Tail gas treatment device for cyclohexane oxidation system and treatment method thereof

A tail gas treatment and tail gas oxidation technology, which is applied in the field of cyclohexane oxidation to prepare cyclohexanol and cyclohexanone, can solve the problems of low heat energy utilization rate, difficult removal of polymers, poor energy saving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

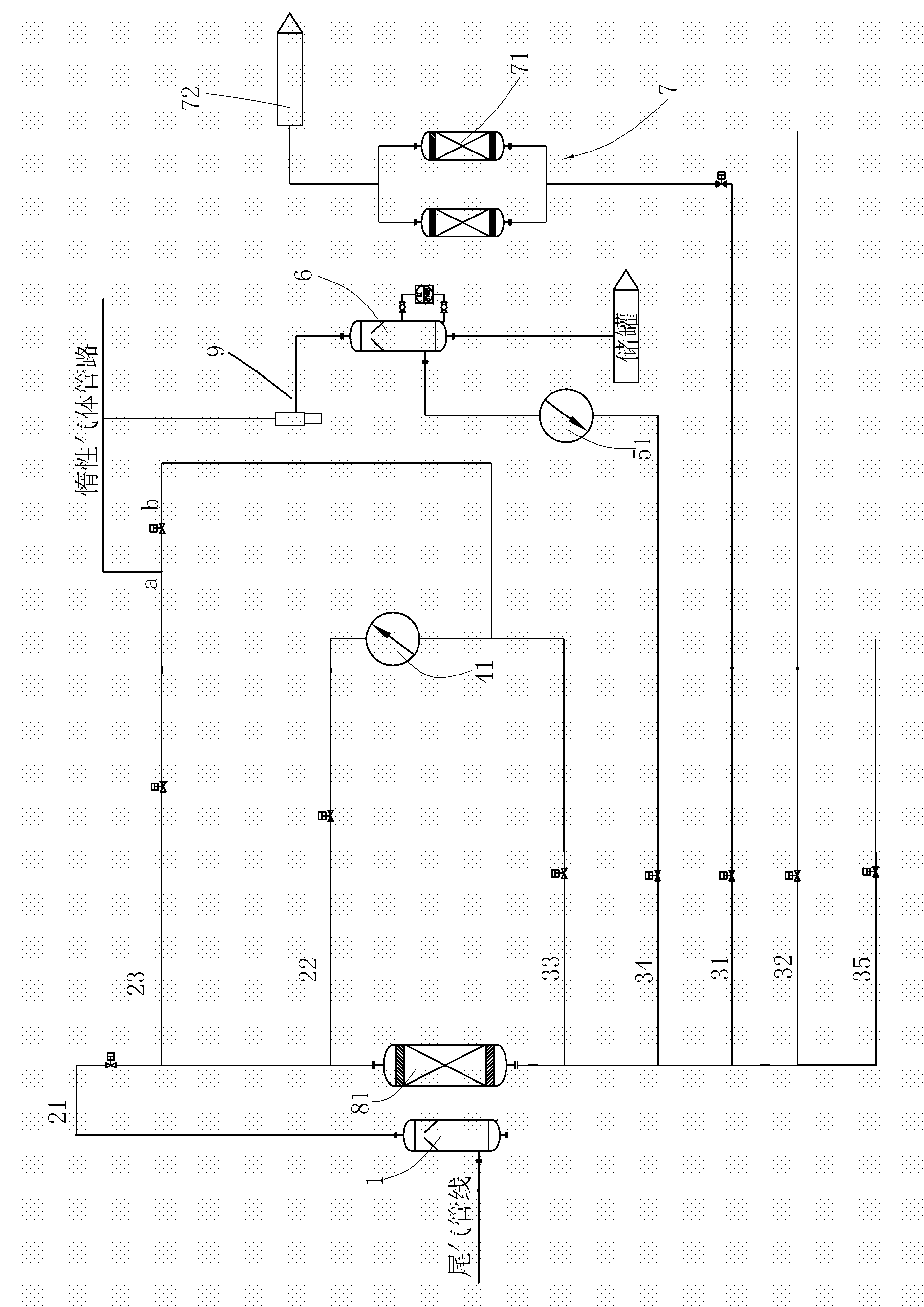

[0066] Such as figure 1 As shown, the cyclohexane oxidation tail gas purification device includes:

[0067] The buffer tank 1 is used to store and buffer the tail gas entering the first temperature swing adsorption tower, and its inlet is connected to the tail gas pipeline to be treated.

[0068] The first temperature swing adsorption tower 81 is filled with adsorbent; the inlet pipeline of the first temperature swing adsorption tower 81 has three branches, wherein the first inlet pipeline 21 is connected to the outlet of the buffer tank 1 through a control valve; the second inlet pipeline 22 The first interface of the first heater 41 is connected through a control valve, and the third inlet pipeline 23 is connected with the first branch a of the inert gas pipeline through a control valve. The second branch b of the inert gas pipeline is connected to the second interface of the first heater 41 through a control valve. There are five outlet pipelines of the first temperature...

