Combining arrangement device for multiple kinds of boards

A technology for sorting devices and sheet materials, which is applied in the field of automation, and can solve problems affecting production efficiency, many processes, and inability to realize fully automated production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

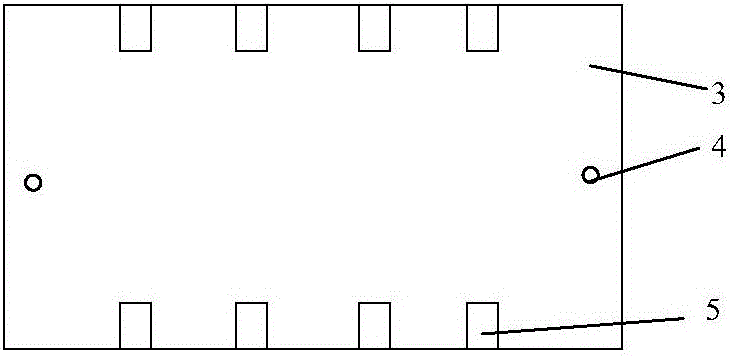

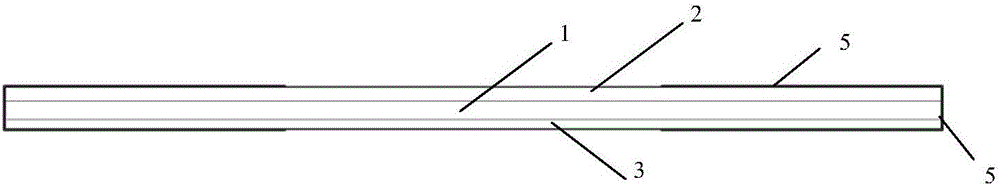

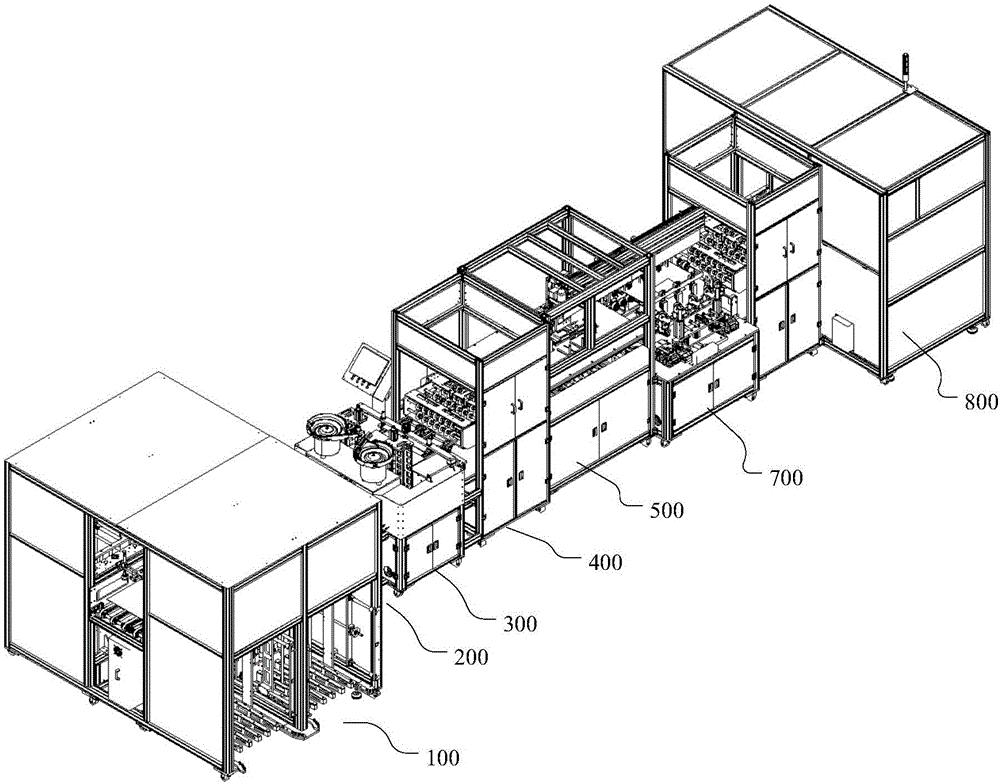

[0113] Such as Figure 1~Figure 3 As shown, a composite finishing device for various sheet materials, which includes a feeding and conveying mechanism 100, a conveying and aligning mechanism 200, a centering punching and pinning mechanism 300, a turning mechanism 400, a conveying and centering rotation mechanism 500, and a metal sheet feeding Mechanism 600, three-sided adhesive tape mechanism 700 and unloading mechanism 800, the conveying alignment mechanism 200, the centering punching and pinning mechanism 300, the turning mechanism 400, the conveying centering rotation mechanism 500, the metal sheet feeding mechanism 600, the three-sided pasting mechanism The tape mechanism 700 is sequentially arranged between the feeding and conveying mechanism 100 and the unloading mechanism 800; the feeding and conveying mechanism 100 makes the product board 1 below and stacks the product board 1 and the isolation board 3 together to obtain a composite isolation product board, Transport t...

Embodiment 2

[0115] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, the feeding and conveying mechanism 100 includes a first conveying platform 101, a product plate stacking rack 102, an isolation plate stacking rack 103 and a manipulator handling module 104, and the manipulator handling module 104 is located on the first conveying platform 101, product Above the plate stacking rack 102 and the isolation plate stacking rack 103, the manipulator handling module 104 moves and stacks the product plate 1 on the product plate stacking rack 102 and the isolation plate 3 on the isolation plate stacking rack 103 respectively on the first On the conveying platform 101, a composite isolation product board is obtained.

[0116] The product plate stacking frame 102 and the isolation plate stacking frame 103 are respectively provided with a lifting platform 110, and the lifting platform 110 includes a longitudinal beam 111 and a carrier 112, and the longitudinal beam 111 is provid...

Embodiment 3

[0120] On the basis of Example 2, such as Figure 6 As shown, the conveying alignment mechanism 200 includes a second conveying platform 201, the output end of the second conveying platform 201 is provided with a first blocking mechanism 202, and the first blocking mechanism 202 includes a first blocking member 221 and a first Block the lifting member; the middle part of the second delivery platform 201 is provided with an alignment mechanism 203 on its left and right sides, the first delivery platform 101 transports the composite isolation product board to the second delivery platform 201, and the first stop The lifting member drives the first blocking member 221 to move upwards, preventing the composite isolated product board from moving with the second conveying platform 201, and the alignment mechanism 203 moves the product board 1, The isolation plate 3 is aligned; the first blocking lifting member is the first blocking lifting cylinder;

[0121] The alignment mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com