Novel jaw crusher for crushing calcium carbide at high temperature of 400 DEG C

A jaw crusher and crusher technology, applied in mechanical equipment, engine components, engine lubrication, etc., to improve safety and environmental protection, facilitate transportation, and reduce dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

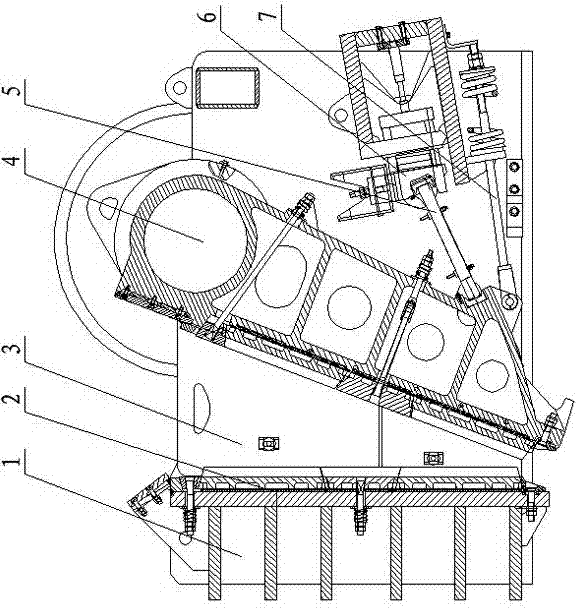

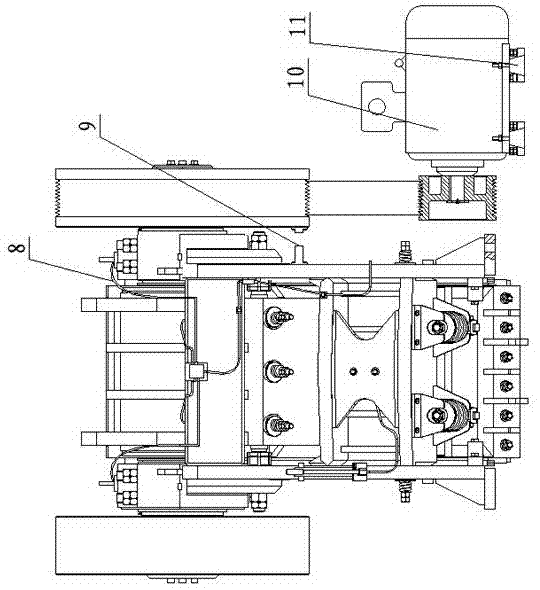

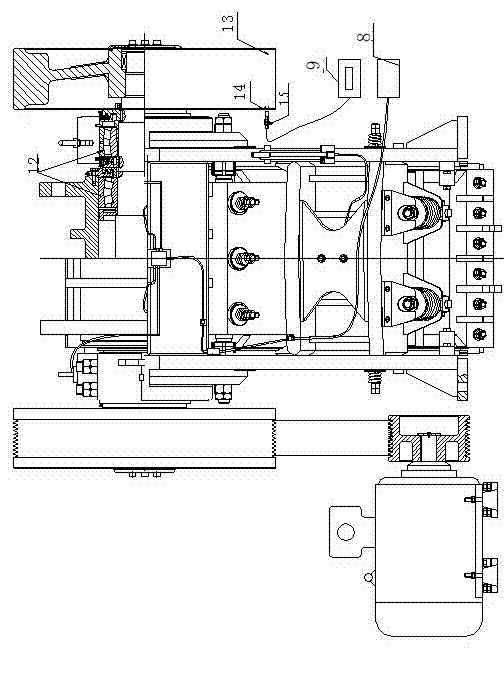

[0052] The invention discloses a new type of jaw crusher for crushing 400°C high-temperature calcium carbide. The design idea is: apply a heat-insulating coating around the crushing cavity to prevent the heat in the crushing cavity from transferring to the outside of the frame and bearings, and use high-temperature-resistant bearings. , An automatic lubricating system 8 is provided on the drive bearing 12 of the crusher to directly crush calcium carbide at a temperature of about 400°C. The structure of the crusher is shown in the appendix Figure 1-5 . The so-called crusher drive bearing 12 of this machine has 4 disk bearings in total, one disk at the connection between the two ends of the movable jaw body and the eccentric shaft, one disk at the connection between the belt pulley and the eccentric shaft, and one disk at the connection between the flyw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com