Automatic pipe laying machine

A pipe-arranging machine and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high error rate, high product loss rate, high labor intensity, and high labor cost, so as to reduce labor costs, improve work efficiency, and operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

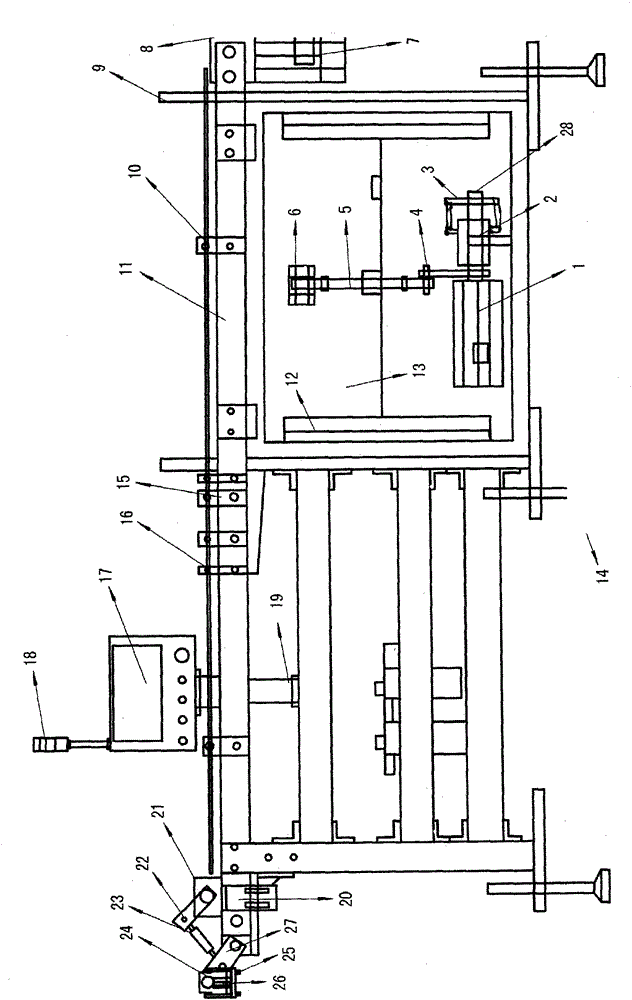

[0025] see figure 1 , The automatic pipe arrangement machine of the present invention is composed of four main structures: a hose jacking and feeding mechanism, a belt conveying line mechanism, a positive and negative head identification mechanism and a rotation and translation mechanism.

[0026] The hose jacking and feeding mechanism is located at the lower part of the front side of the pipe arrangement machine. The hose jacking and feeding mechanism includes a jacking motor 1 and a stepped feeding plate 13, and the connection between the jacking motor 1 and the stepped feeding plate 13 are connected by conduction facilities. Described conduction facility is made up of primary sprocket 2, driven sprocket 3, crank 4, connecting rod 5 and shaft support 6. The main sprocket 2 is installed on the shaft of the jacking motor 1, the main sprocket 2 drives the driven sprocket 3 through the chain, the connecting shaft 28 of the driven sprocket 3 is connected with the crank 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com