, 1% graphene, the sum of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com