Method for synthesizing accelerator DPTU

A technology of accelerators and mixtures, applied in the direction of organic chemistry, etc., can solve the problems of incomplete absorption of liquid caustic soda, and achieve the effects of improving production conditions, complete recovery and increased safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

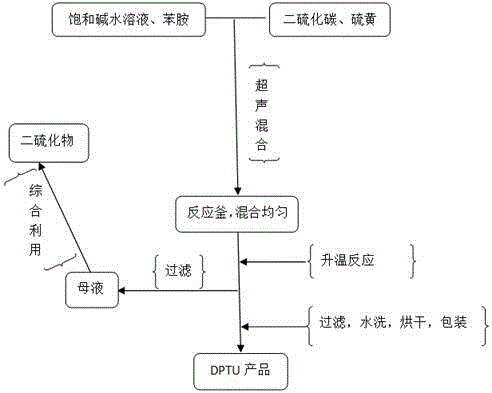

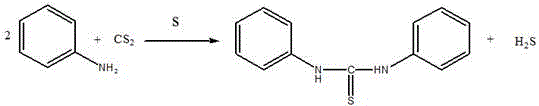

[0037] (1) Take 150g of aniline and 250g of 30wt% sodium hydroxide aqueous solution, mix them evenly under ultrasonic conditions, and then put them into the reaction kettle;

[0038] (2) Take 73g of carbon disulfide and 52g of sulfur, mix them uniformly under ultrasonic conditions, then put them into the reaction kettle, and mix them with the materials in step (1);

[0039] (3) Turn on the reactor to stir, the stirring speed is controlled at 100 rpm, and then the temperature is raised to 40°C for 8 hours.

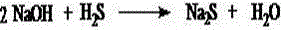

[0040] (4) After the reaction, filter, wash with water, and dry to obtain 171.8g of DPTU product. The filtered mother liquor contains sodium disulfide, which can be used as a raw material for preparing other products.

[0041] The obtained product is a silver-white solid powder with a purity (HPLC) of 99% and a yield of 93.4%.

Embodiment 2

[0043] (1) Take 150g of aniline and 250g of 30wt% sodium hydroxide aqueous solution, mix them evenly under ultrasonic conditions, and then put them into the reaction kettle;

[0044] (2) Take 73g of carbon disulfide and 52g of sulfur, mix them uniformly under ultrasonic conditions, then put them into the reaction kettle, and mix them with the materials in step (1);

[0045] (3) Turn on the reactor to stir, the stirring speed is controlled at 100 rpm, and then the temperature is raised to 70°C for 5 hours.

[0046] (4) After the reaction, filter, wash with water, and dry to obtain 163.8 g of DPTU product with a purity (HPLC) of 99.2% and a yield of 89.1%.

Embodiment 3

[0048] (1) Take 150g of aniline and 250g of 30wt% sodium hydroxide aqueous solution, mix them evenly under ultrasonic conditions, and then put them into the reaction kettle;

[0049] (2) Take 73g of carbon disulfide and 52g of sulfur, mix them uniformly under ultrasonic conditions, then put them into the reaction kettle, and mix them with the materials in step (1);

[0050] (3) Turn on the reactor to stir, the stirring speed is controlled at 100 rpm, and then the temperature is raised to 50°C for 8 hours.

[0051] (4) After the reaction, filter, wash with water, and dry to obtain 177.5 g of DPTU product with a purity (HPLC) of 99% and a yield of 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com