Microwave hot forming apparatus

A technology of hot-pressing forming and microwave heating device, applied in microwave heating, presses, manufacturing tools, etc., can solve the problems of low thermal efficiency of external heat sources, uneven heating of materials, long heat conduction time, etc., to achieve automatic continuous production, Fast heating speed and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

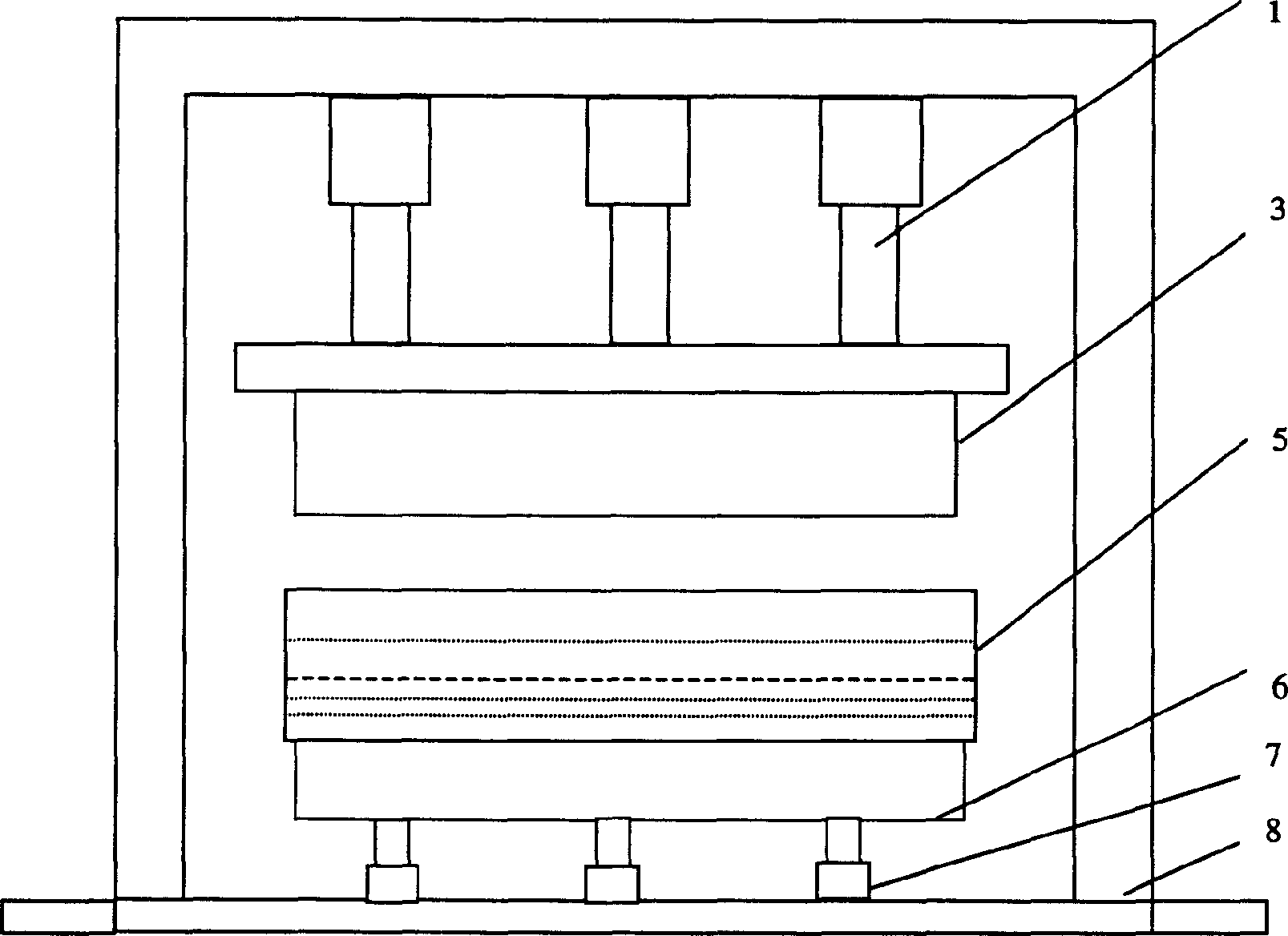

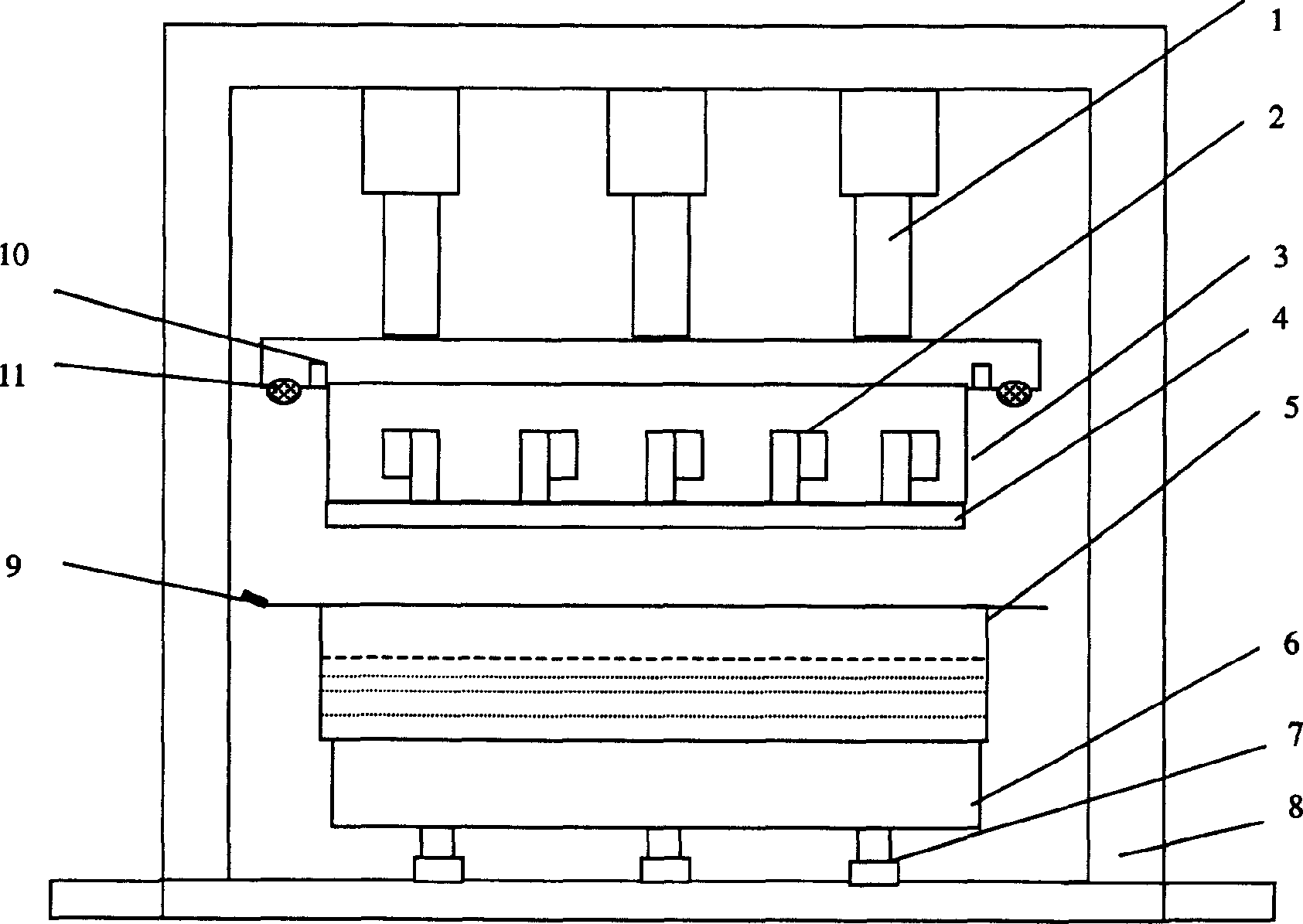

[0032] Embodiment 1: The present invention adopts the microwave energy feeding of the upper mold and the oil heating structure at the bottom of the lower mold

[0033] If the thickness of the wood fiber composite material is less than 150 mm and the area is about 6 square meters, 50 1kW / 2450MHz magnetrons can be evenly arranged in an orthogonal arrangement in the inner cavity of the upper steel mold 3, and the microwave control part consists of a The power control cabinet is under unified control. In the bottom cavity 6 of the lower mold 5, a traditional oil heating device can still be used. Microwaves act on the lower mold 5 through the energy feed port 12 on the bottom plate of the upper steel mold 3 and the microwave transparent window 4 made of quartz glass (or polytetrafluoroethylene plastic plate) with high strength and low dielectric loss of a certain thickness. The material absorbs microwaves, and its own dielectric loss heats up to achieve uniform and rapid heating a...

