Automatic blank removing machine for rough castings

A technology for scraping materials and blanks, which is applied in the field of automatic scraping machines for casting blanks, can solve the problems of low work efficiency, high labor intensity, and cannot realize automatic production, etc., and achieves the effect of saving labor, improving work efficiency, and reducing labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below.

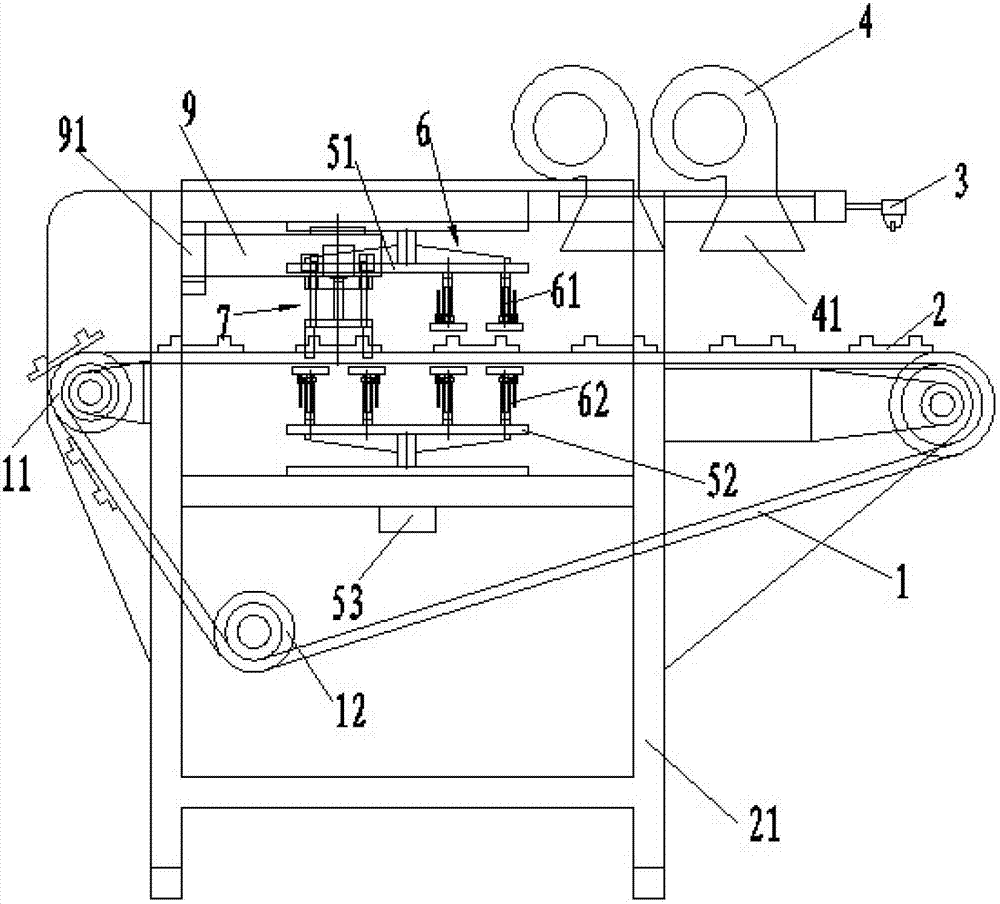

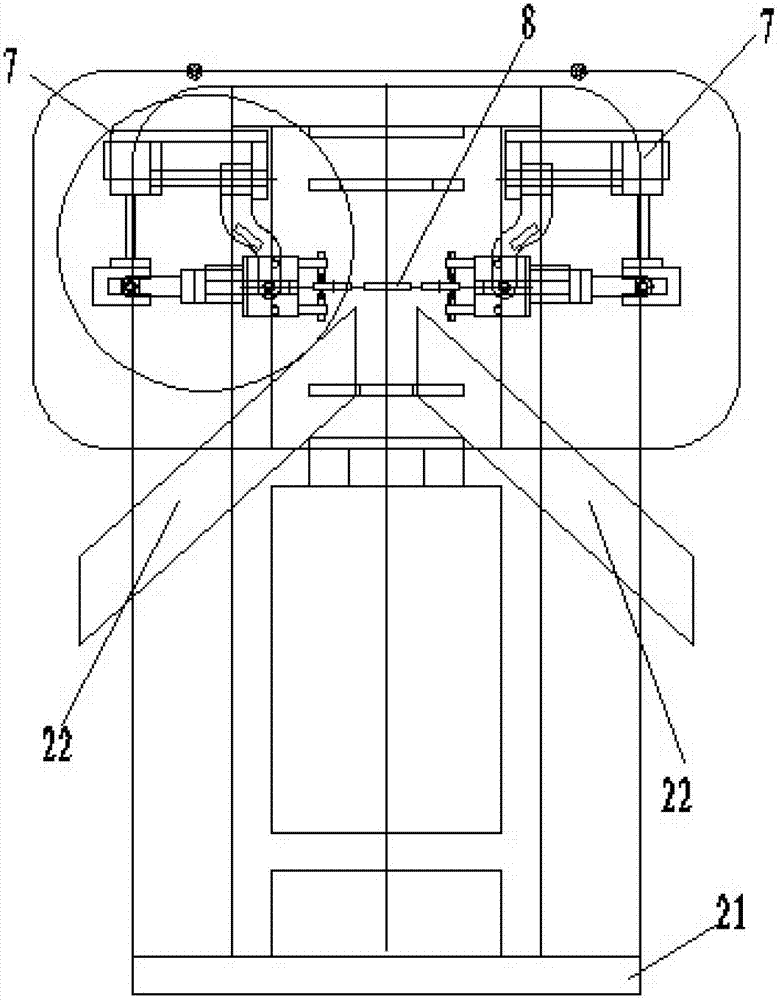

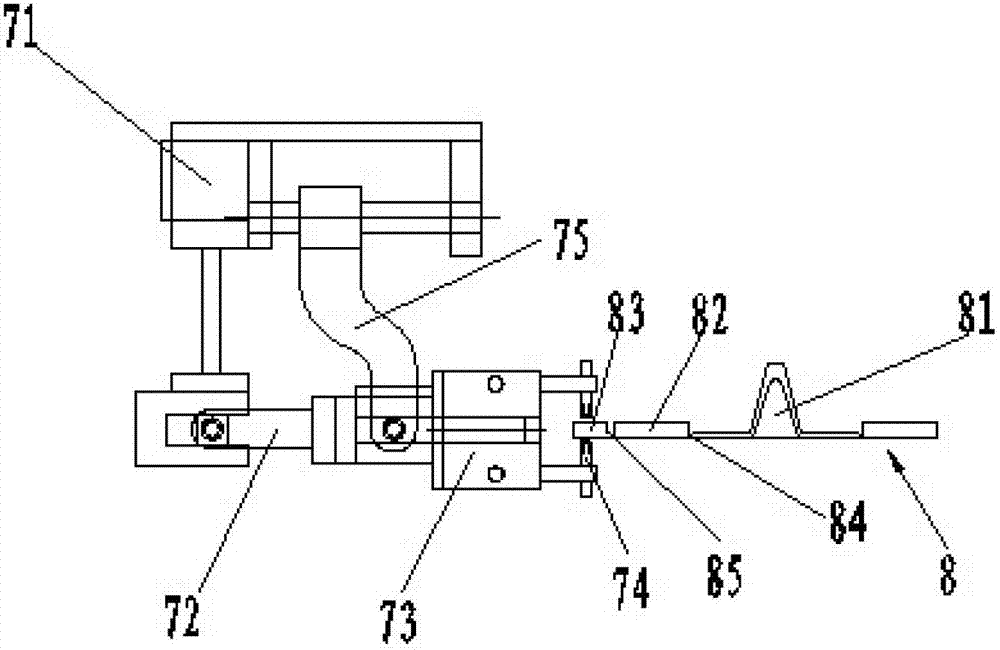

[0023] Such as figure 1 As shown, the present invention discloses an automatic pickling machine for casting blanks, which includes a control system and a conveyor chain 1 driven by a drive system, which is mounted on a frame 21 under tension by a sprocket 11 and a tension wheel 12, and driven The system is a stepping deceleration motor, the drive system makes the conveyor chain 1 step intermittently, and the clamps 2 for carrying the material are installed equidistantly on the conveyor chain 1, in the direction along the conveyor chain 1 travel A cooling station, a first grilling station and a second grilling station are arranged in sequence. When the conveyor chain 1 is suspended during operation, the clamp 2 is just positioned at the cooling station, the first grilling station and the second grilling station. At the second picking station, that is, the clamp 2 is suspended at each st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com