Jaw crusher with V-shaped crushing cavity

A technology of jaw crushers and crushing chambers, applied in grain processing, etc., can solve the problems of low output of fine jaw crushers, high content of needle-like materials, and affecting construction quality, etc., to achieve increased output, stable equipment operation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

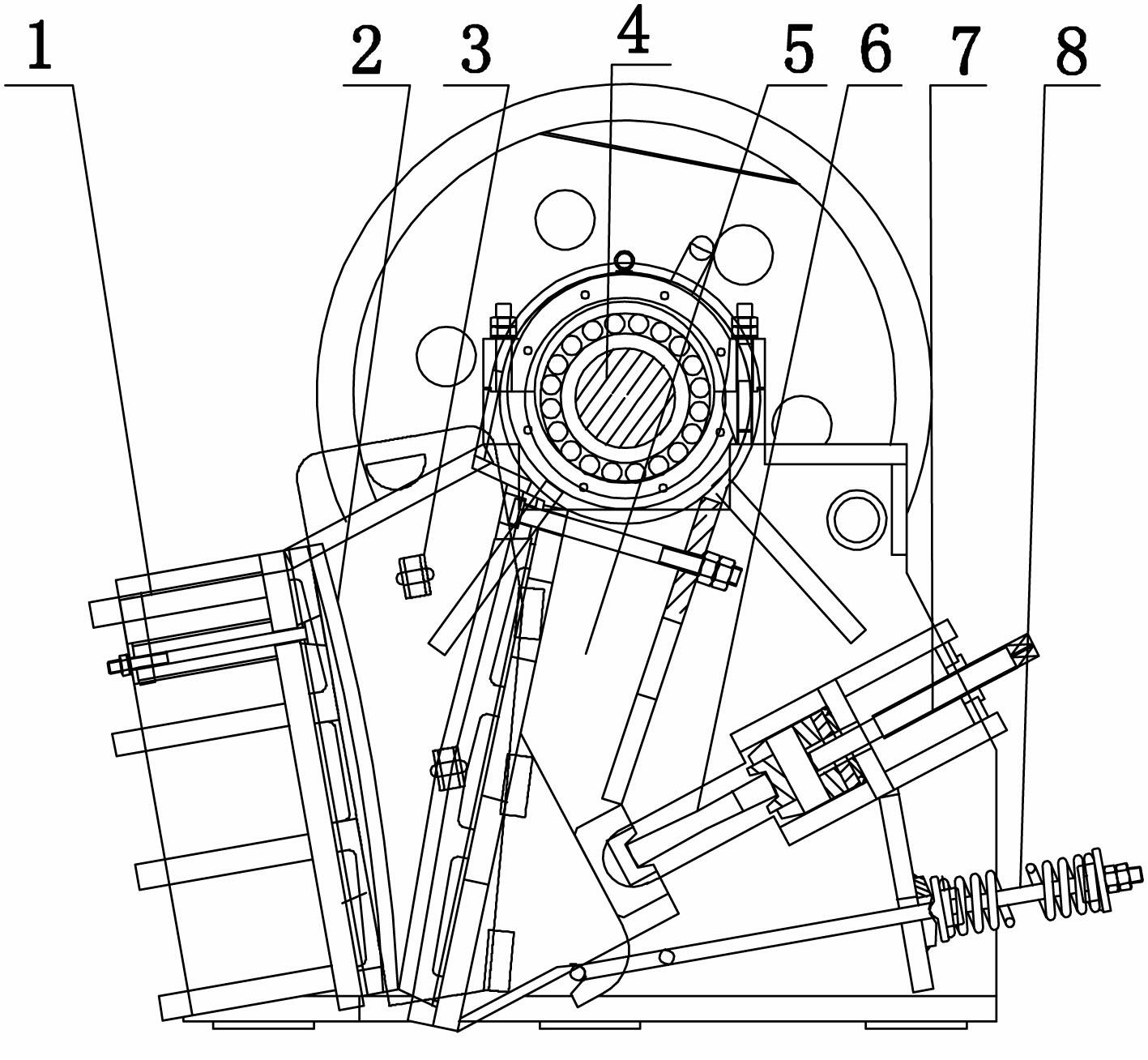

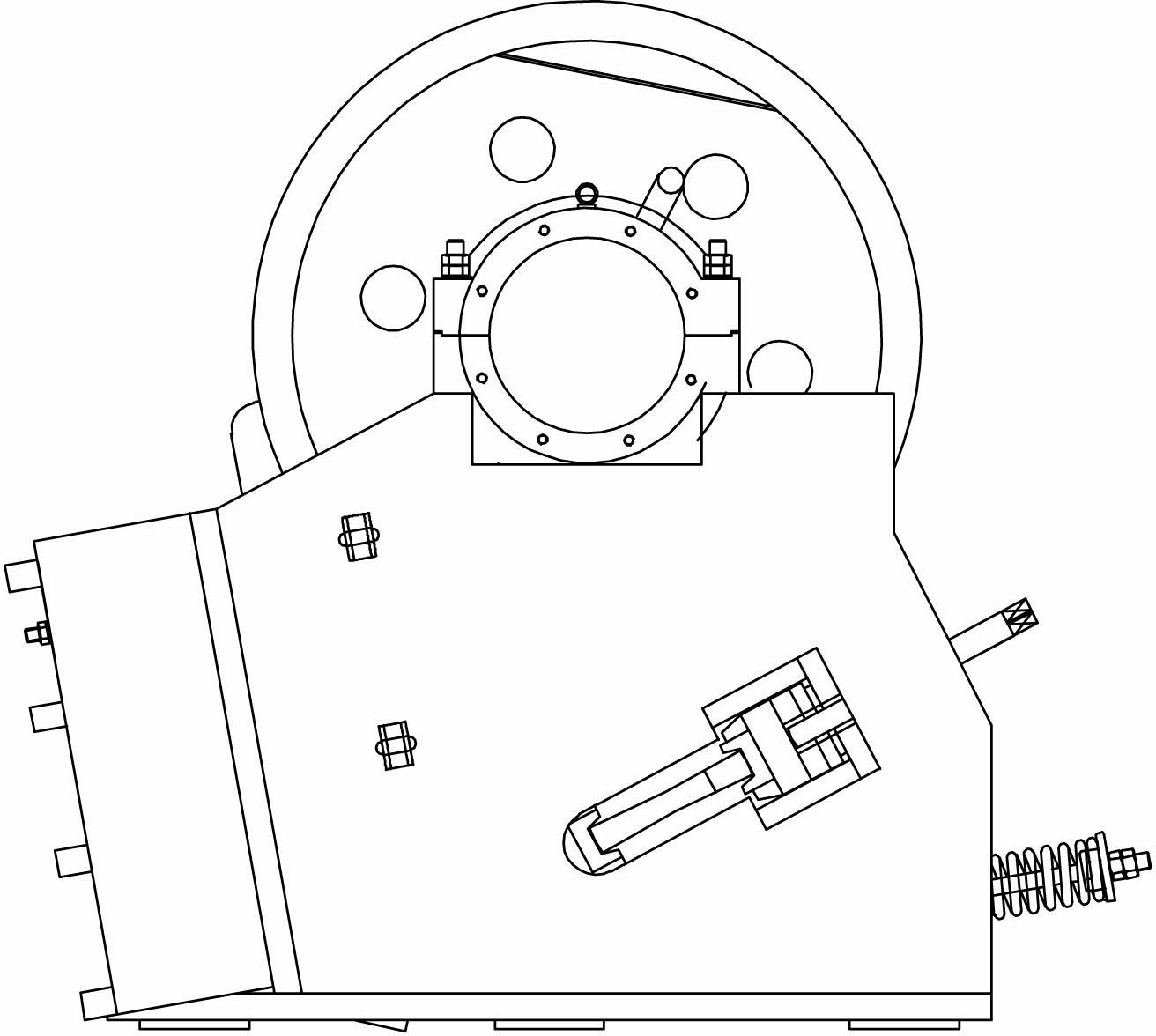

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 Among them, a jaw crusher with a V-shaped crushing cavity includes a frame 1, a side liner assembly 3, an eccentric shaft 4 is installed on the frame 1 through a bearing seat, and flywheels 9 are arranged at both ends of the eccentric shaft 4, one of which is 9 is also used as a transmission wheel for connection with the driving device, the movable jaw assembly 5 is installed on the eccentric shaft 4, and the fixed tooth plate 2 is installed at a position corresponding to the movable jaw assembly 5;

[0022] One end of the adjustment base 6 is installed in the slideway of the rear wall assembly of the frame 1, and the other end cooperates with the lower part of the movable jaw assembly 5;

[0023] One end of the pull rod 8 is connected with the movable jaw assembly 5, and the other end is installed in the rear wall assembly of the frame 1, and a spring is arranged on it.

