Automatic production line for lightweight wall materials

An automatic production line and wall material technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of large space occupation, many operators, discontinuous production process of lightweight wall materials, etc., to improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

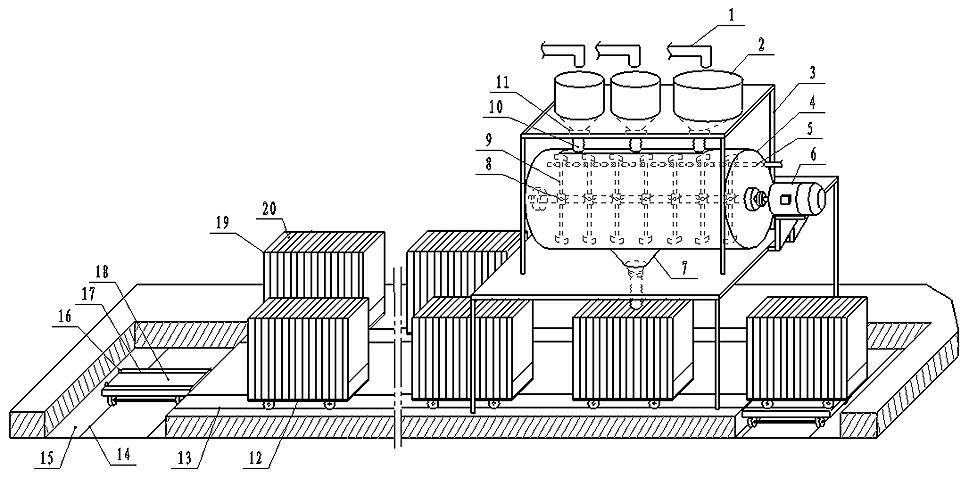

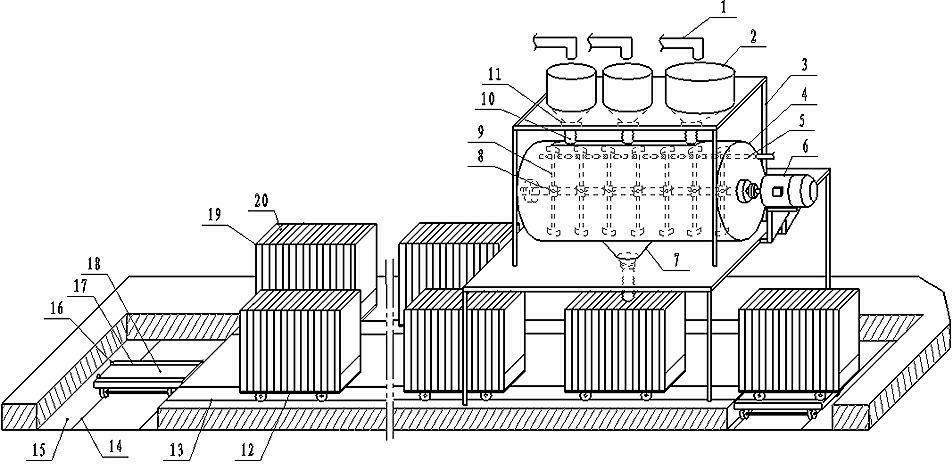

[0012] Example: such as figure 1 As shown, an automatic production line for light wall materials mainly includes four parts: a feeding system, a mixing system, a material transportation system and a forming mold. The feeding system is composed of a silo and a feeding pipe 1, and the feeding pipe 1 is connected The silo, the silo is arranged on the edge of the work site, the agitator 4 of the mixing system is installed on the support 3, the upper support of the agitator 4 is installed on the feed hopper 2, and the discharge port 7 is installed below, and the agitator 4 is installed with The water spray pipe 5 and the feed pipe 1 are installed above the agitator feed hopper 2, the shell of the agitator 4 is fixed on the bracket 3, and the rotating shaft 8 is installed in the middle of the shell, and the rotating motor 6 is installed at one end of the rotating shaft 8, and the middle part is installed The stirring arm 9 has a fixed feed inlet 10 above the shell of the agitator 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com