Large-diameter reinforcing steel bar lifting tongs

A large-diameter, fixture technology, applied in the field of hoisting fixtures and large-diameter steel bar hoisting fixtures, can solve problems such as potential safety hazards and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

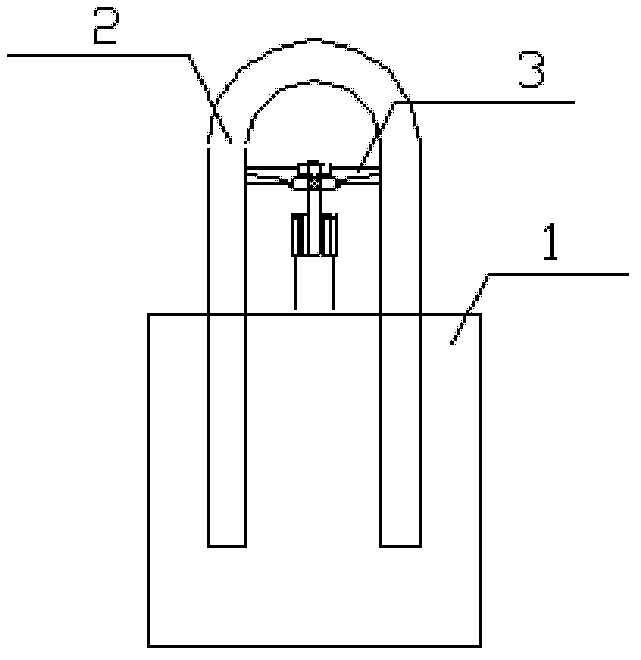

[0019] The large-diameter steel bar hoisting fixture of the present embodiment is as figure 1 and figure 2 As shown, it includes a fixture frame 1 with a groove extending in the horizontal direction, and an inverted U-shaped lifting ring 2 is welded on the fixture frame 1 . The lower side of the groove is the clamping wall 1-1 forming the fixed jaw, and the upper side is the installation wall 1-2 for installing the movable jaw 3-1. The outside (the present embodiment is the upper side) of the installation wall 1-2 is equipped with the clamping handle 3 that drives the movable jaw 3-1 to move towards the direction of the relative fixed jaw 1-1 by a screw pair (this structure is different from that used by existing fitters. The structure of the movable jaw of vise is similar, so it will not be described in detail). The opposite surfaces of the movable jaw 3-1 and the fixed jaw 1-1 are concave arc surfaces with clamping lines. The clamping pattern matches the thread on the la...

Embodiment 2

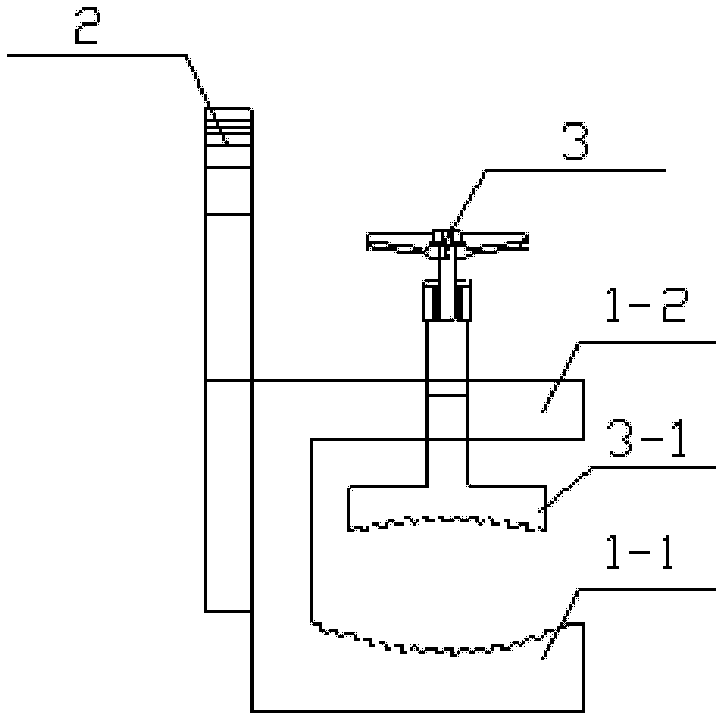

[0022] The large-diameter steel bar hoisting fixture of the present embodiment is as image 3 and Figure 4 As shown, the difference from the first embodiment is that the groove of the fixture frame 1 extends in the vertical direction, so it is suitable for vertical lifting of large-diameter steel bars. In order to ensure that the steel bar is in a vertical state when hoisting, this embodiment is also equipped with Figure 5 As shown in the limiting collar 4, the limiting collar is composed of a horizontal retaining ring 4-1 and a vertical lifting ring 4-2 welded on the retaining ring. When used, such as Figure 8 As shown, the fixture frame 1 is connected with the long sling 8-1, and clamps it at the lower part of the steel bar 6, and the limit collar 4 is connected with the short sling 8-2, and is located at the upper part of the steel bar 6, thereby keeping the large-diameter steel bar 6 at the top of the steel bar 6. Always be in an upright state during hoisting or hois...

Embodiment 3

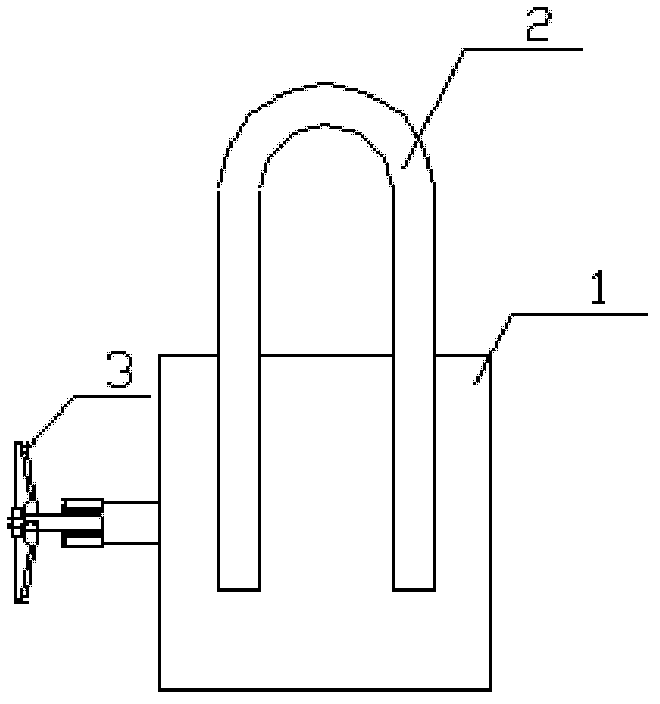

[0024] The large-diameter steel bar hoisting fixture of the present embodiment is as Figure 6 As shown, its structural feature is that the suspension ring is composed of two mutually perpendicular horizontal rings 2-1 and vertical rings 2-2 bent by a steel circle. After clamping the steel bar, you may need to select a suitable ring, so that The same lifting fixture can meet the needs of horizontal lifting or vertical lifting.

[0025] The lifting ring can also be inserted into the corresponding jack of the fixture frame through the indexing shaft. The outer circle of the indexing shaft is made with two positioning depressions with an angular interval of 90 degrees. The fixture frame is made with a positioning hole leading to the jack. Threaded holes in which set screws corresponding to the positioning recesses are installed. Therefore, one of the positioning depressions on the indexing shaft can be tightened by means of set screws as required, so that the length direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com