High-strength antistatic transparent polycarbonate film and preparing method thereof

A polycarbonate, antistatic technology, applied in the field of materials, can solve the problems of lower product yield, easy migration, lower transparency, etc., achieve good antistatic performance, solve limitations, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0029] In the following examples 1-3:

[0030] Tin oxide antistatic gels are prepared according to the following preparation method:

[0031] Disperse tin oxide powder with a particle size of 0.5-2um into a water-soluble acrylic resin emulsion (acrylic resin content in the emulsion is 48-52wt%), the mass ratio of tin oxide powder to water-soluble acrylic resin emulsion is 1:4, 60°C Stir until a sol is formed, and then stand at 25°C to form a tin oxide antistatic gel;

[0032] Ultrafine alumina: particle size 100-300nm, white color, specific surface area > 50m 2 / g;

[0033] Ultrafine magnesium oxide: particle size 300-800nm, white color, specific surface area > 80m 2 / g;

[0034] Dendritic macromolecule quaternary ammonium salts are all prepared by grafting three-generation dendritic macromolecules with dodecane bromide or hexadecane bromide. References: Zheng Nengeng, Ye Zhongbin, Guo Yongjun, Su Songtao, Xu Hui , Liu Jianxin. Synthesis and clay stability of two polyamid...

Embodiment 1

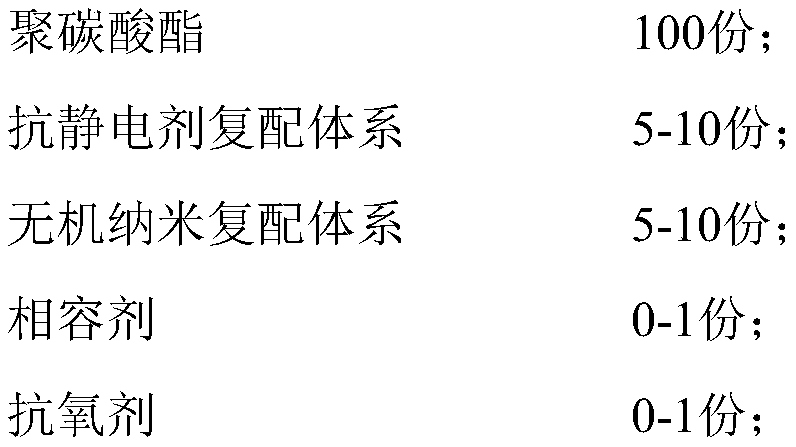

[0037] A high-strength antistatic transparent polycarbonate film is prepared from raw polycarbonate, an antistatic agent compound system, an inorganic nano compound system, a compatibilizer and an antioxidant. The parts by weight of the above-mentioned raw materials are respectively :

[0038] 100 parts of polycarbonate (molecular weight is 50,000-70,000);

[0039] Antistatic agent compound system (according to the mass ratio of tin oxide antistatic gel: dendrimer quaternary ammonium salt is 1:1) 8 parts;

[0040] Inorganic nanocomposite system (according to the mass ratio of superfine alumina: superfine magnesium oxide is 2:1 mixed) 8 parts;

[0041] The compatibilizer is 0.5 part of polymer compatibilizer EVA (molecular weight is 10,000-20,000);

[0042] Antioxidant (antioxidant 1010) 0.5 part.

[0043] The antistatic agent compound system is prepared by directly blending and stirring tin oxide antistatic gel and dendrimer quaternary ammonium salt in proportion for 5-8 mi...

Embodiment 2

[0046] A high-strength antistatic transparent polycarbonate film is prepared from raw polycarbonate, an antistatic agent compound system, and an inorganic nano compound system. The parts by weight of the above raw materials are respectively:

[0047] 100 parts of polycarbonate (molecular weight is 60,000-80,000);

[0048] Antistatic agent compound system (according to the mass ratio of tin oxide antistatic gel: dendrimer quaternary ammonium salt is 3:1) 5 parts;

[0049] Inorganic nano-composite system (mixed according to the mass ratio of ultra-fine alumina: ultra-fine magnesium oxide at 2:3) 5 parts.

[0050] The antistatic agent compound system is prepared by directly blending and stirring tin oxide antistatic gel and dendrimer quaternary ammonium salt in proportion for 5-8 minutes, and drying in an oven at 80°C for 2 hours.

[0051] The preparation method of the high-strength antistatic transparent polycarbonate film: blending the antistatic agent compound system and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com