Pre-activated-cellulose thermoplastic material and preparation method thereof

A thermoplastic material and cellulose technology, which is applied in the field of activated pretreatment cellulose thermoplastic material and its preparation, can solve the problems of low production efficiency, insufficient plasticization of cellulose, and insufficient plasticization of cellulose, and achieve Effect of reduced crystallinity, increased accessibility, good flexibility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

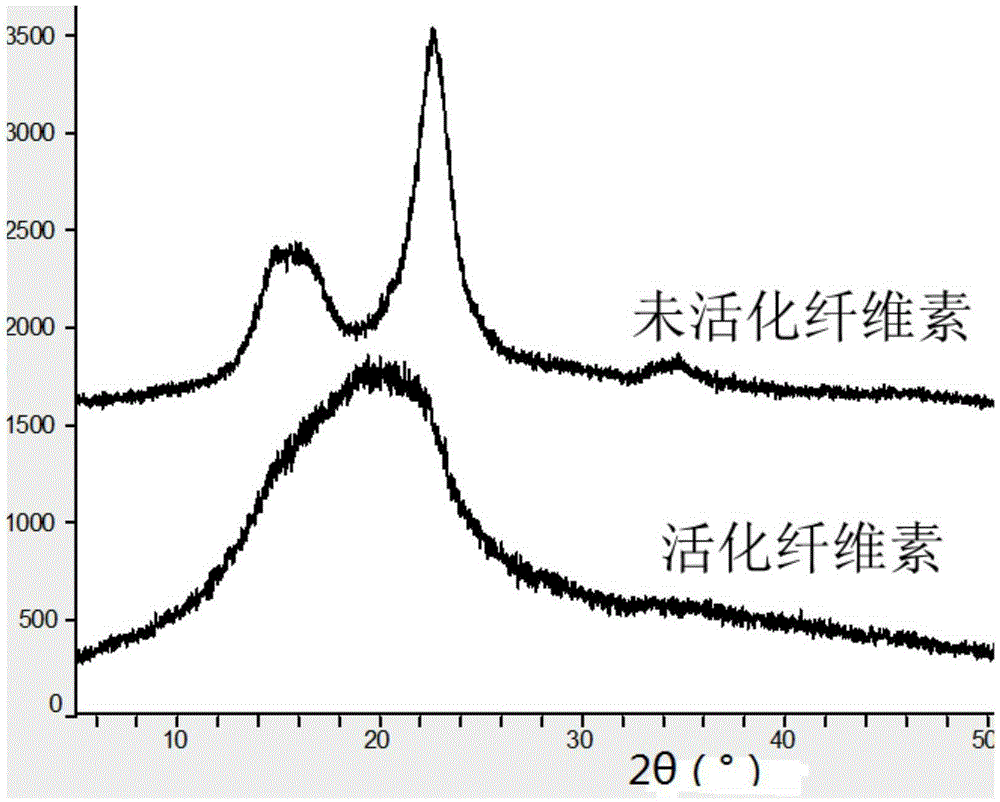

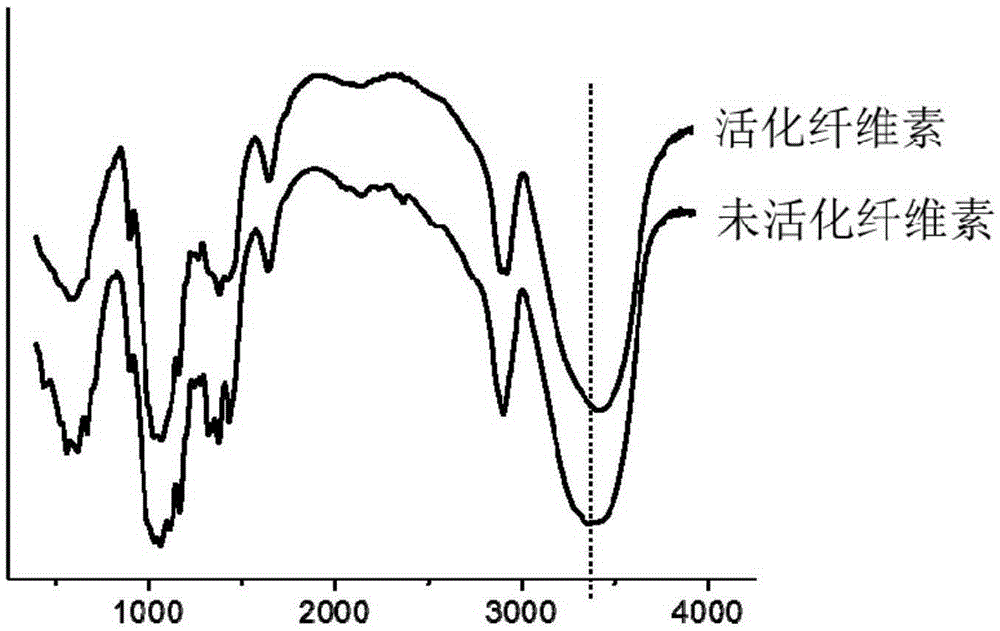

[0035] The bleached kraft wood pulp was crushed into segments with a length of 2 mm and a width of 2 mm, and vacuum-dried at 105° C. for 2 hours. Take 20g of dried cellulose and grind it on a planetary ball mill for 4 hours. The grinding balls are zirconia balls with a diameter of 20mm and 10mm and a quality of 300g. The grinding speed is 540r / min to obtain activated cellulose powder. The particle size of the obtained activated cellulose powder is It is 1-10μm, and the crystallinity is about 0. figure 1 It is the XRD figure before and after the cellulose activation treatment of embodiment 1, after the activation treatment, the cellulose crystallinity reduces; figure 2 It is the infrared image of the cellulose before and after the activation treatment of Example 1. After the activation treatment, the hydroxyl stretching vibration of the cellulose moves to a higher wave number, indicating more free hydroxyl groups or weaker hydrogen bonding.

[0036] Mix the prepared activated...

Embodiment 2