Embodiment 2

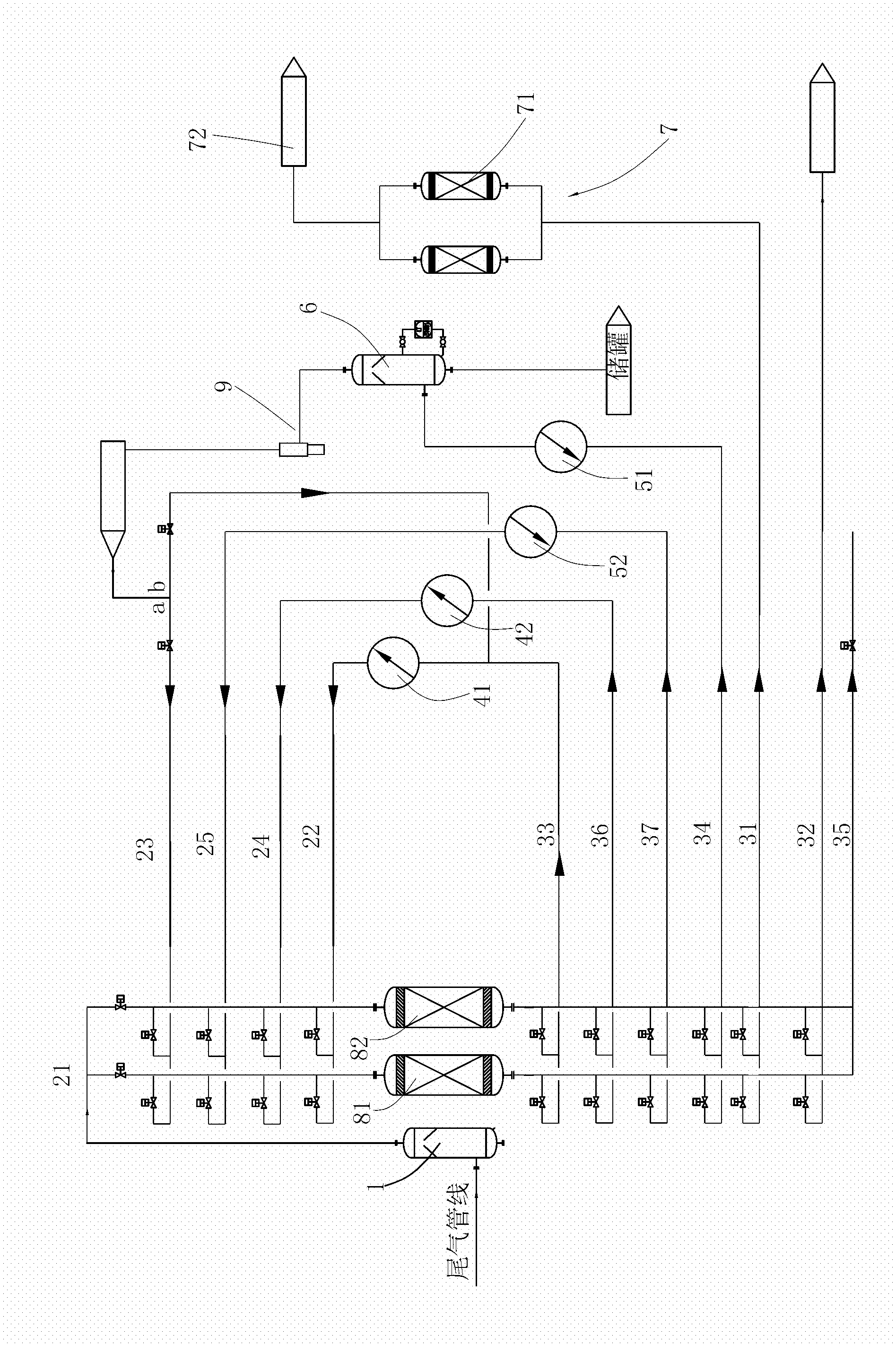

[0087] Such as figure 2 As shown, the cyclohexane oxidation tail gas purification device further includes a second temperature swing adsorption tower 82 , a second heater 42 and a second cooler 52 on the basis of Embodiment 1.

[0088] Wherein, the first temperature swing adsorption tower 81 is connected in parallel with the second temperature swing adsorption tower; the inlet pipeline of each temperature swing adsorption tower also includes the fourth inlet pipeline 24 and the fifth inlet pipeline 25, and the outlet pipeline of each temperature swing adsorption tower also includes A sixth outlet line 36 and a seventh outlet line 37 are included. The fourth inlet pipeline 24 is connected to the first interface of the second heater 42 through a control valve, and the sixth outlet pipeline 36 is connected to the second interface of the second heater 42 through a control valve. The seventh outlet pipeline 37 is connected to the first interface of the second cooler 52 through a ...

