Light-penetrating concrete preparation process based on optical fibers wrapped with mortar

A technology of light-transmitting concrete and preparation technology, which is applied to optical fiber light guides, manufacturing tools, light guides of lighting systems, etc., can solve problems such as heavy workload, difficulty in grasping the density of optical fibers, and difficulty in controlling the distance between optical fibers, so as to reduce production costs and save The effect of reducing workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0034] The preparation process of the light-transmitting concrete based on optical fiber coating in the present invention is as follows:

[0035] According to the weight ratio cement: water: viscosifier: accelerator = 1:0.3~0.6:0.0003~0.001:0.005~0.02 to mix the slurry;

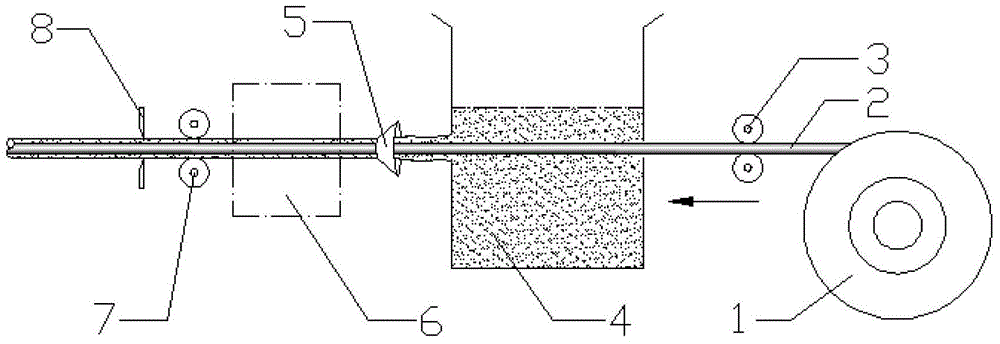

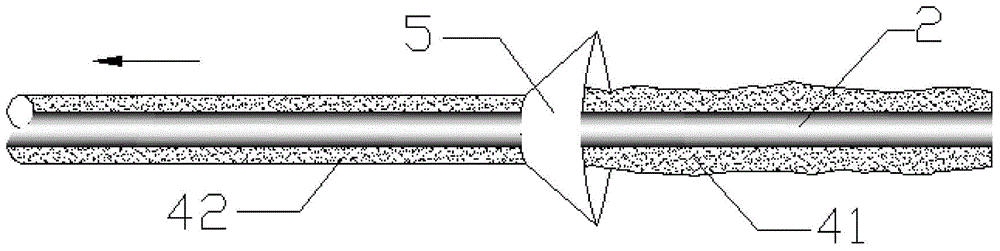

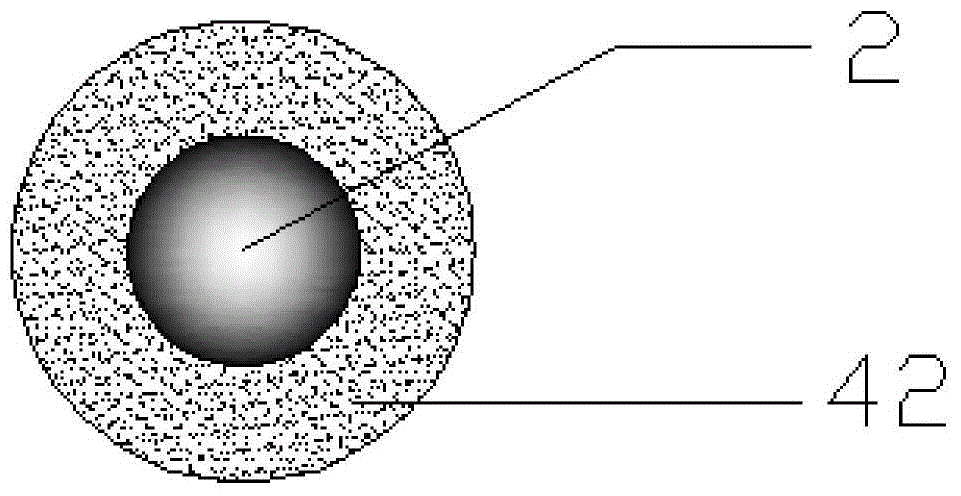

[0036] Refer to attached figure 1 , 2 , 3, the optical fiber 2 is pulled out from the optical fiber coil 1 by the optical fiber guide wheel 3, and the straightened optical fiber 2 is passed through the cement slurry box 4 so that the slurry adheres and wraps on the surface of the optical fiber; the viscosity of the slurry is 45cPa, The thickness of the slurry layer is about 0.8mm, and there is no dripping from the optical fiber; due to the influence of gravity, optical fiber vibration and other factors, the thickness of the slurry l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com