High-performance-fabric printing method

A technology of fabric printing and printing method, which is applied in the field of textile printing and dyeing, can solve the problems of unfavorable health of workers, easy peeling of color paste film, weak interface fastness, etc., and achieve the increase of fiber surface roughness and porosity, increase of surface roughness and Effect of porosity and strong electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

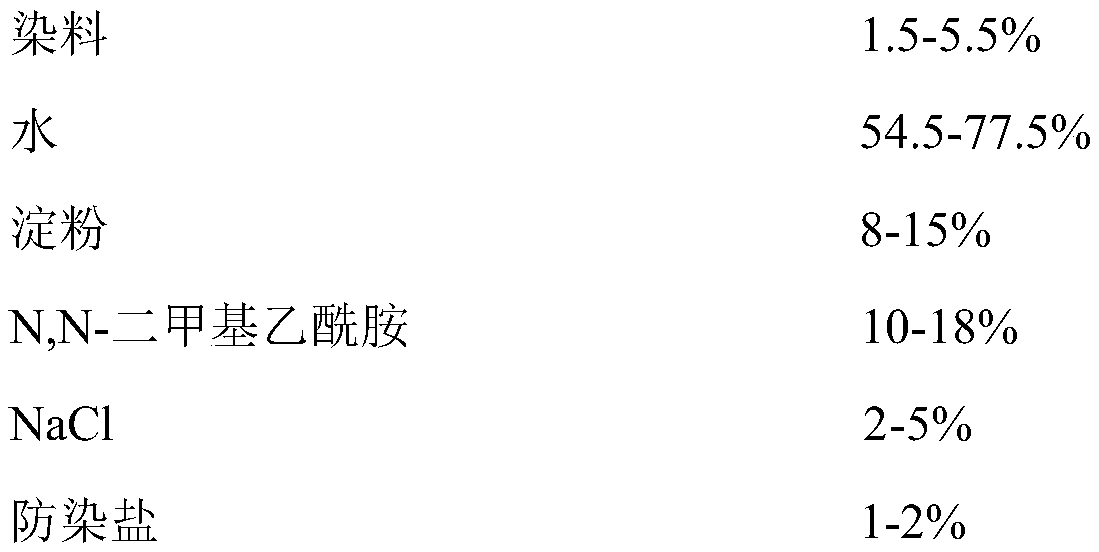

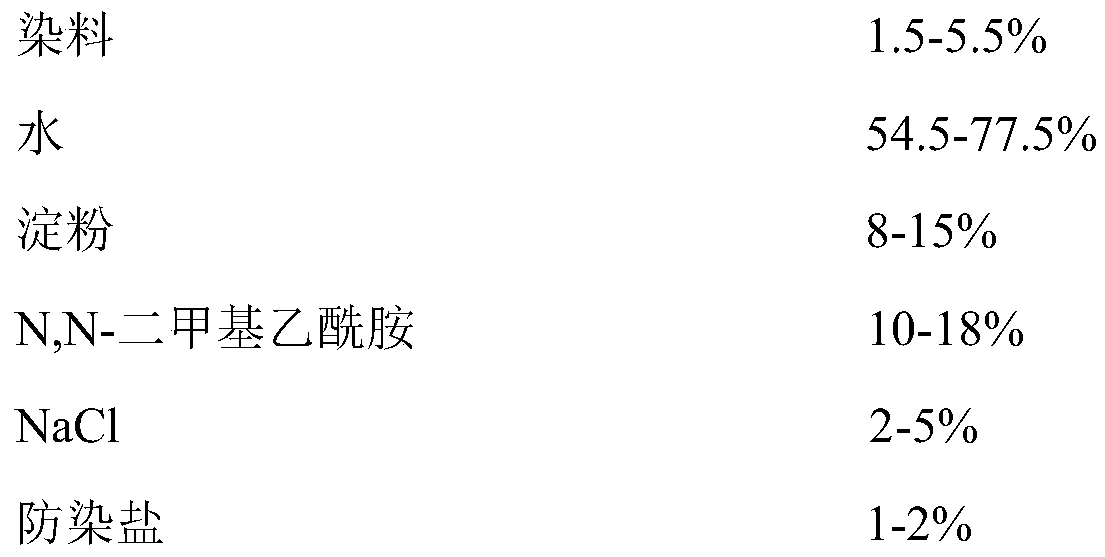

Embodiment 1

[0037] Take 3g of meta-aramid fabric, and prepare a pretreatment solution according to the bath ratio of 1:20. In the pretreatment solution, the mass percentage of N,N-dimethylacetamide is 10%, the mass percentage of sodium silicate is 0.5%, distilled water silicic acid The mass percentage of sodium is 89.5%. After the pre-treatment solution is mixed, stir at 200 rpm for 3 minutes to form a pre-treatment solution. Heat up to 40°C, add the prepared high-performance fabric, continue to heat up to 50°C, and keep it warm for 30 minutes , and then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing high-performance fabrics to 7 at a rate of 2 drops / min, stir evenly, heat up to 70°C, keep warm for 60min, drain, wash, and 85°C Drying; results in a well dyed high performance fabric. The cationic red FBL is used as the dye, and the preparation of the printing paste is as follows: Disperse Scarlet GS dye 1.5%, water 77.5%, starch 8%, N,N-dime...

Embodiment 2

[0039]Take 3g of meta-aramid fabric, and prepare a pretreatment solution according to a bath ratio of 1:20. In the pretreatment solution, the mass percentage of N,N-dimethylacetamide is 30%, the mass percentage of sodium silicate is 10%, distilled water silicic acid The mass percentage of sodium is 60%. After the pre-treatment solution is mixed, stir at 200 rpm for 3 minutes to form a pre-treatment solution. Raise the temperature to 40°C, add the prepared high-performance fabric, continue to heat up to 60°C, and keep it warm for 30 minutes , and then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing high-performance fabrics to 9 at a rate of 2 drops / min, stir evenly, heat up to 80°C, keep warm for 60min, drain, wash, and 85°C Drying; results in a well dyed high performance fabric. The cationic red FBL is used as the dye, and the mass ratio of the printing paste is as follows: Disperse Scarlet GS dye 3.5%, water 66%, starch 11.5%, ...

Embodiment 3

[0041] Take 3g of meta-aramid fabric, and prepare a pretreatment solution according to a bath ratio of 1:20. In the pretreatment solution, the mass percentage of N,N-dimethylacetamide is 50%, the mass percentage of sodium silicate is 20%, distilled water silicic acid The mass percentage of sodium is 30%. After the pre-treatment solution is mixed, stir at 200 rpm for 3 minutes to form a pre-treatment solution. Raise the temperature to 40°C, add the prepared high-performance fabric, continue to heat up to 70°C, and keep it warm for 30 minutes , then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing high-performance fabrics to 11 at a rate of 2 drops / min, then add 5% owf dye, stir evenly, heat up to 90 ° C, keep warm for 60 min, and drain liquid, washed, and dried at 85°C to obtain a high-performance fabric that is dyed well. Disperse scarlet GS is used as the dyestuff, and the preparation of printing paste is as follows according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com