Embodiment 3

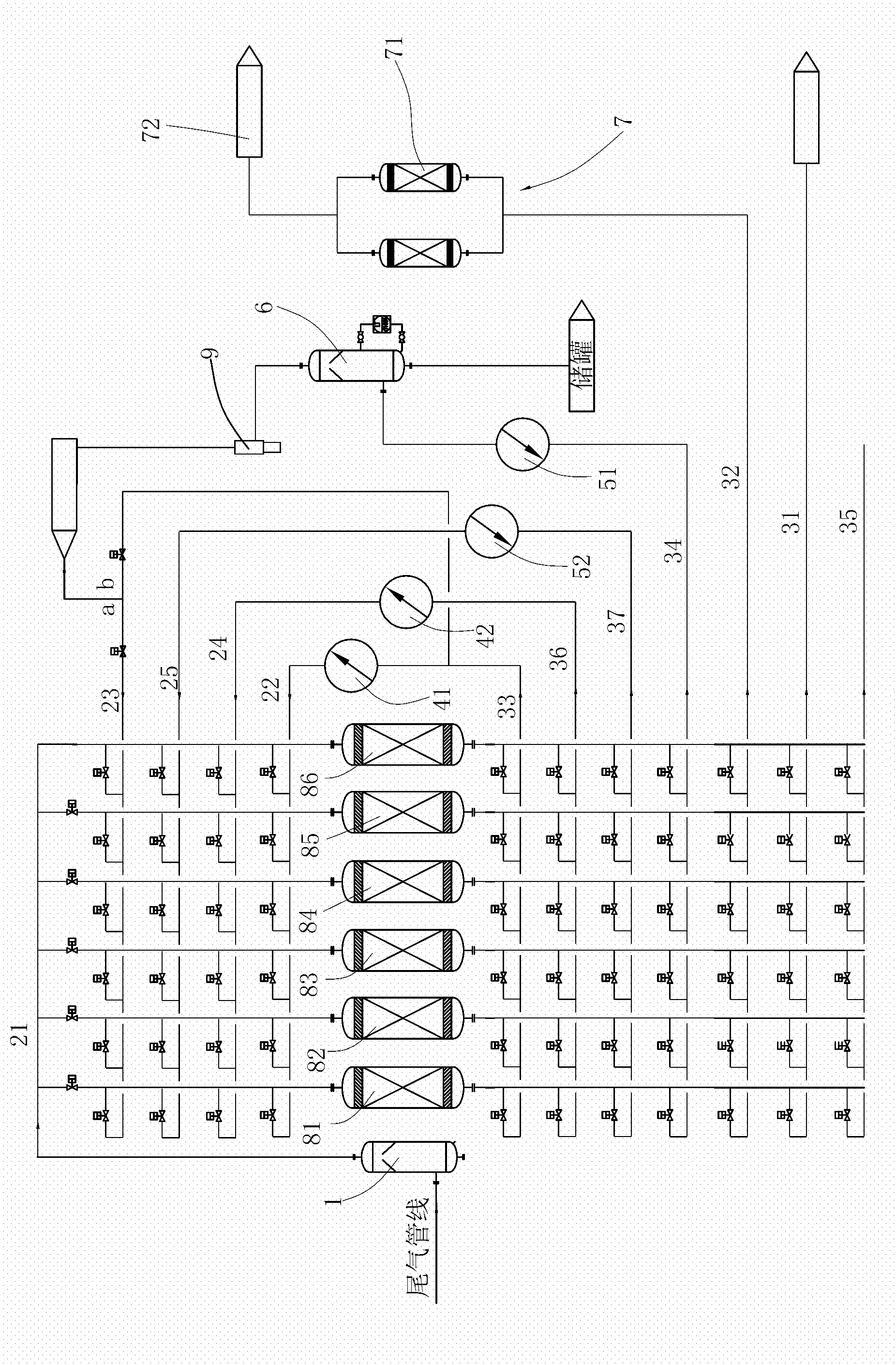

[0105] Such as image 3 with Figure 4 As shown, the cyclohexane oxidation tail gas purification device in this embodiment is used in conjunction with a cyclohexanone device with a capacity of 60,000 to 120,000 tons per year.

[0106] This embodiment is based on the device in Embodiment 2, that is, two temperature swing adsorption towers are used as a group. There are three groups of six temperature swing adsorption towers in this embodiment, namely the first temperature swing adsorption tower 81, the second temperature swing adsorption tower 82. The third temperature swing adsorption tower 83, the fourth temperature swing adsorption tower 84, the fifth temperature swing adsorption tower 85 and the sixth temperature swing adsorption tower 86. These six temperature swing adsorption towers are all connected in parallel, and the adsorption steps, purging steps, desorption steps and blowing and cooling steps are performed alternately, so that the treatment of tail gas can be carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com