Sand production line

A production line, sand and gravel technology, applied to the separation of solids from solids by air flow, grain processing, chemical instruments and methods, etc., can solve the problems of difficult remote monitoring and unattended operation, high labor intensity of operators, and low degree of automation and other problems, to achieve the effect of easy unattended, good cleaning effect and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

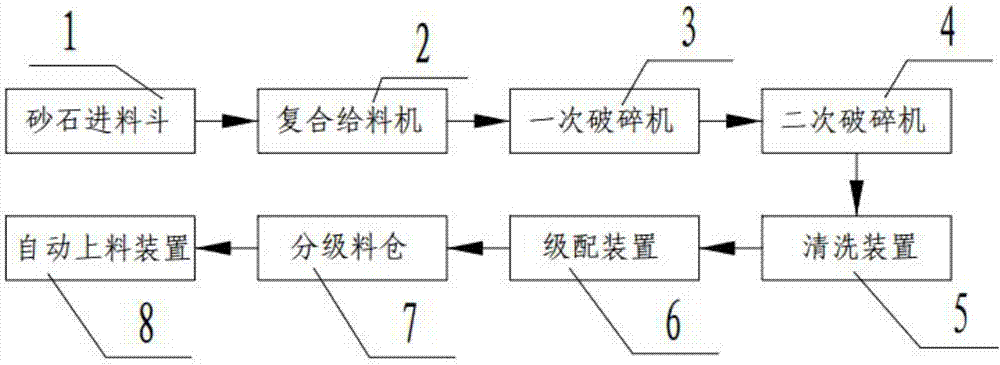

[0031] Embodiment 1: as Figure 1-Figure 11 As shown, a gravel production line includes a gravel feed hopper 1, a compound feeder 2, a primary crusher 3, a secondary crusher 4, a cleaning device 5, a grading device 6 and a grading bin 7, and the gravel The outlet of feed hopper 1 is connected to the feed end of compound feeder 2, the discharge end of compound feeder 2 is connected to the feed hopper of primary crusher 3, and the collecting hopper of primary crusher 4 is connected to the secondary feeder through a conveyor belt. The feed hopper of the secondary crusher 4, the collecting hopper of the secondary crusher 4 is connected to the cleaning device 5 through the conveyor belt, the cleaning device 5 is connected to the grading device 6 through the conveyor belt, and the grading device 6 is connected to the grading bin through the conveyor belt 7. An automatic feeding device is installed above the grading bin 7.

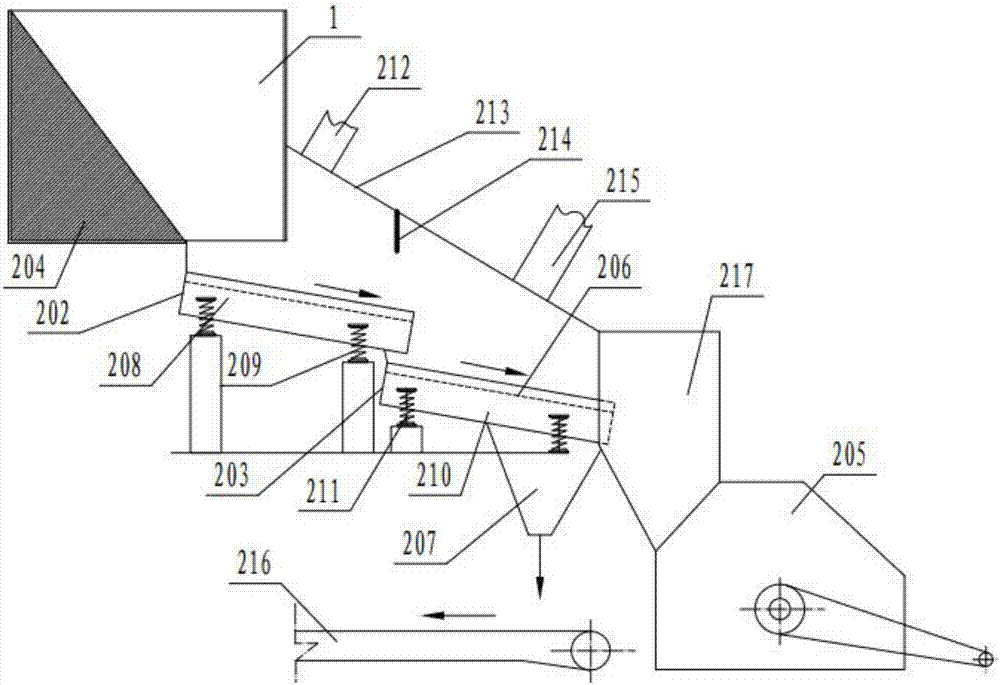

[0032] Preferably, the above compound feeder 2 includes a ...