[0038]The bleached kraft wood pulp was crushed into segments with a length of 2 mm and a width of 2 mm, and vacuum-dried at 105° C. for 2 hours. Take 20g of dried cellulose and grind it on a planetary ball mill for 3h. The grinding balls are zirconia balls with a diameter of 20mm and 10mm and a quality of 300g. The grinding speed is 540r / min to obtain activated cellulose powder. The particle size of the obtained activated cellulose powder is It is 15-20μm, and the crystallinity is 20%.

[0039] Mix the prepared activated cellulose powder and 1-allyl-3-methylimidazolium chloride salt in a mass ratio of 50:50 on a high-speed mixer for 5 minutes, then knead the premixed material on an open mill for 20 minutes, and start The kneading temperature is 135° C., and the roller pitch is 0.2 mm to obtain an activated pretreated cellulose thermoplastic material that can be repeatedly thermoformed.

Embodiment 3

[0041] The bleached kraft wood pulp was crushed into segments with a length of 2 mm and a width of 2 mm, and vacuum-dried at 105° C. for 2 hours. Take 20g of dried cellulose and grind it on a planetary ball mill for 2h. The grinding balls are zirconia balls with a diameter of 20mm and 10mm and a quality of 300g. The grinding speed is 540r / min to obtain activated cellulose powder. The particle size of the obtained activated cellulose powder is It is 30-50μm, and the crystallinity is 33.3%.

[0042] Mix the prepared activated cellulose powder and 1-allyl-3-methylimidazolium chloride salt in a mass ratio of 50:50 on a high-speed mixer for 5 minutes, then knead the premixed material on an open mill for 20 minutes, and start The kneading temperature is 135° C., and the roller pitch is 0.2 mm to obtain an activated pretreated cellulose thermoplastic material that can be repeatedly thermoformed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com