Method for recycling waste LCD (liquid crystal display) panels

A resourceful, panel-based technology, applied in waste treatment, solid waste removal, etc., can solve the problems of complex LCD panel manufacturing process, waste, and complex processing process, and achieve easy industrialization, low cost of recycling equipment, and simple processing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

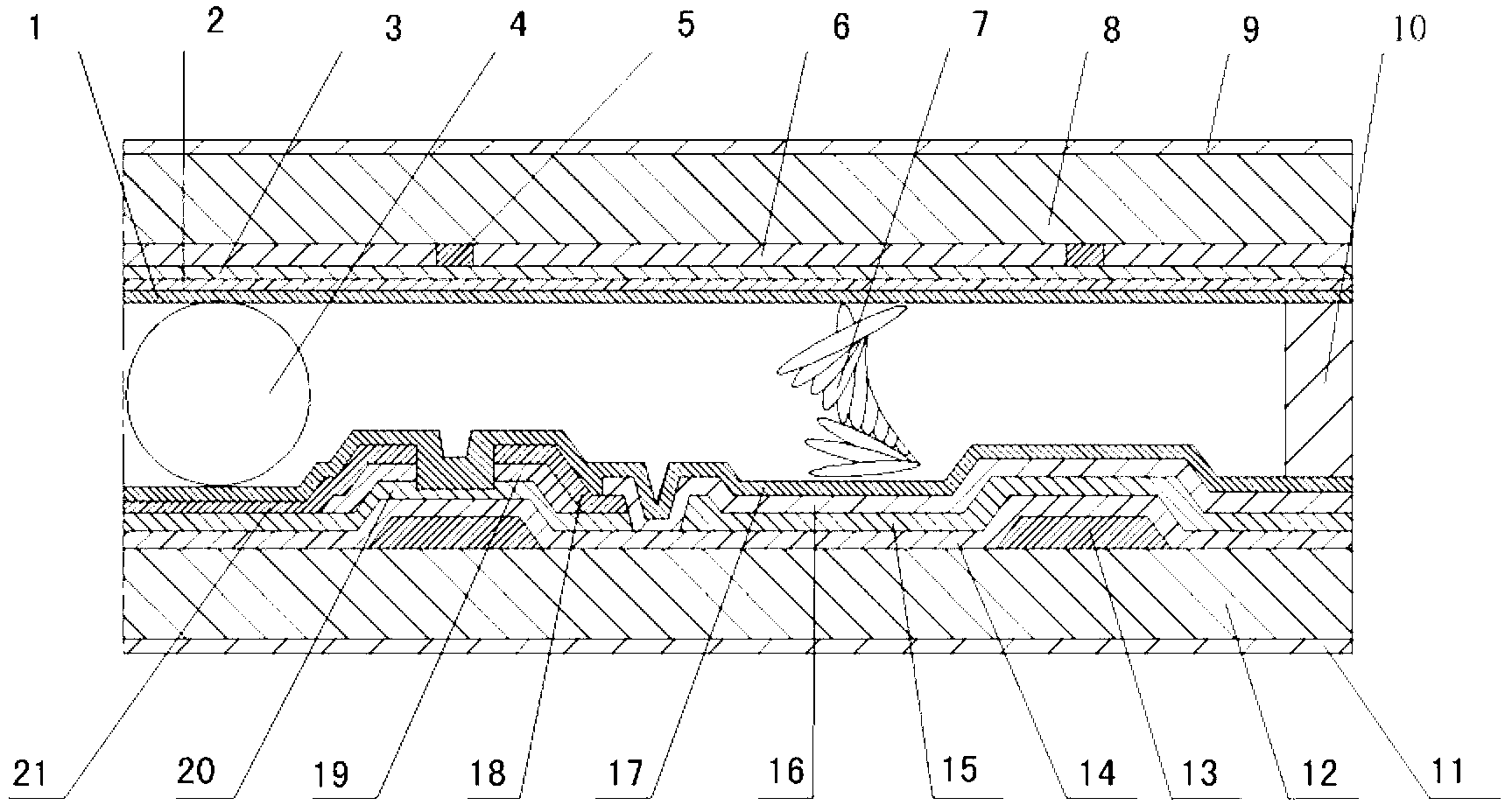

[0024] see figure 1 , the waste LCD panel recycling method in the present embodiment is carried out according to the following steps:

[0025] a. Soak the LCD panel in industrial pure acetone for 13 hours at a temperature of 50°C. Most of the upper polarizer 9 and the lower polarizer 11 in the LCD panel will fall off automatically, and the remaining polarizers will be removed manually with a brush to obtain LCD core without polarizer;

[0026] b. Dry the LCD core and break it into glass fragments with a diameter of less than 15 mm and the surface of which is stained with liquid crystal 7. Wash for 10 minutes to dissolve the liquid crystals on the surface of the glass shards stained with liquid crystals in industrial pure acetone to obtain a liquid-solid mixture; filter the liquid-solid mixture to obtain pretreated glass shards without liquid crystals and a solution containing liquid crystals respectively. The solution containing liquid crystals is passed through a SY-2000 ty...

Embodiment 2

[0030] In this embodiment, the waste LCD panel recycling method is carried out according to the following steps:

[0031] a. Soak the LCD panel in industrial pure toluene at 35°C for 18 hours, most of the upper polarizer 9 and the lower polarizer 11 in the LCD panel will fall off automatically, and the remaining polarizers will be removed manually with a brush to obtain LCD core without polarizer;

[0032] b. Dry the LCD core and break it into glass fragments with a diameter of less than 15 mm and the surface is stained with liquid crystal 7. Place the glass fragments stained with liquid crystal in industrial pure chloroform, and use ultrasonic waves with a frequency of 50KHz and a power of 100W Wash for 12 minutes to dissolve the liquid crystals on the surface of the glass shards stained with liquid crystals in industrial pure chloroform to obtain a liquid-solid mixture; filter the liquid-solid mixture to obtain pretreated glass shards without liquid crystals and a solution c...

Embodiment 3

[0036] In this embodiment, the waste LCD panel recycling method is carried out according to the following steps:

[0037]a. Soak the LCD panel in industrial pure chloroform at 25°C for 24 hours, most of the upper layer polarizer 9 and the lower layer polarizer 11 in the LCD panel will fall off automatically, and the remaining polarizers will be removed manually with a brush to obtain LCD core without polarizer;

[0038] b. Dry the LCD core and break it into glass fragments with a diameter of less than 15 mm and the surface is stained with liquid crystal 7. Place the glass fragments stained with liquid crystal in industrial pure toluene, and use ultrasonic waves with a frequency of 50KHz and a power of 80W Wash for 10 minutes to dissolve the liquid crystals on the surface of the glass shards stained with liquid crystals in commercially pure toluene to obtain a liquid-solid mixture; filter the liquid-solid mixture to obtain pretreated glass shards without liquid crystals and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com