Vibration self-synchronizing crusher of double vibrators

A vibration exciter and self-synchronization technology, applied in the field of mechanical structure, can solve the problems of over-crushing of products, difficult to control crushing force, and high energy consumption, and achieve the effects of stable operation, reduced energy consumption of production operations, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

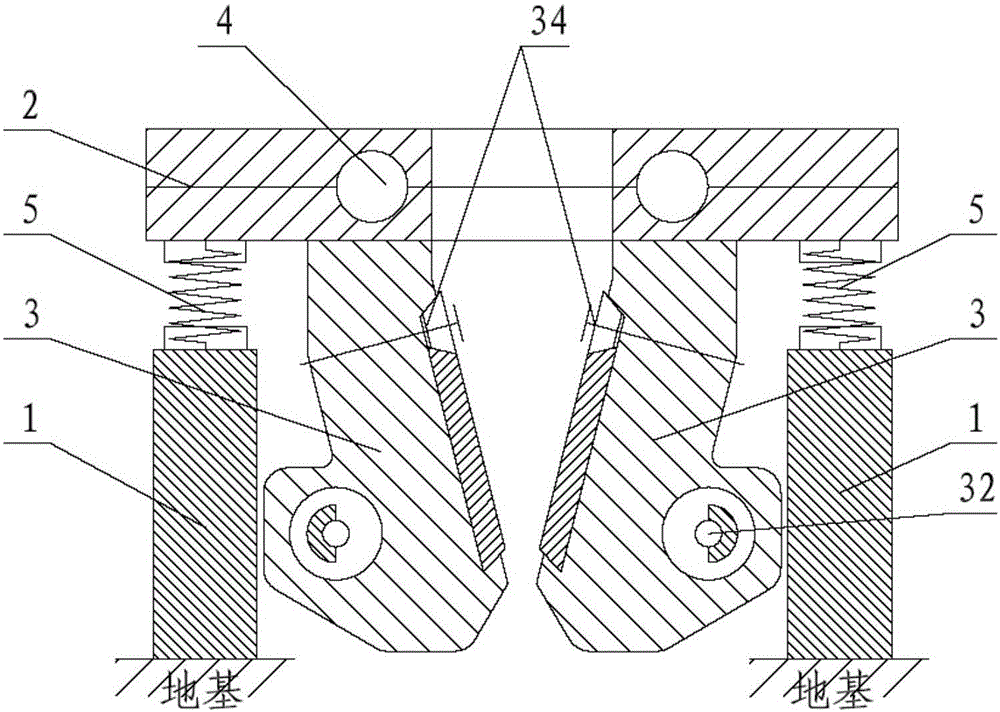

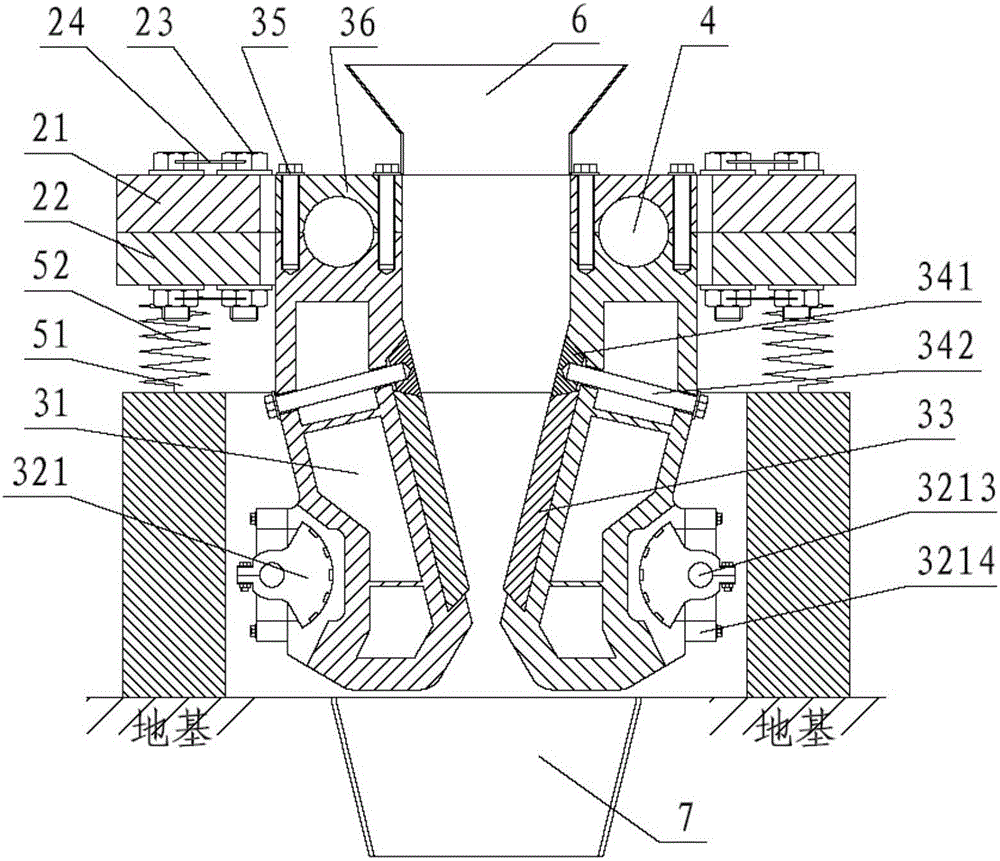

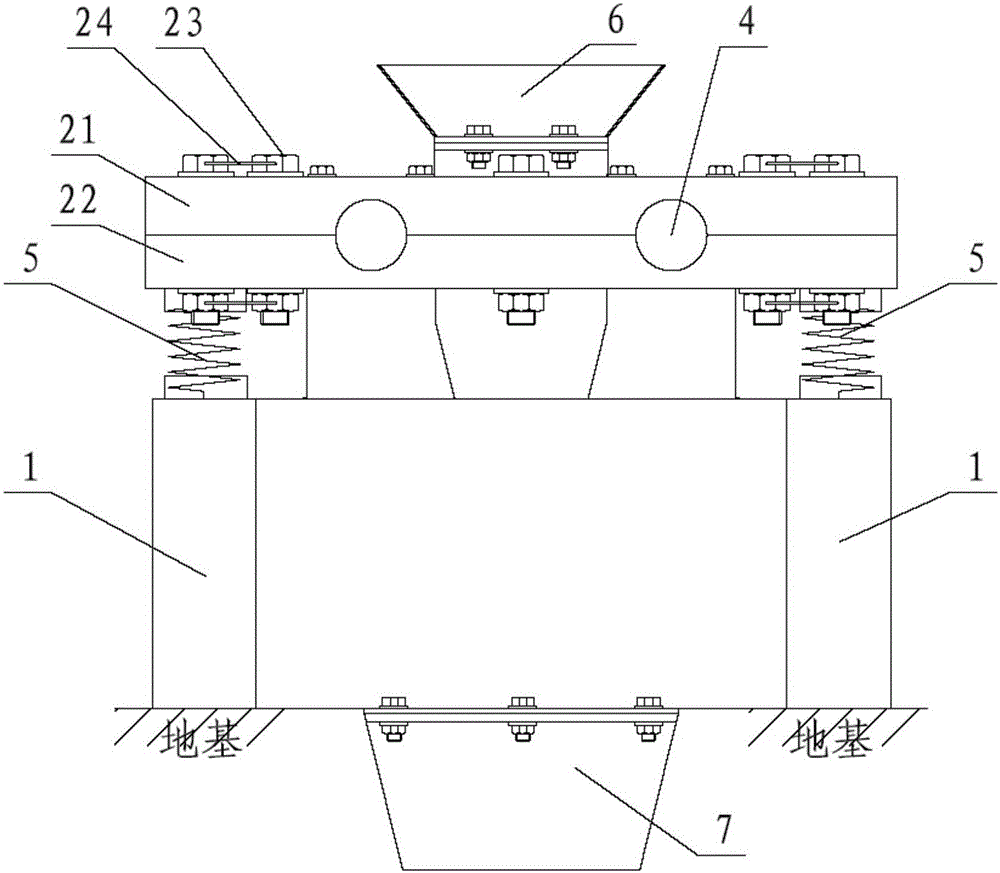

[0049] Such as Figure 1 to Figure 4 As shown, a vibrating self-synchronizing crusher with double exciters specifically includes a frame 1, a body assembly 2, two working movable jaw assemblies 3 and a torsion shaft 4 in structure, the frame 1 is set on the foundation, and the body assembly 2 By being installed on the top of the frame 1, both ends of the torsion shaft 4 are fixed on the body assembly 2, and the two working movable jaw assemblies 3 are fixed on the middle of the torsion shaft 4, and are symmetrically arranged below the body assembly 2 in the frame 1; A crushing cavity is formed between the symmetrically arranged working movable jaw assemblies 3 . The material inlet 6 is set on the upper part of the body assembly 2; specifically, it is located at the center, and the material outlet 7 is located under the frame 1, specifically at the center. The material enters the crushing chamber through the material inlet 6 and passes through the crushing cavity The feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com