Embodiment 2

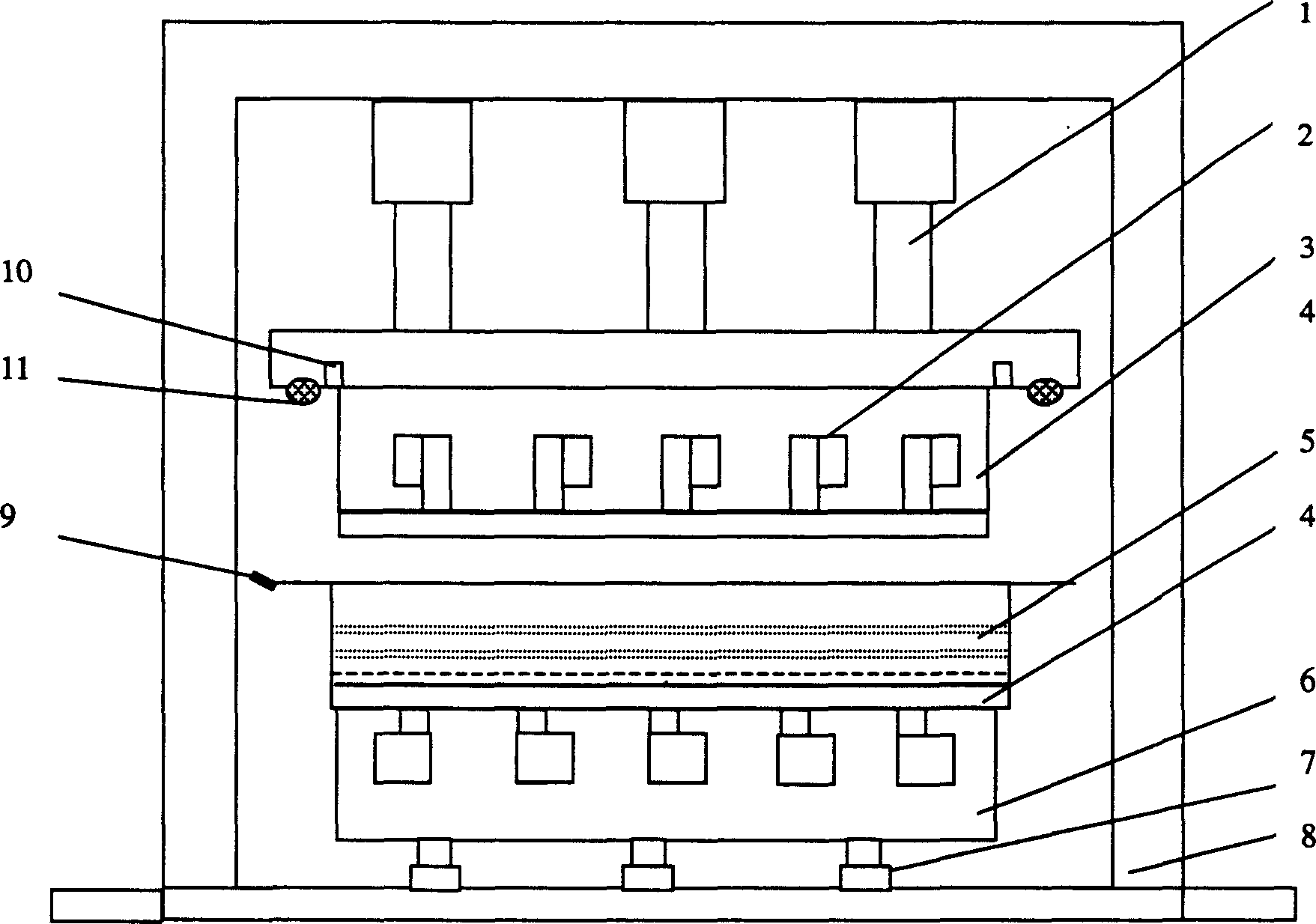

[0035] Embodiment 2: The present invention adopts the upper mold and the lower mold to set the microwave heating device structure at the same time

[0036] If the thickness of the material is more than 150 mm and less than 600 mm, and the area is about 6 square meters, 50 1kW / 2450MHz magnetron, its microwave control part is uniformly controlled by a power control cabinet. The microwave passes through the energy feed port 12 on the bottom plate of the upper steel mold 3 and the energy feed port 12 on the top plate of the bottom cavity 6 of the lower mold 5 and the quartz glass (or polytetrafluoroethylene) of high strength and low dielectric loss of a certain thickness. The microwave transparent window 4 made of plastic plate) acts on the material in the lower mold 5 up and down simultaneously, the material absorbs microwaves, and its own dielectric loss heats up so as to achieve uniform and rapid heating and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com