Embodiment 2

[0053] Embodiment 2: as Figure 7 As shown in —9, the above-mentioned production line also includes an intelligent monitoring device, which includes a remote monitoring terminal. The remote monitoring terminal is connected to the on-site controller at each process of sandstone production through a network module. The on-site controller is connected with a camera, and the camera is used for Shoot the working conditions of the process, and monitor the video of the process collected by the on-site controller through the remote monitoring terminal to realize centralized management of sand and gravel on-site production, reduce inspection time, reduce inspection labor intensity, and greatly improve inspection efficiency.

[0054] Preferably, the above-mentioned camera 701 is installed on the wall 703 through a mounting bracket 702. The mounting bracket 702 includes a support rod 704, a support plate 705 and a support sleeve 706, and the two ends of the support rod 704 are respectivel...

Embodiment 3

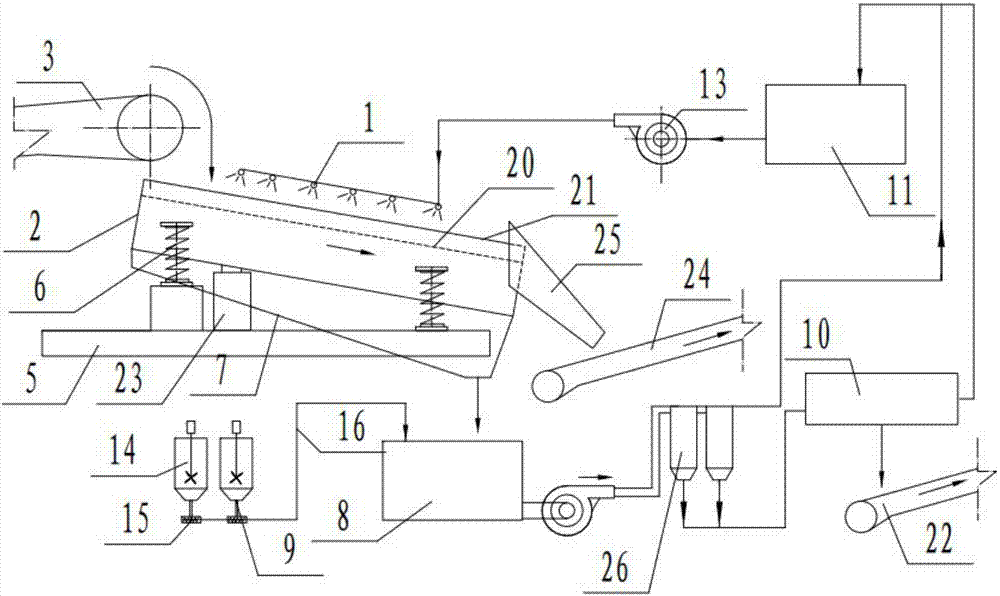

[0058] Embodiment 3: The above-mentioned gravel production line also includes a stone powder recovery device, which includes a plurality of vibrating screens and a plurality of crushers, each vibrating screen adopts a closed baffle cover box, and an exhaust pipe is connected to the closed baffle, The side wall of the discharge collecting hopper of each crusher is provided with a suction pipe 2, and the suction pipe 1 and the suction pipe 2 are connected to the suction fan, and the dust absorbed by the suction fan is transported to the belt conveyor through the screw feeder, and the belt conveyor The tail end of the conveyor is connected to the silo, which is fixedly connected to the ground through a support frame. The bottom of the silo is a conical structure and is equipped with a discharge pipe. The discharge pipe is equipped with a valve, and the upper end of the discharge pipe is provided with multiple blowing pipes. , a plurality of blowing pipes are arranged circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com