Foamed reinforced plastic winding pipe, manufacturing method of foamed reinforced plastic winding pipe and special equipment for foamed reinforced plastic winding pipe

A technology of reinforced plastics and manufacturing methods, applied in mechanical equipment, pipes, rigid pipes, etc., can solve the problems of unreliable combination of steel strips and plastics, high production costs, corrosion of steel strips, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

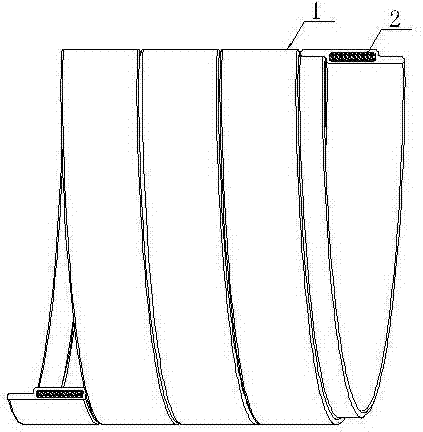

[0027] Embodiment 1, a kind of foam reinforced plastic winding pipe, refer to figure 1 , is made of plastic profile 1 by spiral winding, and there is a foam layer 2 between the outer wall and the inner wall of the plastic profile 1, which constitutes a structure of the present invention.

Embodiment 2

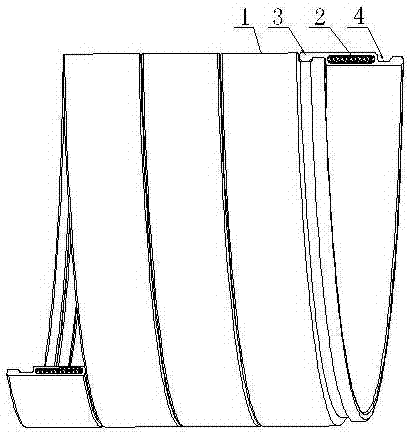

[0028] Embodiment 2, a kind of foam reinforced plastic winding pipe, refer to figure 2 , on the basis of Embodiment 1, ribs 3 and retaining grooves 4 are respectively provided at both ends of the plastic profile 1, and the others are identical to Embodiment 1.

Embodiment 3

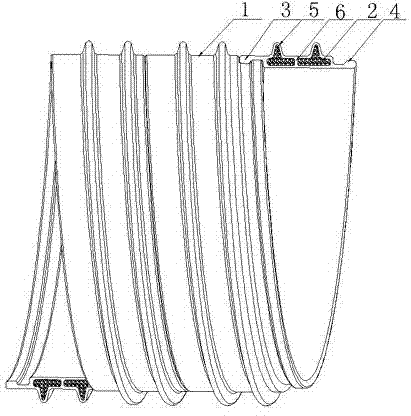

[0029] Embodiment 3, a kind of foam reinforced plastic winding pipe, refer to image 3 , is that the tube outer wall of the plastic profile 1 is provided with reinforcing ribs 5, and the foam layer 2 between the tube outer wall and the inner wall of the plastic profile 1 is provided with a partition 6, and the others are identical to embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com