Anti-falling mechanism in case of breakage of crane hook steel wire rope

A wire rope and crane technology, applied in the field of hoisting machinery moving pulley device, can solve the problems of casualties, unbearable load, equipment damage, etc., and achieve the effects of avoiding falling incidents, reasonable structure and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

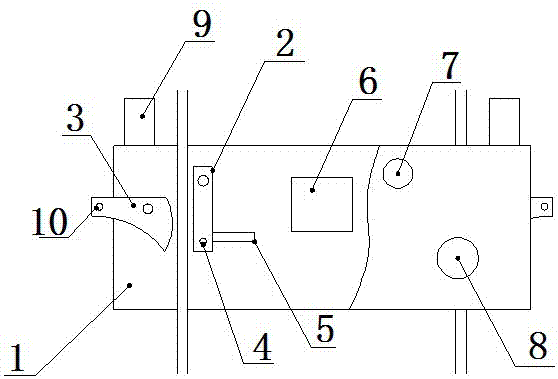

[0014] Such as figure 1 As shown, a crane hook wire rope broken rope anti-falling mechanism, it includes a wire rope splint 1, the steel wire rope splint 1 is respectively connected with a movable jaw 2 and an engaging tooth 3 matched with the movable jaw 2 through a pin shaft, The lower part of the movable jaw 2 is provided with a locking hole 4, and the lower part of the movable jaw 2 is connected with an electric push rod 5, and the described electric push rod 5 is connected with a controller 6 through a signal line, and the described controller 6 Connect with the wire rope splint 1 by bolts, the output end of the controller 6 is respectively connected with the alarm 7 and the electromagnetic lock 8 matched with the movable jaw 2 through the signal line, and the alarm 7 and the electromagnetic lock 8 are all arranged on the wire rope On the outer wall of the splint 1 , the input end of the controller 6 is connected with a speed measuring device 9 through a signal line, and ...

Embodiment 2

[0017] Such as figure 1 As shown, a crane hook wire rope broken rope anti-falling mechanism, it includes a wire rope splint 1, the steel wire rope splint 1 is respectively connected with a movable jaw 2 and an engaging tooth 3 matched with the movable jaw 2 through a pin shaft, The lower part of the movable jaw 2 is provided with a locking hole 4, and the lower part of the movable jaw 2 is connected with an electric push rod 5, and the described electric push rod 5 is connected with a controller 6 through a signal line, and the described controller 6 Connect with the wire rope splint 1 by bolts, the output end of the controller 6 is respectively connected with the alarm 7 and the electromagnetic lock 8 matched with the movable jaw 2 through the signal line, and the alarm 7 and the electromagnetic lock 8 are all arranged on the wire rope On the outer side wall of the splint 1, the input end of the controller 6 is connected with a speed measuring device 9 through a signal line, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com