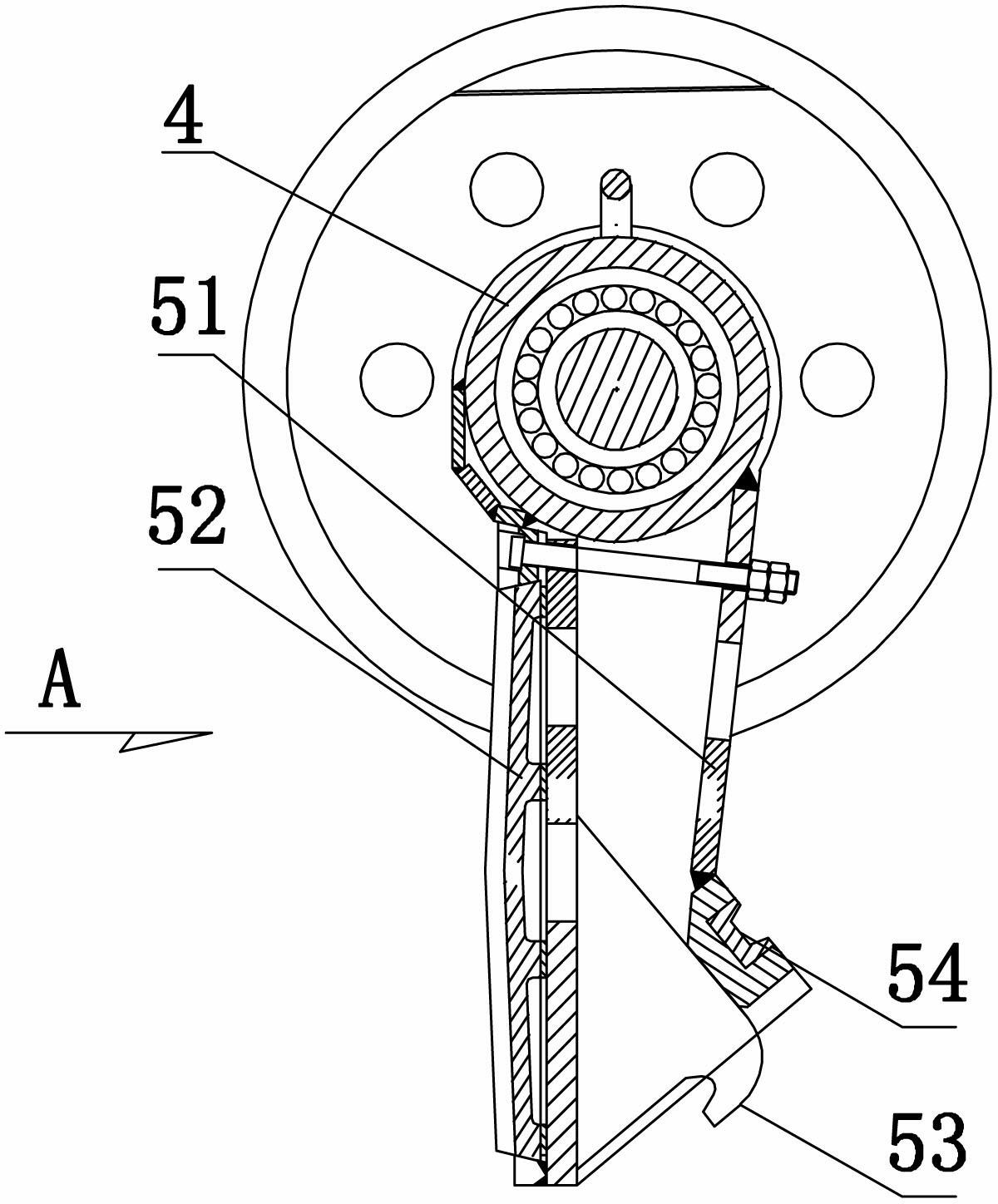

[0024] In the movable jaw assembly 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com